Throttle valve

A technology of throttle valve and throttle, applied in the field of throttle valve, can solve problems such as corrosion, and achieve the effect of avoiding unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

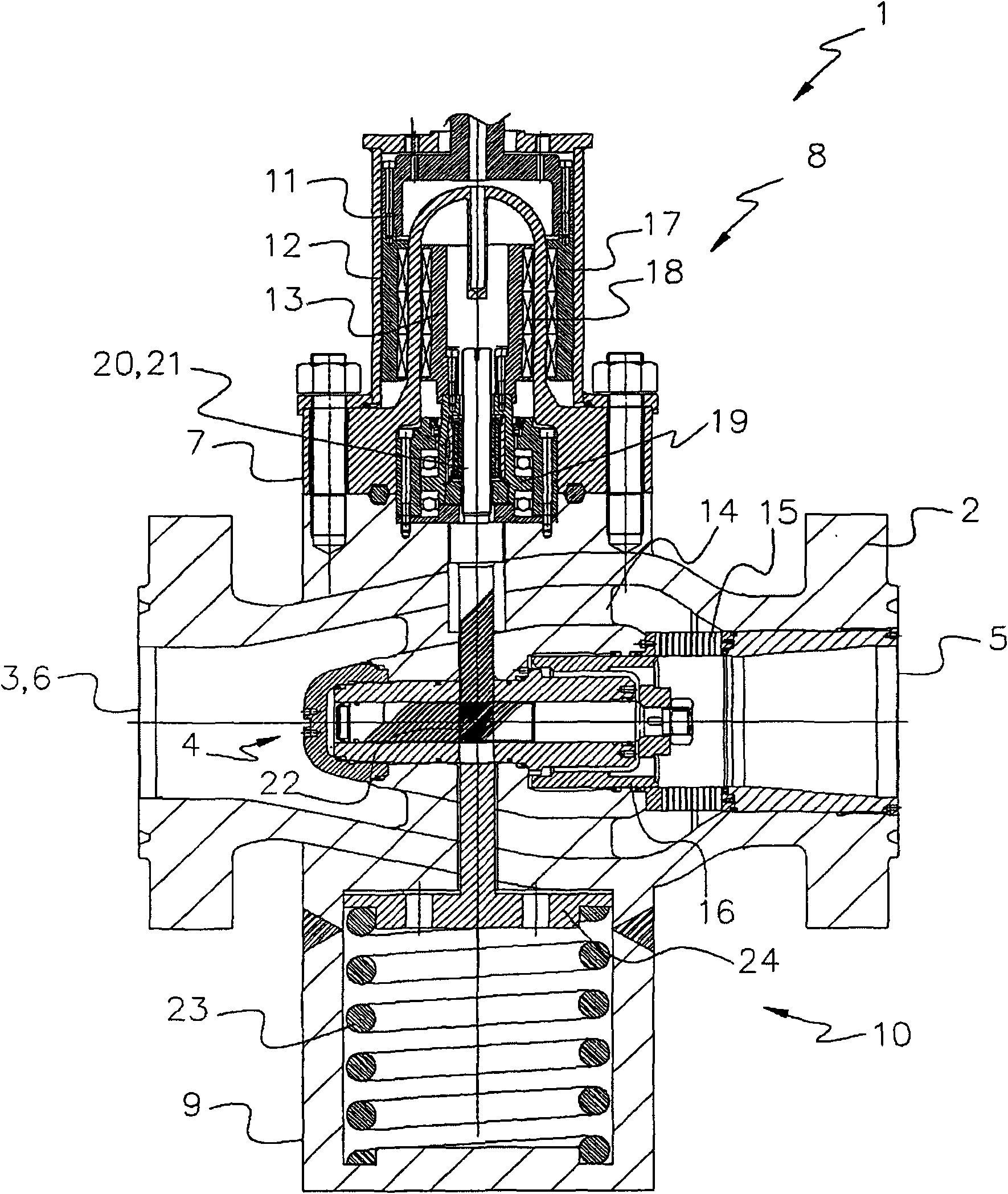

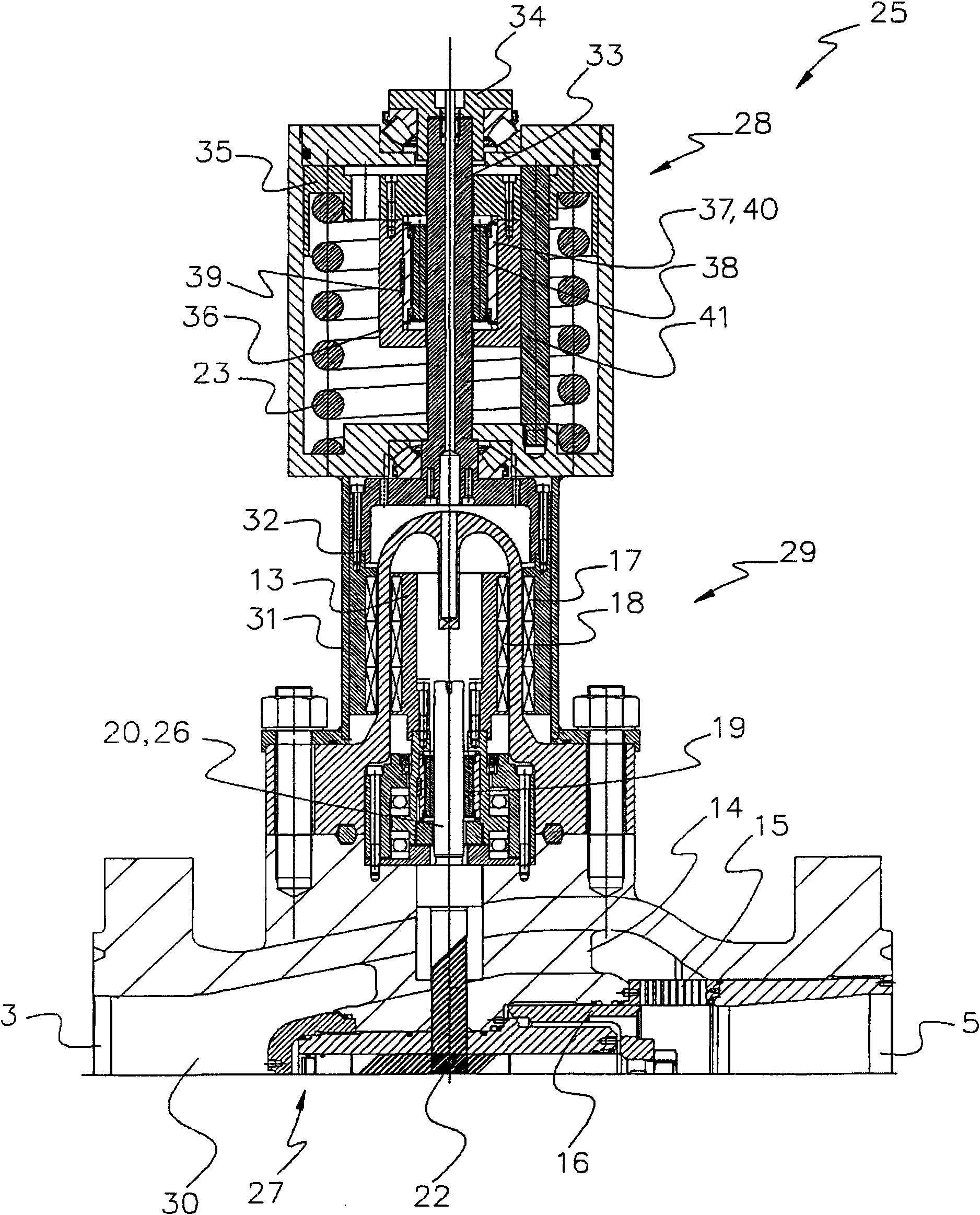

[0031] figure 1The first throttle valve 1 according to the invention shown in has a housing 2 with an inlet 3 for a fluid (not shown) under inflow pressure, with a throttle 4 through which the fluid The flow device 4 can be throttled to the outflow pressure and has an outflow opening 5 for said fluid. The housing 2 consists of a cast valve body 6, a regulating device 8 which is screwed to the housing 7 outside the valve body 6 and a safety device 10 opposite to the regulating device 8 which is also welded on the valve body 6 Upper casing 9 forms.

[0032] The throttle valve 1 has a rotatable adjusting element 11 which is turned upside down in the form of a pot on the adjusting device 8 , which in turn is held by a cup-shaped holder 12 which is screwed to the adjusting device 8 . While substantially the entire housing 2 of the throttle valve 1 is flowed through by fluid, the cage 12 is filled with a pressurized oil compatible with the environment, in particular with sea water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com