Spiral submerged-arc welded pipe for oil and gas transmission suitable for low temperatures and manufacturing method thereof

A technology for submerged arc welded pipes and low-temperature environments, which is applied in manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems that low-temperature toughness cannot meet the service requirements of pipelines, and achieve the effect of improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

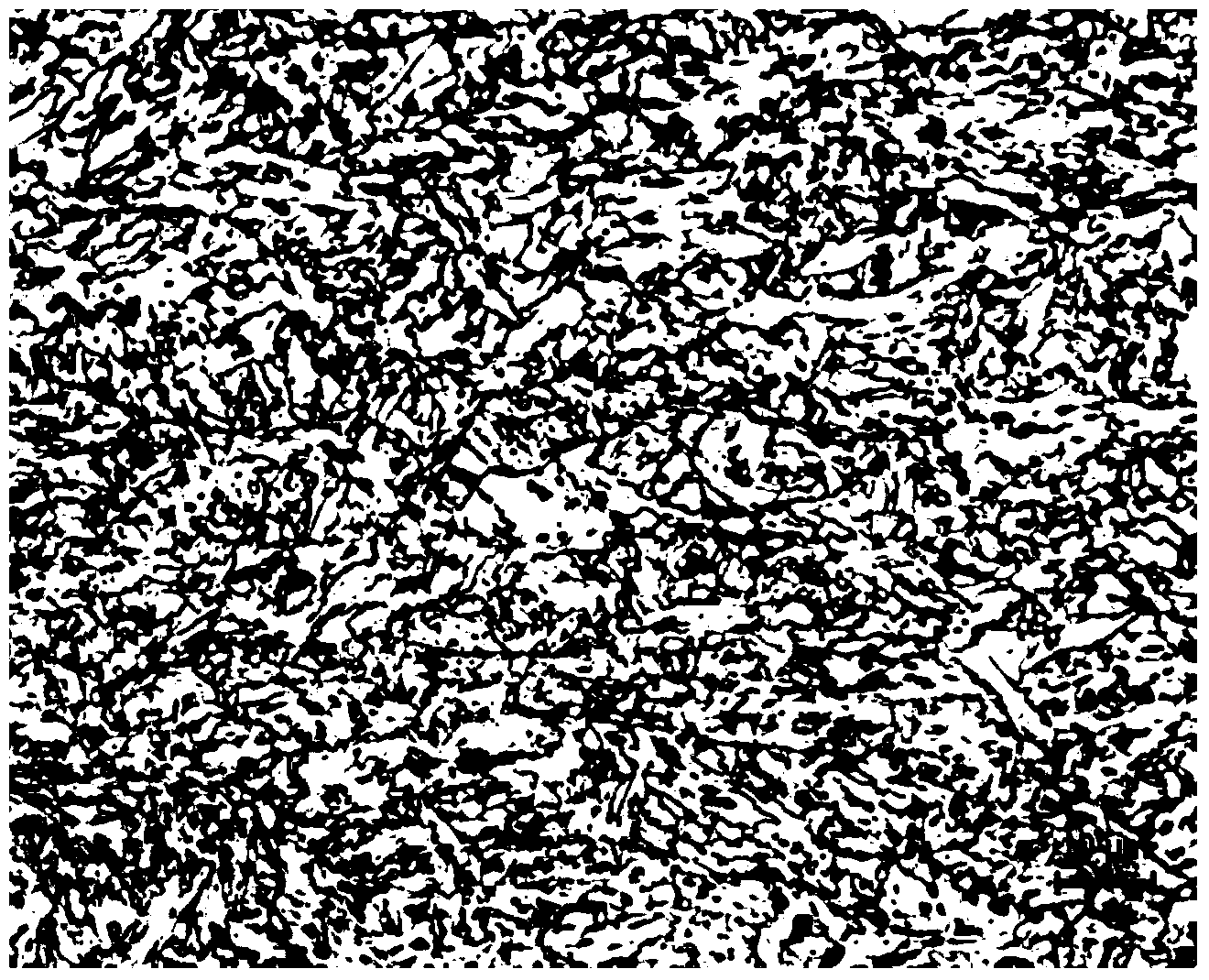

