Asphalt cement mortar cart

A cement mortar and asphalt technology, applied in roads, buildings, ballast layers, etc., can solve the problems affecting the construction efficiency of mortar trucks, troublesome operation, heavy workload, etc., and achieve rapid real-time automatic adjustment, convenient installation and debugging, and leveling time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

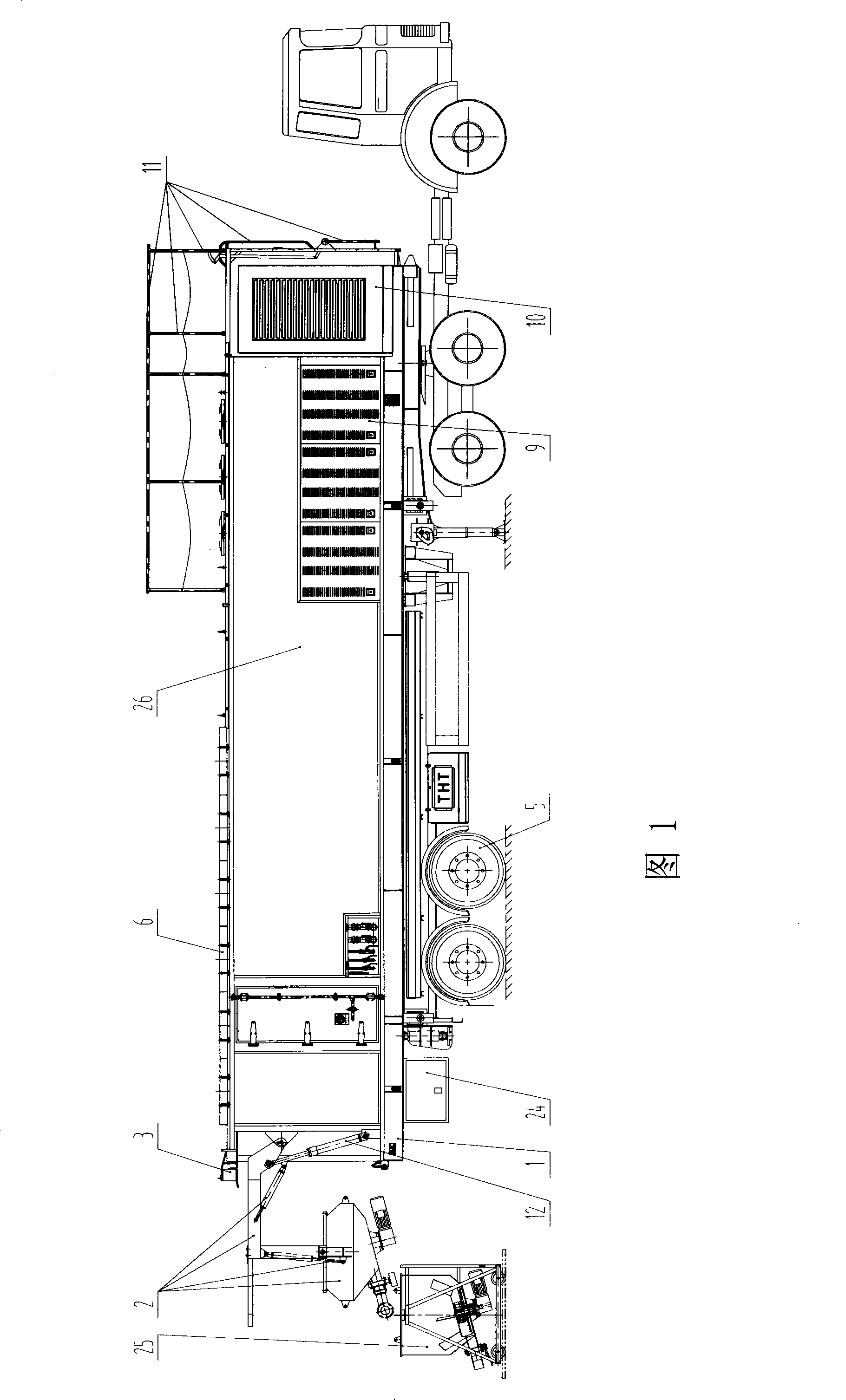

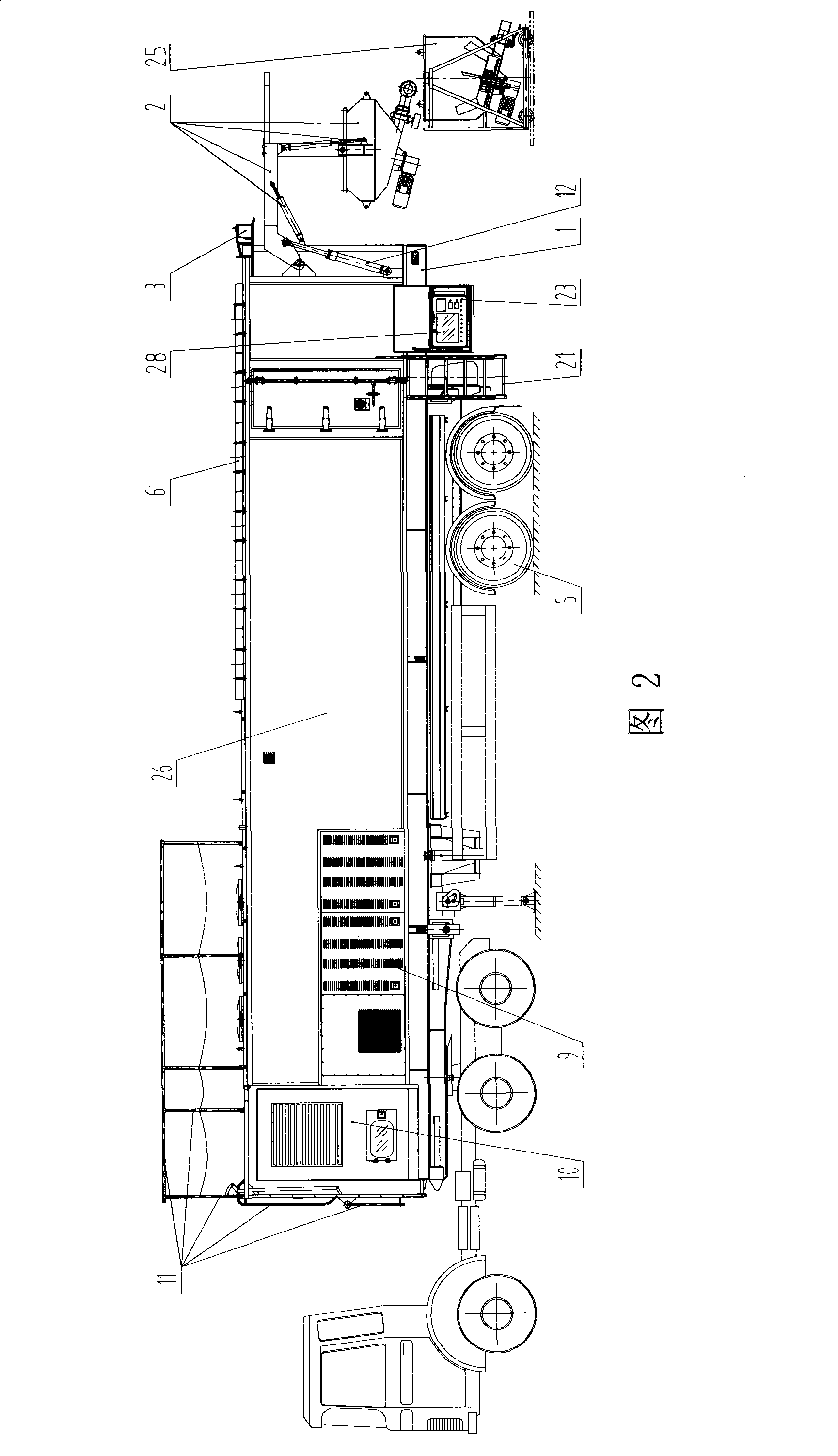

