Tubular busbar post insulator overhaul platform

A technology for pillar insulators and maintenance platforms, which is applied in the installation of cable installation devices, electrical components, cables, etc., can solve the problems of wasting maintenance funds, lack of reliable safety protection, and calling large cranes, etc., to achieve optimal combination, improve maintenance conditions, The effect of saving maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will be described in conjunction with the accompanying drawings and specific embodiments.

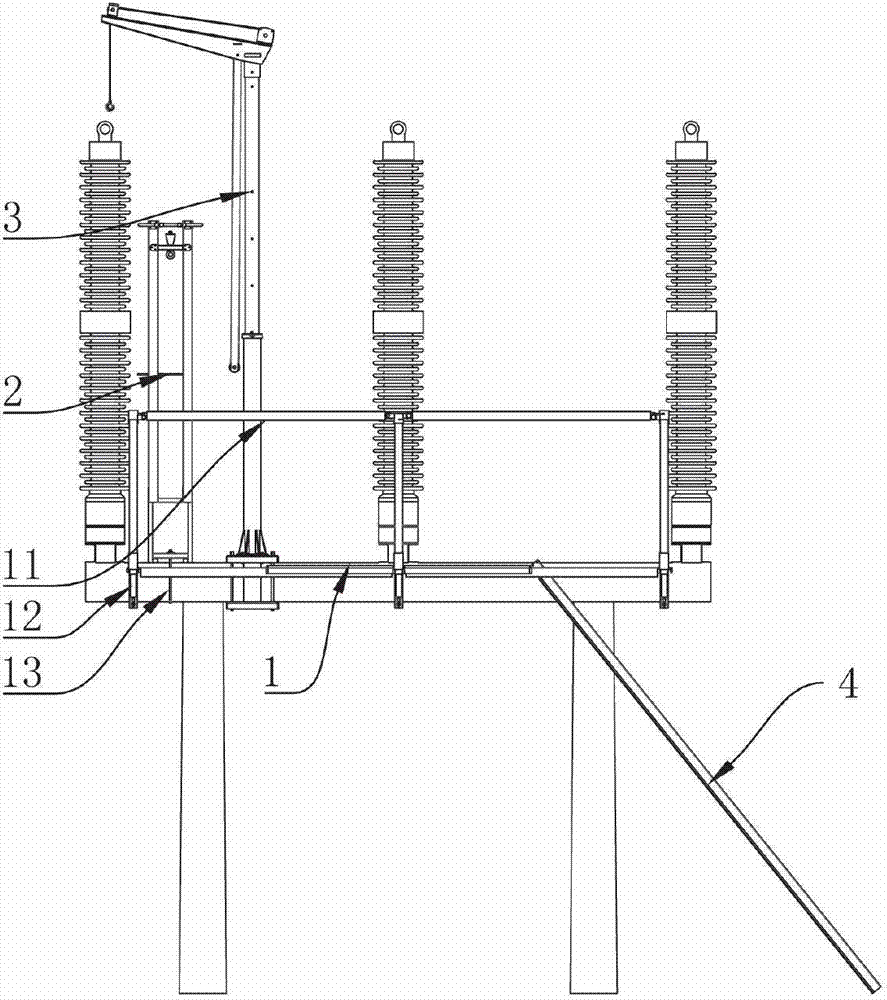

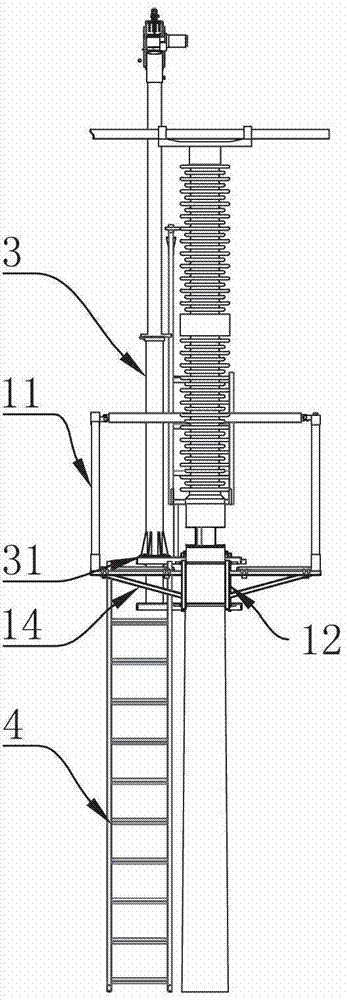

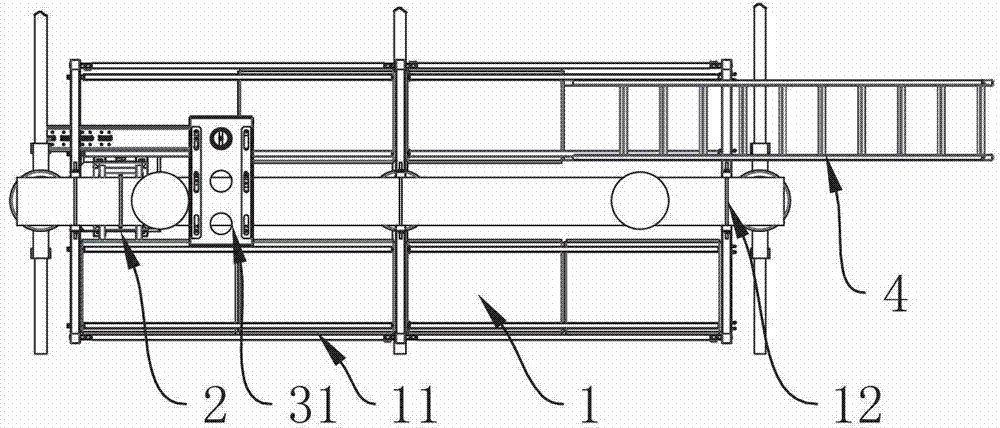

[0014] see Figure 1 to Figure 3 . The maintenance platform for tubular busbar post insulators described in this embodiment is installed on a portal frame. The maintenance platform includes a large low platform 1, a small high platform 2 and a miniature crane 3. More practical needs, the size of the large low platform 1 and the size and height of the small high platform can be selected to suit the size. The low large platform 1 is on the same plane as the cross bar of the portal frame, and the portal frame cross bar also serves as a part of the low large platform 1 during use. The large platform 1 at the low position, the small platform 2 at the high position and the miniature crane 3 can all be fixed on the portal frame.

[0015] The bottom of the large low platform 1 is spliced by a plurality of insulating base plates, and each base plate is erected on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com