Method for excavating deep foundation pits under temporary bridge of main line railway

A technology for deep foundation pits and bridges, applied in excavation, infrastructure engineering, construction, etc., can solve problems such as inability to meet engineering needs, and achieve the effect of shortening the construction period, reducing the impact of traffic, and meeting construction needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

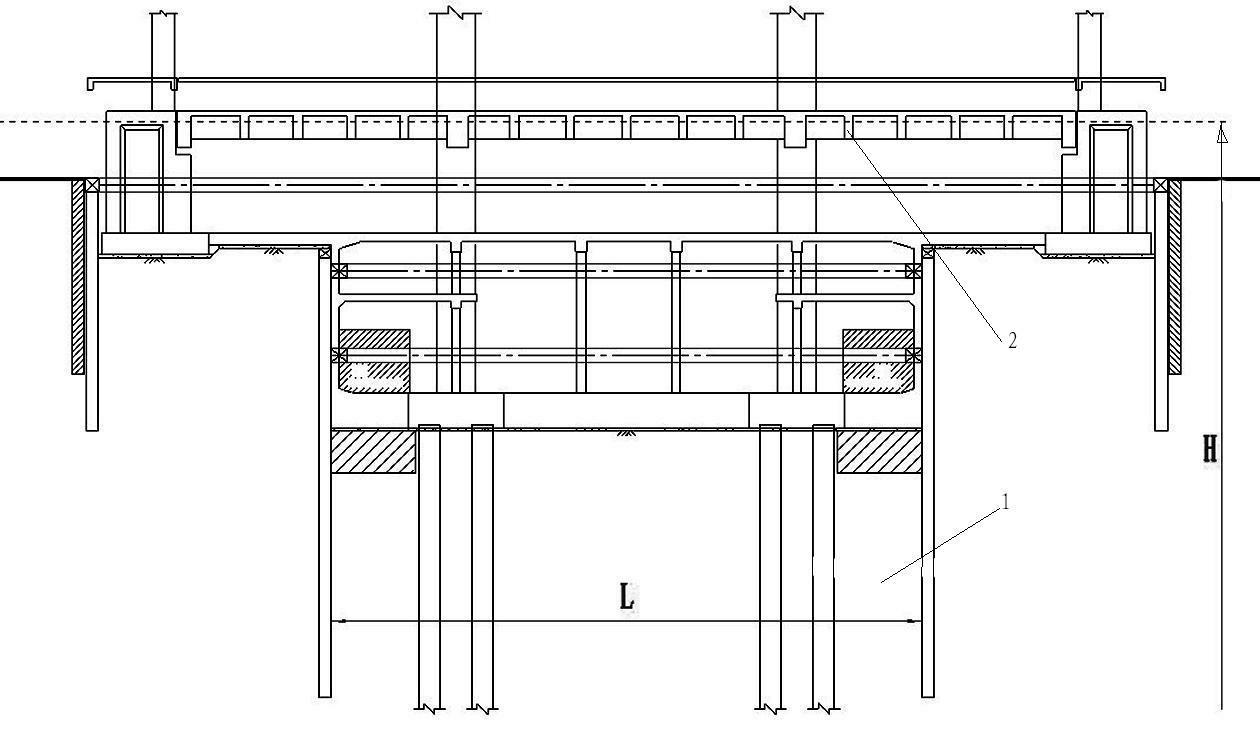

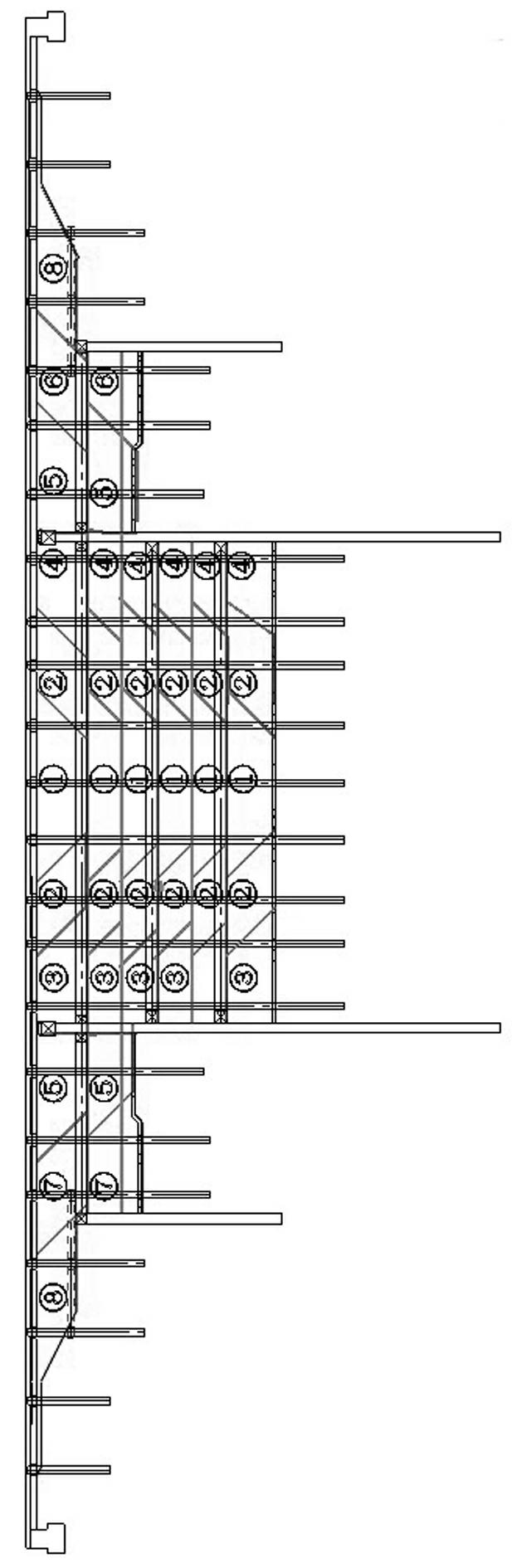

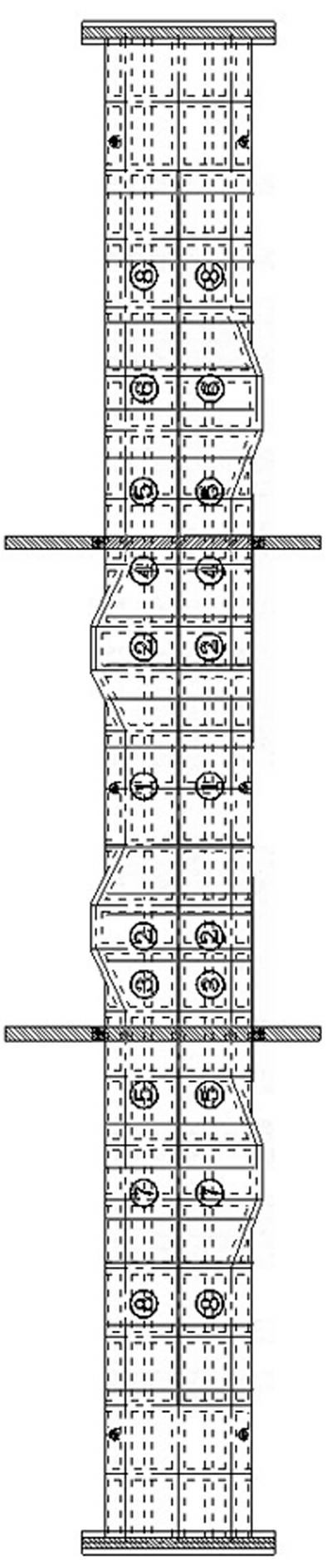

[0018] The specific embodiment of the present invention will be further described in conjunction with accompanying drawing:

[0019] 1. The span of the construction deep foundation pit is 100m, and the depth of the deep foundation pit is 24m.

[0020] The design speed of the train passing the bridge is 80km / h for passenger cars and 45km / h for freight cars. During the excavation, the slow-moving conditions are used to carry out manual excavation, 45km / h for passenger cars and 25km / h for freight cars. The speed of the freight cars is mainly controlled, and there are no passenger cars at night Mechanical excavation is adopted, and the welding operation is carried out within the closed time of the skylight. Since the direct welding of the scissors brace to the lattice column will affect the mechanical characteristics of the column, the perforated ear plate is used in the skylight point to weld firmly with the lattice column at the scissors brace node. , realize the bolting of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com