Prefabricated cement pavement slab for quick pavement repair

A cement road and panel technology, which is applied to pavement, roads, roads and other directions paved with prefabricated blocks, can solve the problems of affecting the normal operation of traffic and damaging economic benefits, so as to save maintenance time, eliminate early failures, and achieve high concrete quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the present invention will be further described below in combination with the accompanying drawings.

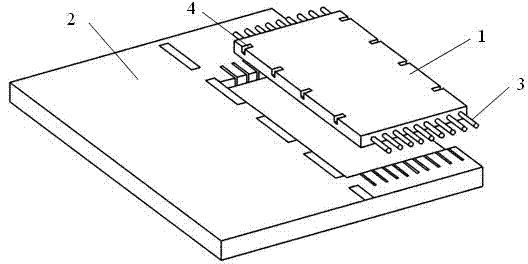

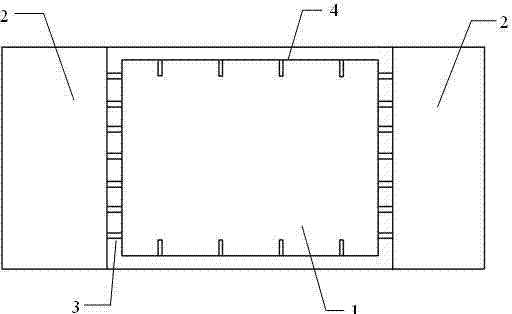

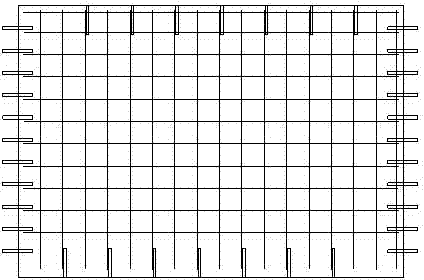

[0025] Such as Figure 1 to Figure 4 As shown, a prefabricated cement concrete road slab for rapid maintenance of road surfaces includes a prefabricated concrete panel 1, and two layers of metal reinforcement bars are distributed in a criss-cross pattern inside the precast concrete panel 1, and the precast concrete panel 1 is in the driving direction. Dowel bars 3 are evenly protruded from the middle of both ends of the panel, and tie bar grooves 4 are evenly arranged on both longitudinal sides of the precast concrete panel 1 .

[0026] The metal reinforcement includes an upper metal reinforcement 11 composed of No. 4 epoxy resin coated steel bars and a lower metal reinforcement 12 composed of No. 4 ordinary steel bars from top to bottom, wherein the distance between the upper metal reinforcement 11 and the precast c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com