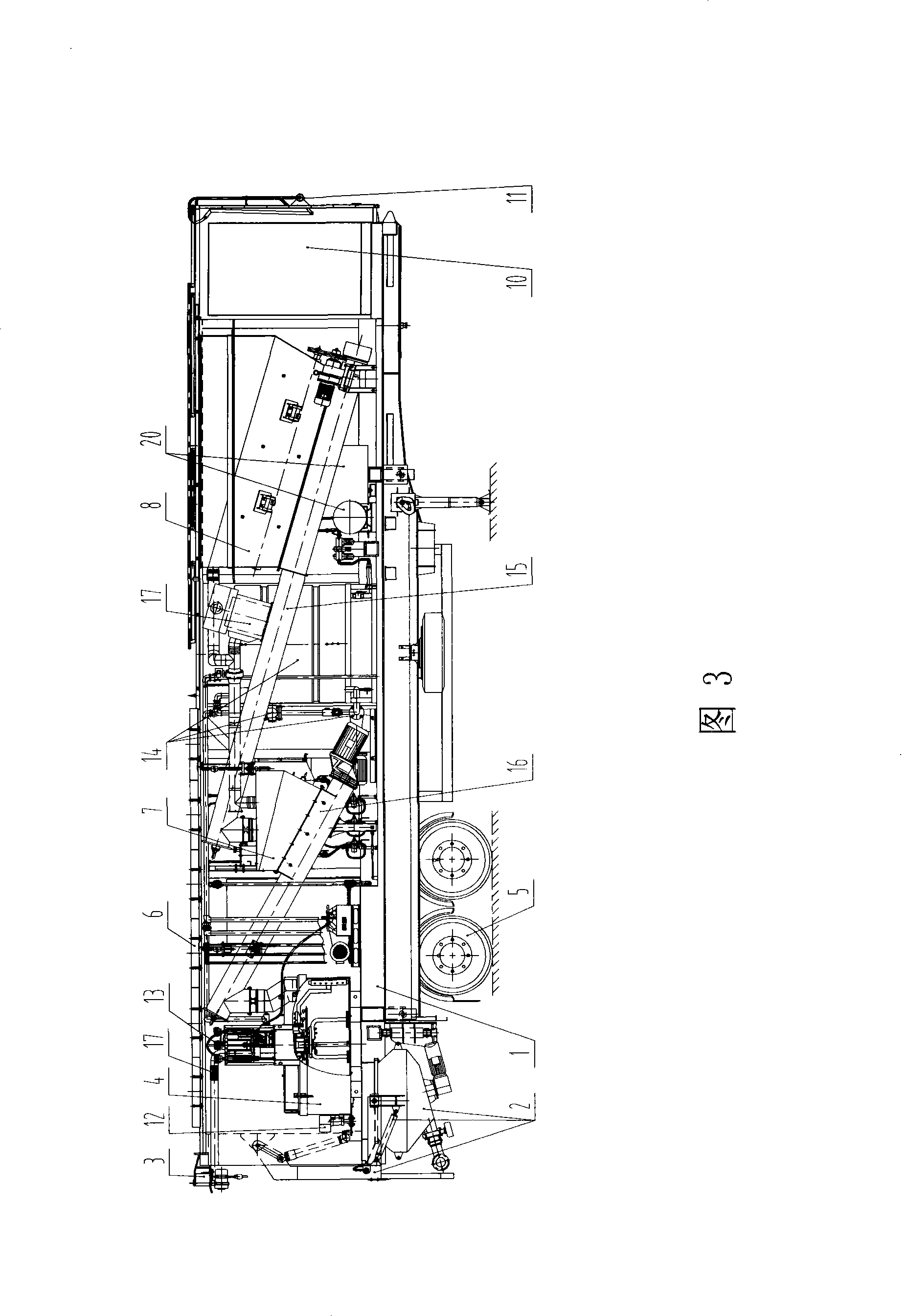

[0082] As shown in Figure 1, Figure 2, Figure 3, Figure 4, Figure 5 and Figure 6As shown, a kind of asphalt cement mortar vehicle of the present invention, it comprises chassis 5 and is installed on chassis 5 top-loading 26, and this top-loading 26 comprises dry powder weighing and feeding assembly, asphalt metering and feeding assembly 14, water metering And feeding assembly 19, admixture metering and feeding assembly 13, mixing host assembly 4, mortar filling assembly, power system, control system and necessary auxiliary systems. Dry powder weighing and feeding assembly, asphalt metering and feeding assembly 14, water metering and feeding assembly 19, admixture metering and feeding assembly 13 are respectively connected to the feeding port end of the mixing main engine assembly 4, and the mixing main engine assembly The discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com