Stay cable and bridge tower anchored prefabricated prestressed concrete anchor beam structure

A technology of concrete and cable stays, applied in the field of anchoring systems, can solve problems such as difficult manufacturing, difficult manufacturing and transportation, and difficult dehumidification, and achieve low maintenance costs and expenses, small occupied space, and reduced steel consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

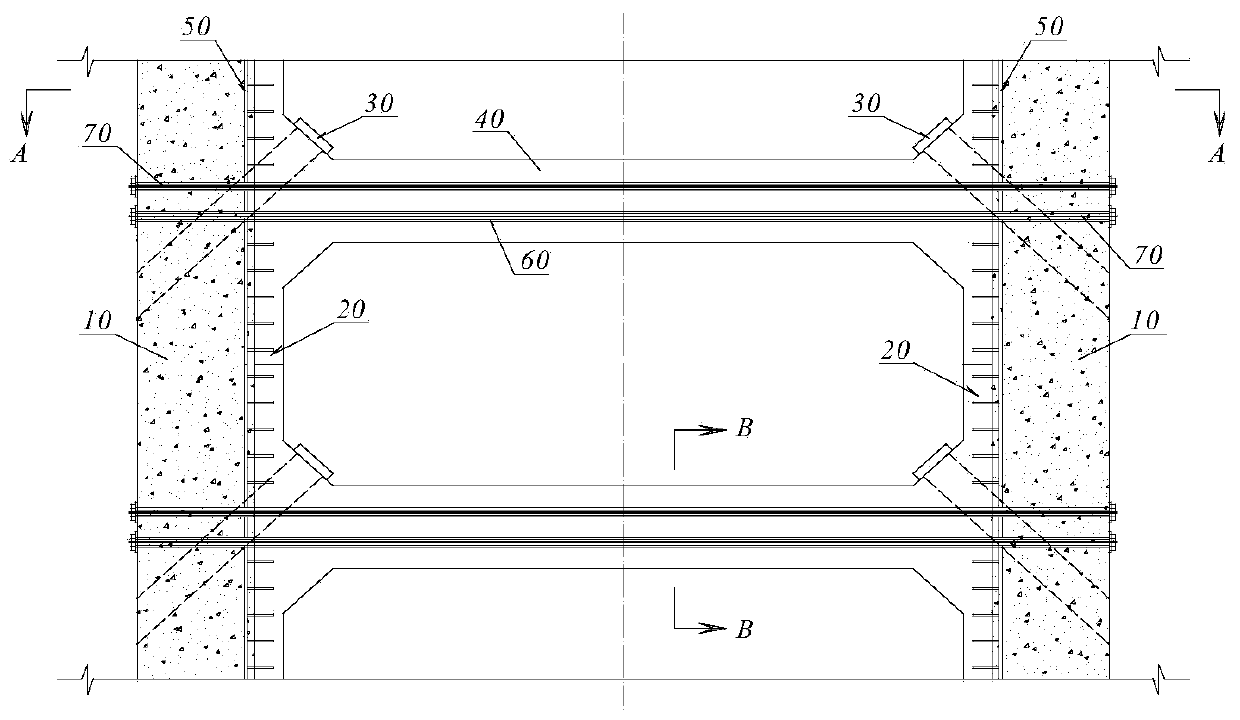

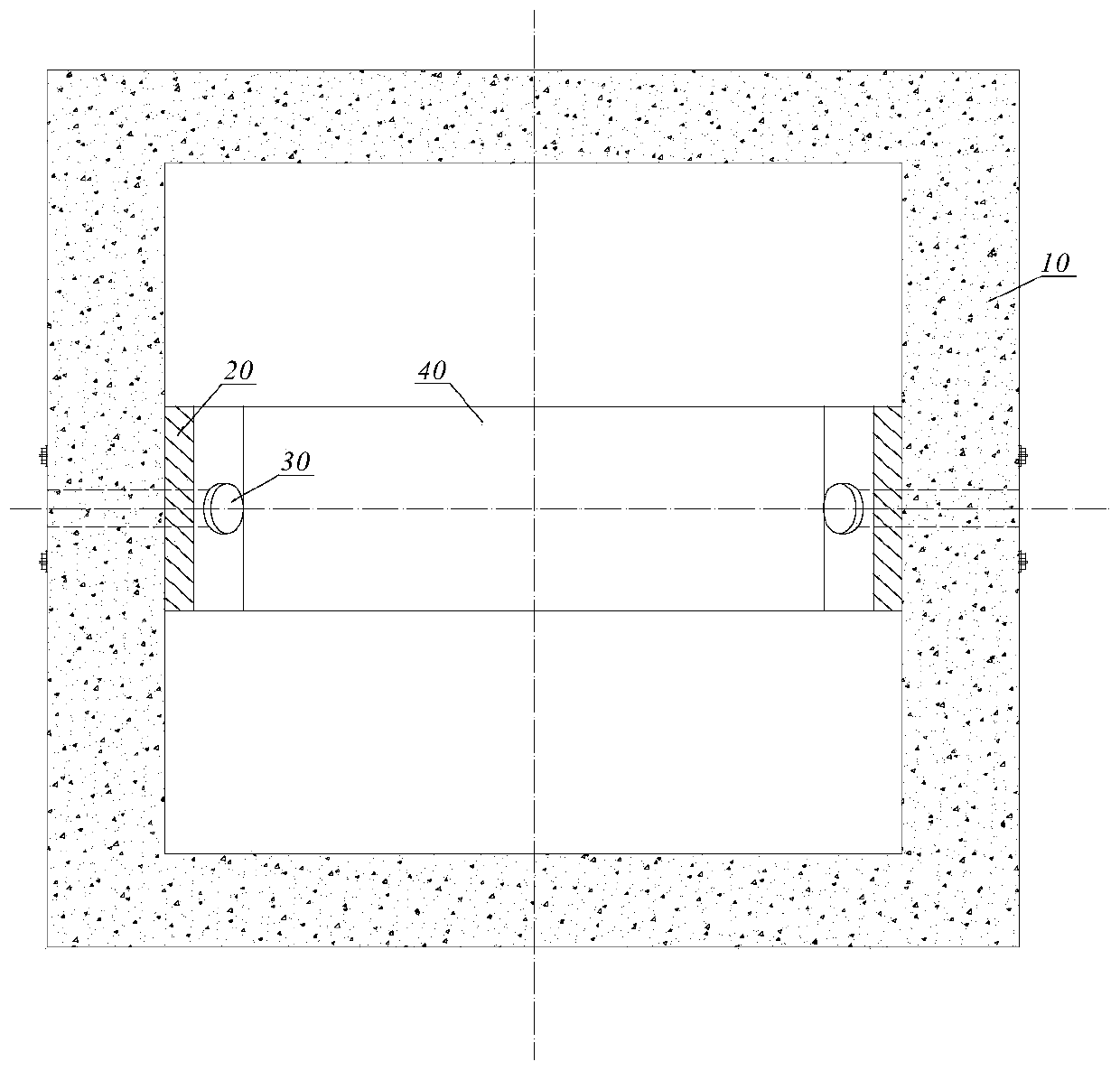

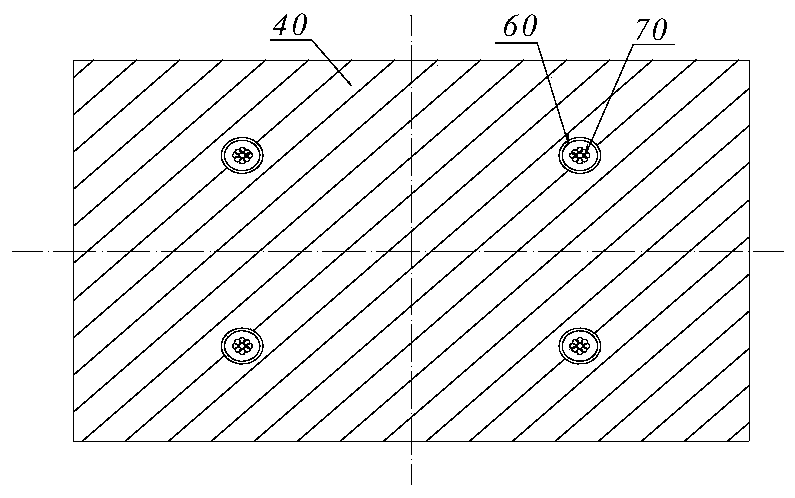

[0031] Figure 6 and Figure 7 Shown is an existing steel anchor girder structure anchored by stay cables and pylons. Its structure and construction process are as follows:

[0032] 1. Manufacture the steel corbel 21 and weld the shear nails 51 on the vertical plate at the steel structure processing factory; manufacture the steel anchor box 31 and the steel anchor beam 41, and weld the shear nails on the vertical plate of the steel anchor box 31 61. The steel corbels and steel anchor beams manufactured in the project are transported to the site respectively.

[0033] 2. Use tower cranes to install steel corbels 21 and pour concrete 11 for bridge tower segments, install steel anchor boxes 31 and steel anchor beams 41 to form a whole.

[0034] The deficiencies in the existing steel anchor beam structure are mainly reflected in the high cost of steel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com