Device for rotationally locking the supporting roll balanced architecture of roll stands

A technology of rolling mill stand and balance cylinder, which is applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problems of non-compliance, etc., and achieve the effect of less maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

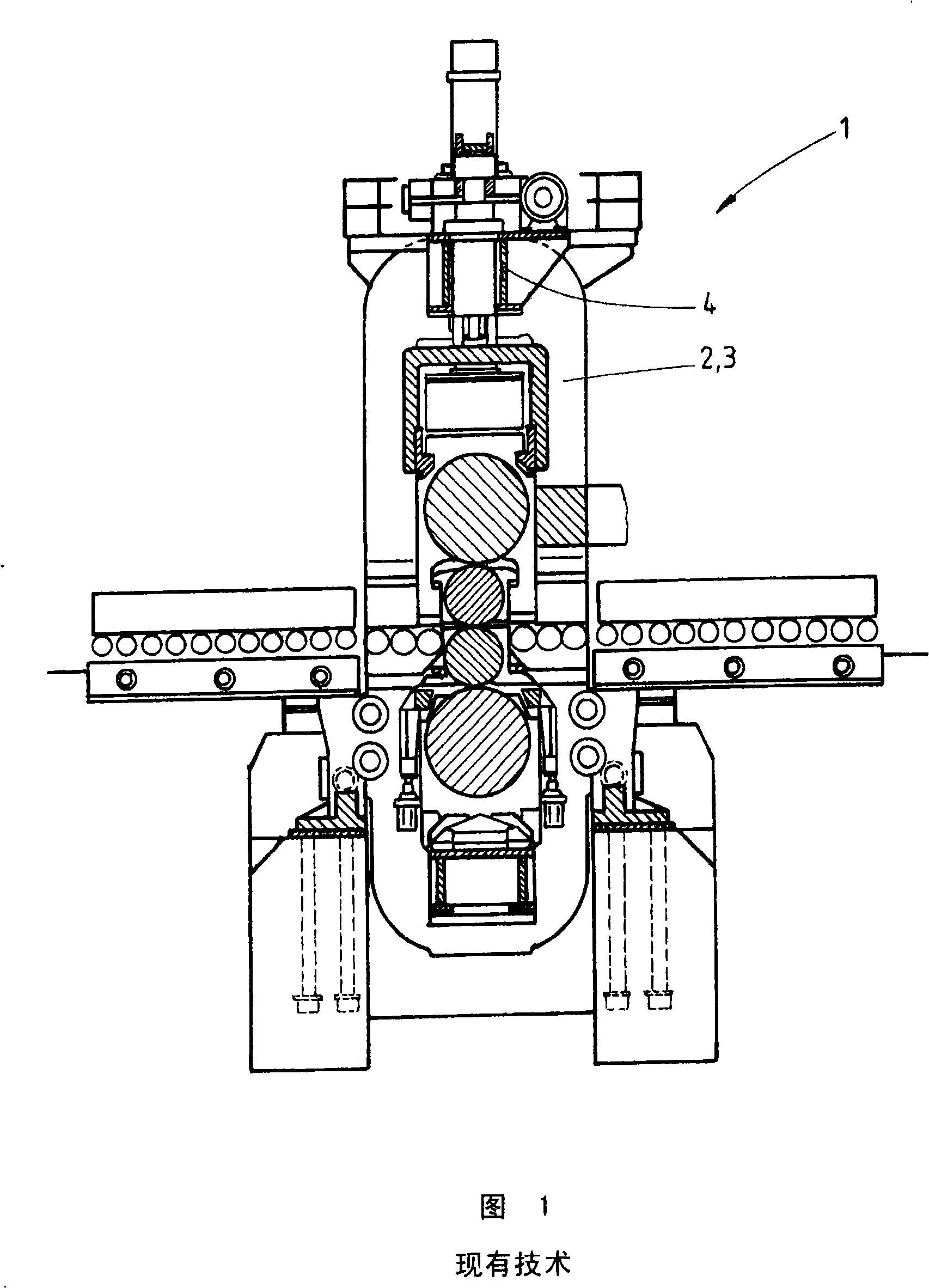

[0035] FIG. 1 shows a partially cut-away side view of a prior art rolling mill stand 1 with stands 2 , 3 and a stand cross member 4 connecting the stands 2 , 3 . Arranged in the frame crossbeam 4 is a backup roller balancing mechanism, the piston rod of which protrudes upwards from the frame crossbeam 4 .