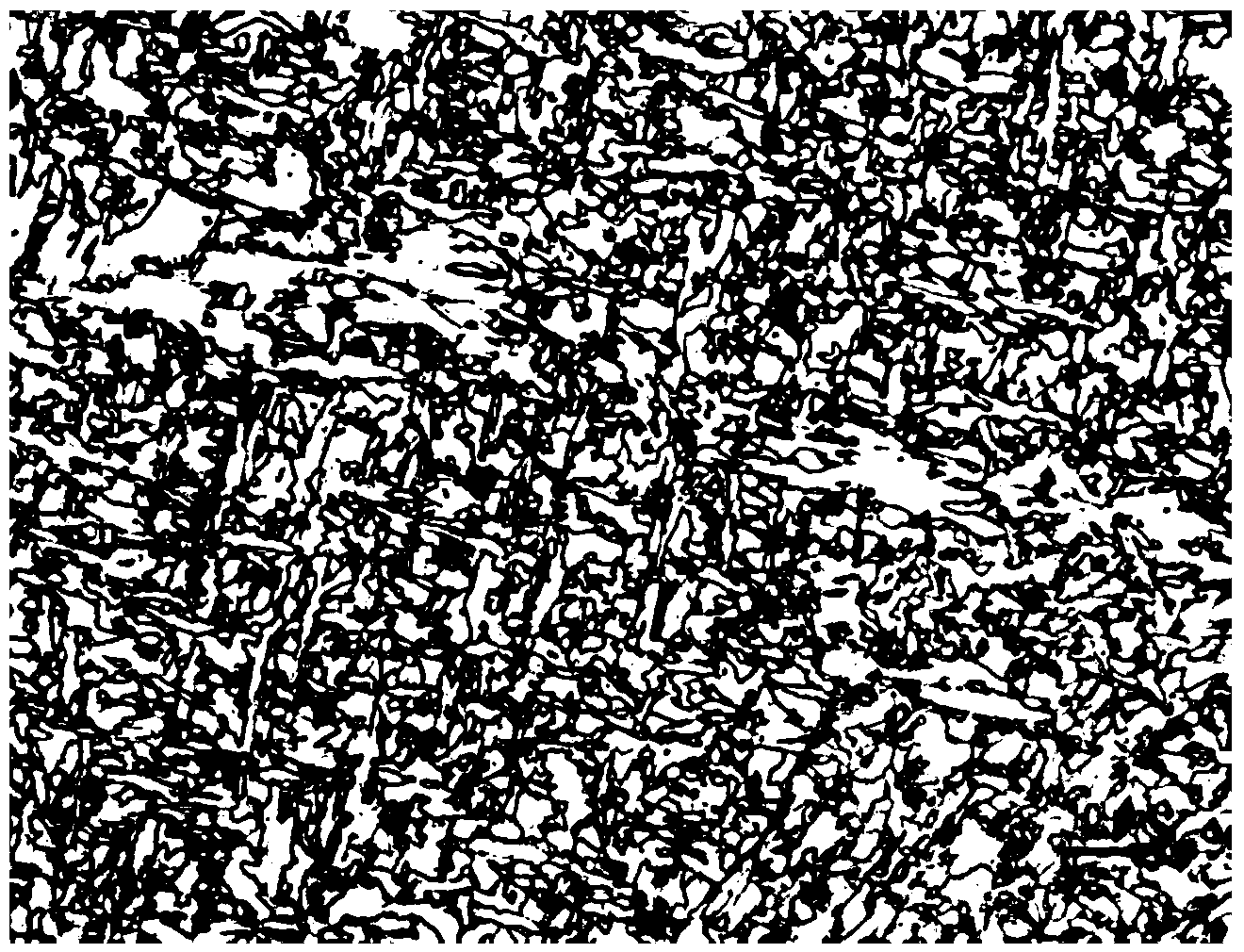

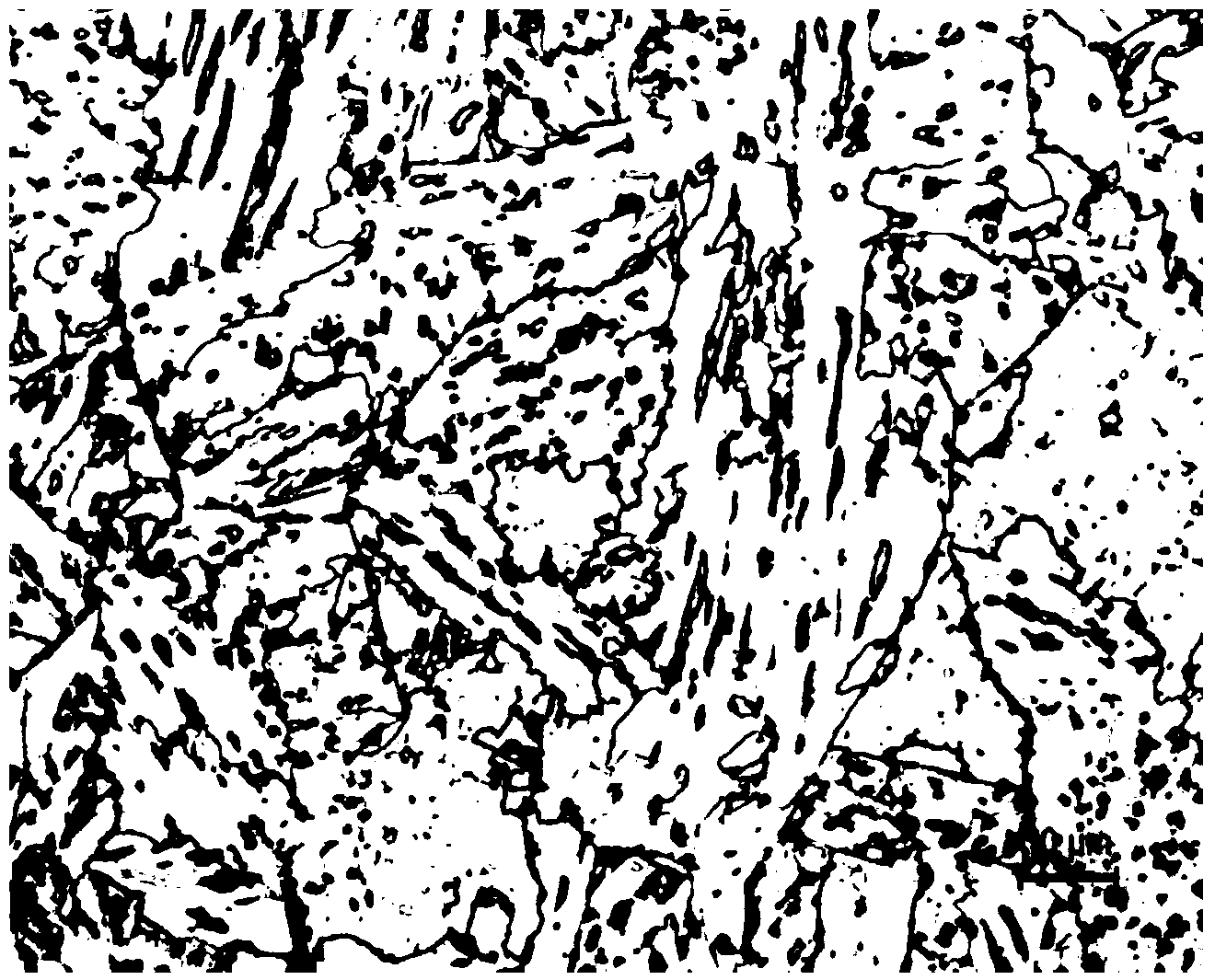

[0031] see figure 1 , figure 2 , image 3 , Pic 4-1 , Figure 4-2 , Figure 5-1 , Figure 5-2 , Figure 6-1 with Figure 6-2 , the present invention obtains a new type of multi-phase structure design based on bainite (such as figure 1 ), achieving excellent low-temperature toughness and good welding processability of the material, so that the toughness of the base metal can be maintained above 100J at -40°C, and the shear area is greater than 85%; the toughness of the heat-affected zone is above 47J at -40°C. At the same time, the present invention also designs a submerged arc welding wire with excellent low-temperature toughness, which can be used with specific sintered flux to ensure that the toughness of the weld seam reaches above 47J at -40°C, which satisfies the requirements of oil and gas in low-temperature and cold environments above -40°C. Toughness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com