Radial and axial roll-forming method for large internal-stage annular piece

A technology of axial rolling and internal steps, applied in the field of machining of large workpieces, can solve problems such as low production efficiency, poor product quality, and low material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

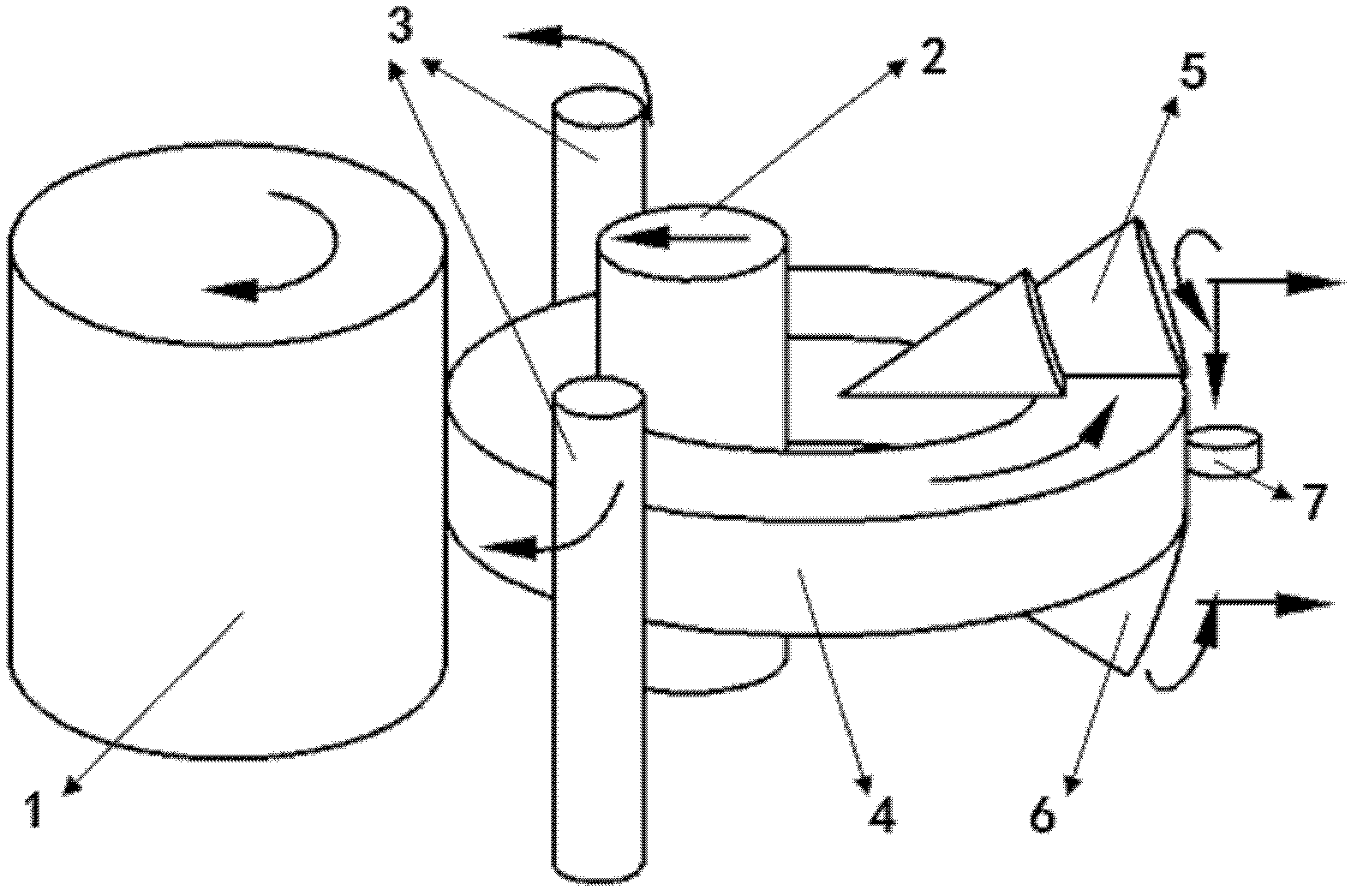

[0073] According to the real-time forming method of the present invention such as figure 1 As shown, the radial and axial ring rolling machine is used to form as figure 2 Large inner step ring piece shown.

[0074] figure 1 The middle ring blank 4 is placed horizontally between the main roll 1 and the core roll 2 of the radial and axial ring rolling machine, and the guide rollers 3 on both sides guide the ring blank 4 from the front and rear directions; the upper tapered roll 5 is a double-layer superimposed cone , process the horizontal upper end face of the ring blank 4; the lower taper roller 6 is single-layer tapered, and process the horizontal lower end face of the ring blank 4; Measurement.