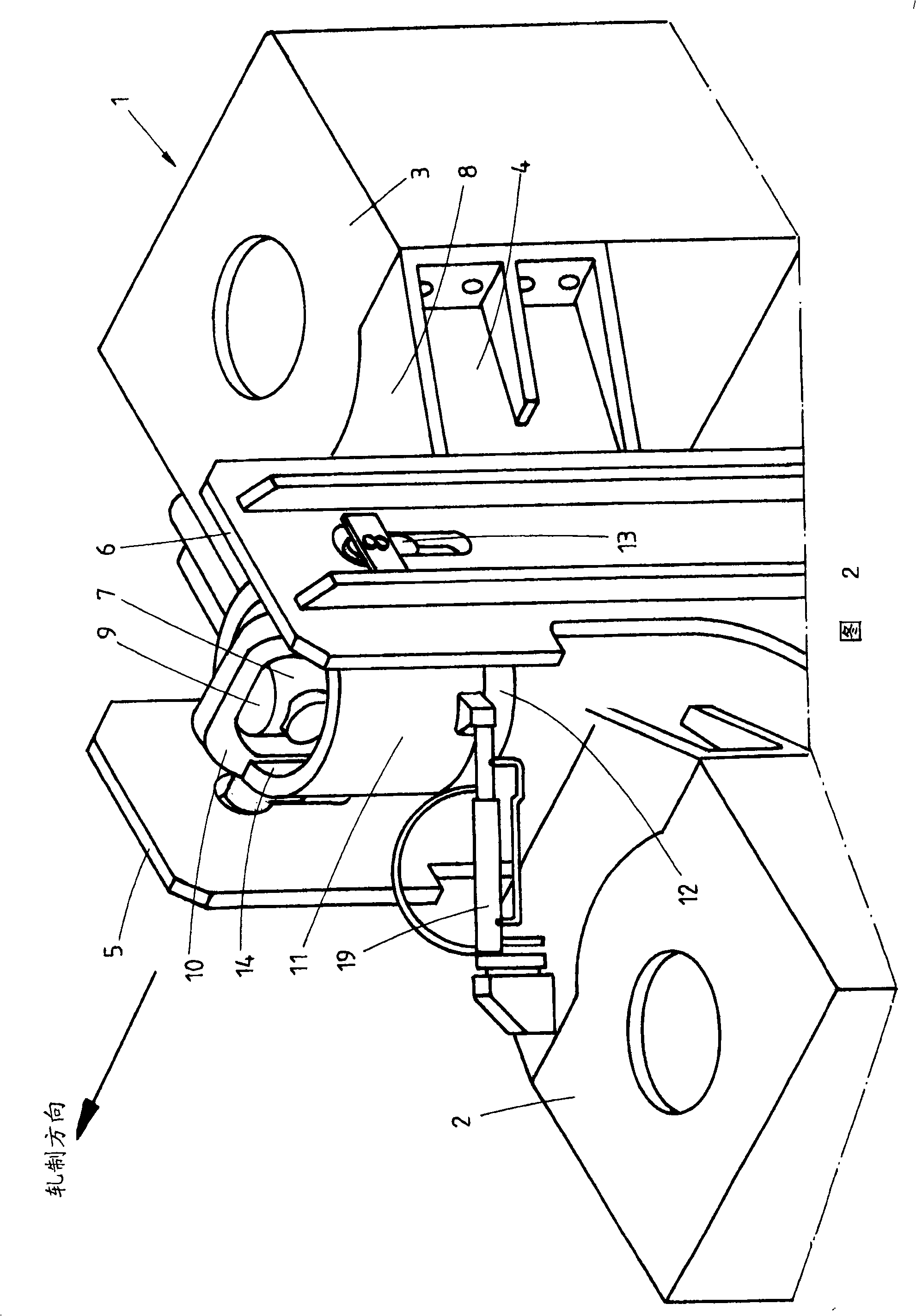

[0036] FIG. 2 shows a schematic three-dimensional view of a rolling stand 1 according to the invention, which has a left stand 2 and a right stand 3 . The two frames are connected to each other at their upper ends by a frame cross member 4 . The piston rod 7 protruding upwards from the frame cross member 4 is slotted at its outer end 9 and receives a yoke 10 . This yoke 10 , which is fastened, for example by pins, to the piston rod 9 is oriented in the rolling direction and engages with its ends in the holding arms 5 , 6 of the compensating mechanism. A rotating sleeve is arranged around said piston rod 7, which is supported on a balancing cylinder 22 of said balancing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com