Underwater bearing platform construction method

A construction method and construction preparation technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of difficult water sealing in the gaps of steel sleeve assembly, increased construction costs, and large steel input, so as to optimize the construction plan, reduce manpower, and construction period. shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

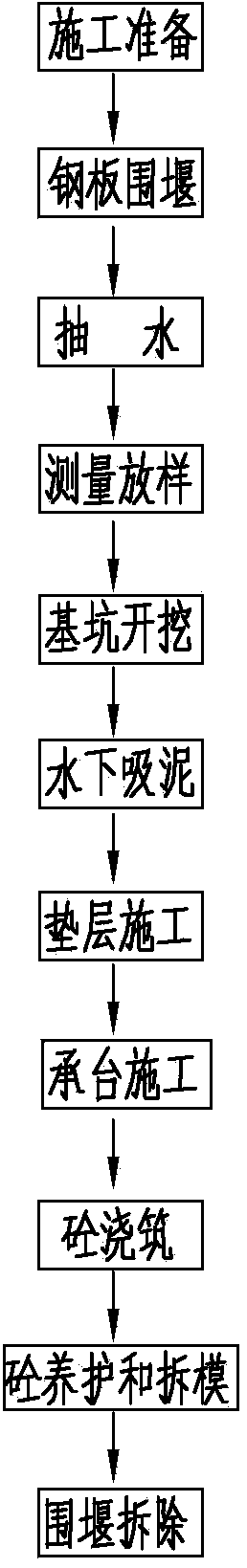

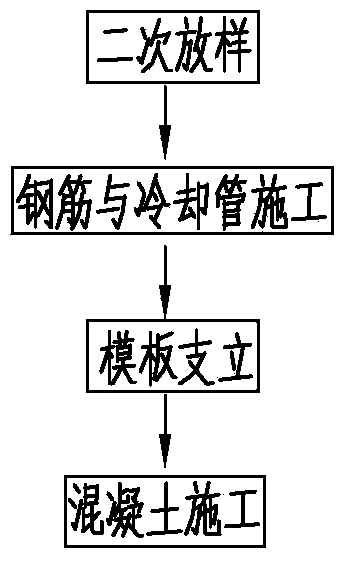

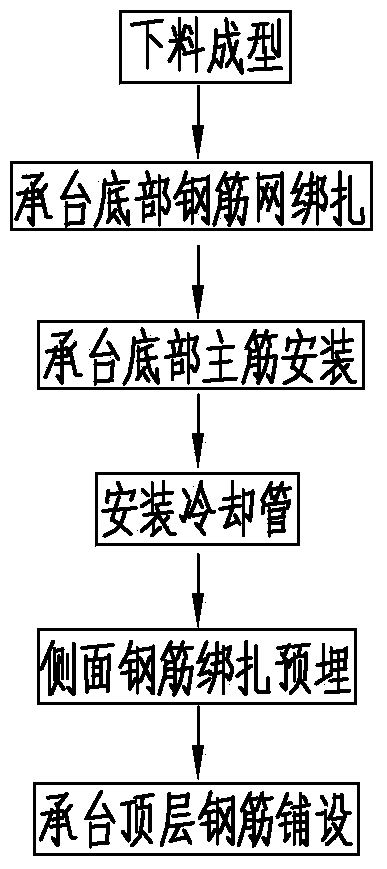

[0036] The invention relates to a construction method of an underwater cap, the technological principle of which is to realize the manufacture and reinforcement of the underwater cap through processes such as measurement and lofting, foundation pit excavation, underwater mud suction, cushion construction, cap construction and the like.

[0037] This construction method requires the following materials:

[0038] 1. C30 concrete (sand and gravel, cement, fly ash, admixture), talcum powder, grade II steel bar, mixed oil.

[0039] 2. Machinery and equipment: concrete transport vehicles, electric welding machines, pump trucks, cranes, vibratory hammers, excavators, ramming machines, air compressors, high-pressure water guns, total stations, levels, water pumps, steel bending machines, pile drivers, water Lower suction dredge, cooling pipe, conduit, storage hopper.

[0040] This construction method includes the following steps (such as Figure 1 to Figure 4 shown):

[0041] (1) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com