Camera sensing assembly and manufacturing method thereof

A manufacturing method and camera-sensing technology, applied to electrical components, electrical solid devices, semiconductor devices, etc., can solve problems such as unfavorable yield rate and reduced yield, and achieve the effects of reducing stress, improving production efficiency, and preventing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

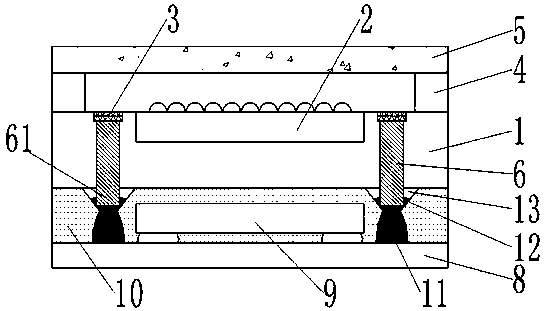

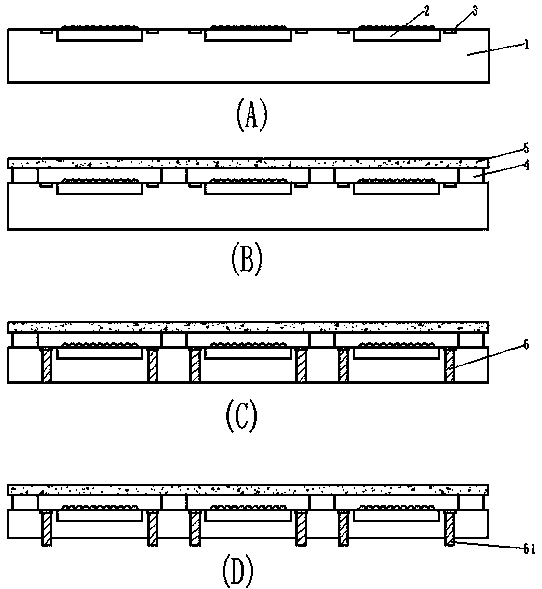

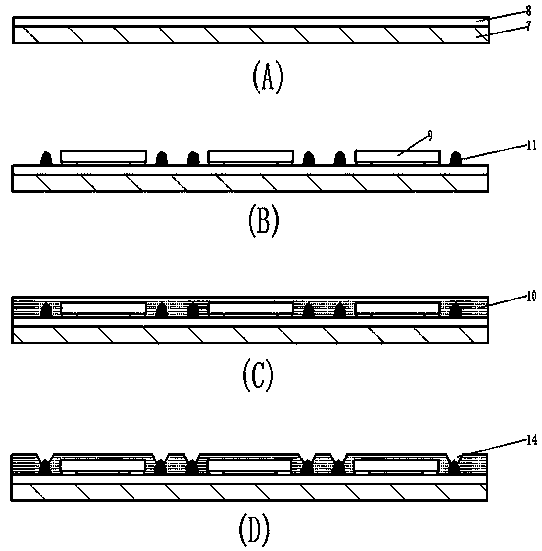

[0032] The idea of the present invention is to design a camera sensing component that can improve yield rate and production efficiency. The basic idea is to use two bonding parts for thermocompression bonding and use an air gap to prevent delamination and peeling problems caused by stress. Specifically Examples will be described in the following.

[0033] see figure 1 , the camera sensing assembly of this embodiment is obtained by bonding a first bonding portion and a second bonding portion, wherein, the first bonding portion, the first bonding portion includes a semiconductor substrate 1, a spacer 4 and cover glass 5. The semiconductor substrate 1 is a traditional silicon material, which is cut from a semiconductor wafer, and has pads 3 and sensor chip regions 2 on its upper surface, and the pads 3 are connected to the sensor chip region 2 .

[0034] The cover glass 5 is adhered on the upper surface of the semiconductor substrate 1 through the spacer 4 . Wherein, the cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com