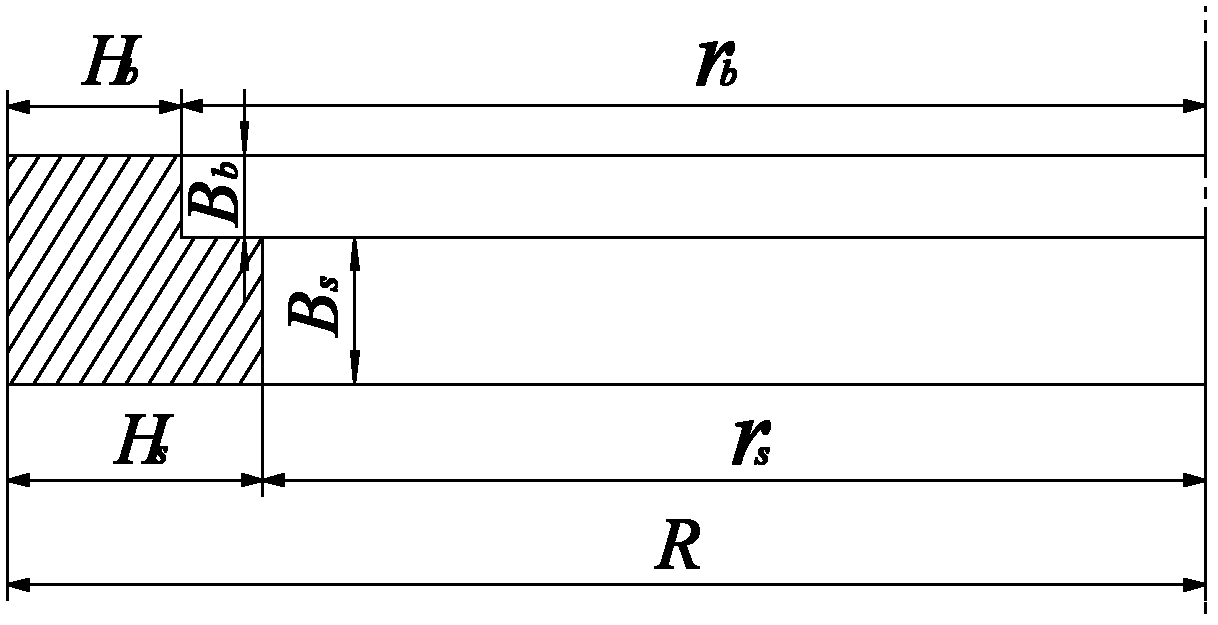

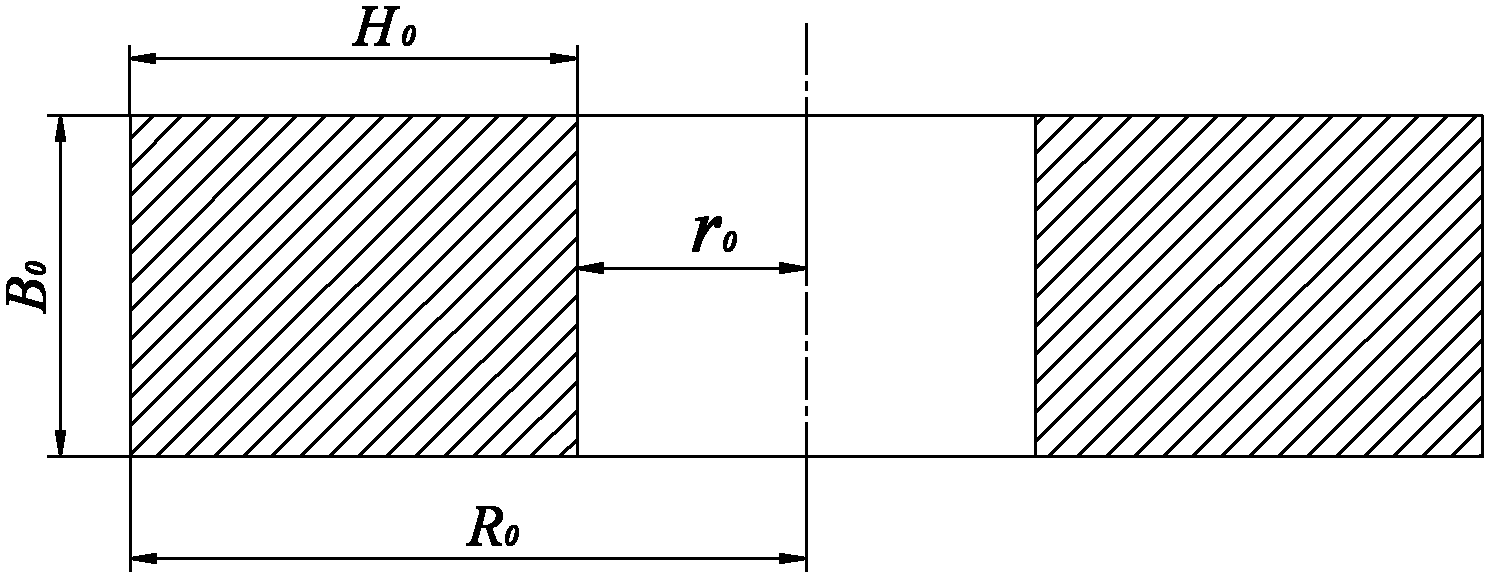

[0075] figure 2 The geometric dimensions of the ring to be formed are as follows: the outer radius R is 2348mm, the radius of the large hole is r b 2008mm, small hole radius r s is 1848mm, the axial height of the big hole B b is 50mm, the axial height of the small hole B s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com