Design method for reconstructing diversion tunnel into flood discharge tunnel in 'tail-raising' mode

A design method and technology of diversion tunnels, applied in the field of flood discharge tunnels, can solve problems such as high construction technology requirements, high cost, and complex stress, and achieve the effect of easy construction technology, construction technology operation, and simple structure in the tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

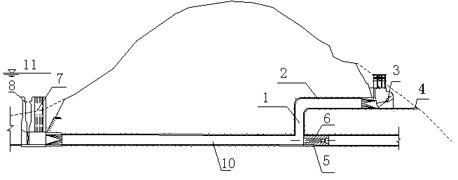

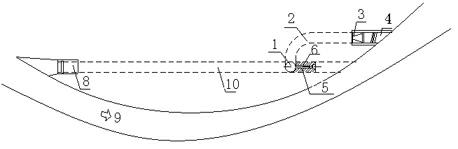

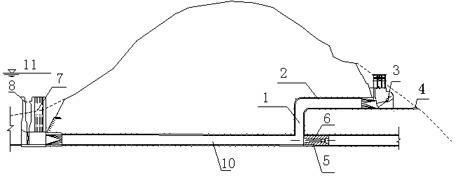

[0023] A flood discharge tunnel converted from a diversion tunnel using the "dragon tail" type, including: a water inlet tower 8, a diversion tunnel 10, a shaft section 1, a horizontal turning section 2, a sluice section 3 and a downstream energy dissipation section 4 The water inlet tower 8 communicates with the front end of the diversion tunnel 10, the diversion tunnel 10 is connected to the vertical shaft section 1 at the end of the joint section, the upper end of the vertical shaft section is connected to the front end of the horizontal turning section 2, and the lower end of the vertical shaft section 1 is connected to the hole of the diversion tunnel 10 The body is connected, and the end of the horizontal turning section 2 is provided with a sluice chamber section 3 and a downstream energy dissipation section 4 .

Embodiment 2

[0025] A flood discharge tunnel converted from a diversion tunnel using the "dragon tail" type, including: a water inlet tower 8, a diversion tunnel 10, a shaft section 1, a horizontal turning section 2, a sluice section 3 and a downstream energy dissipation section 4 The water inlet tower 8 communicates with the front end of the diversion tunnel 10, the diversion tunnel 10 is connected to the vertical shaft section 1 at the end of the joint section, the upper end of the vertical shaft section is connected to the front end of the horizontal turning section 2, and the lower end of the vertical shaft section 1 is connected to the hole of the diversion tunnel 10 The end of the horizontal turning section 2 is provided with a sluice chamber section 3 and a downstream energy dissipation section 4; the end of the diversion tunnel 10 is provided with a blocking section 5; or the water inlet tower 8 is provided with The water inlet 7 in the later stage; or the conical valve 6 is arrange...

Embodiment 3

[0027] Such as figure 1 and figure 2 As shown, a flood discharge tunnel converted from a diversion tunnel using the "dragon tail" type, including: water inlet tower 8, diversion tunnel 10, shaft section 1, horizontal turning section 2, sluice chamber section 3 and downstream extinguishing tunnel The energy section 4, the horizontal turning section 2 and the diversion tunnel 10 are respectively parallel to the horizontal plane. The tail of the diversion tunnel 10 is connected to the shaft section 1, and the lower end of the shaft section 1 communicates with the body of the diversion tunnel 10 to reduce the upstream water level 11 and The water head at the downstream outlet is poor, and the front end of the diversion tunnel 10 is connected with a water inlet tower 8, and the water inlet tower 8 is provided with a later stage water inlet 7, and the later stage water inlet 7 and the water inlet tower 8 are arranged on the upstream of the river 9; The upper end of the shaft secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com