Method for predicting shape and size of CMT welding seam based on ANSYS

A technology of size and welding process, applied in the field of predicting the shape and size of CMT welds based on ANSYS.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] The method for predicting the shape and size of the weld in the Q235 steel plate surfacing process simulation based on ANSYS to predict the CMTQ235 steel plate surfacing process simulation includes the following steps:

[0068] (1) Collect welding process data, including:

[0069] Welding parameters: welding current 234A, welding voltage 21V, wire feeding speed 10.0m / min, welding speed 16.7mm / s

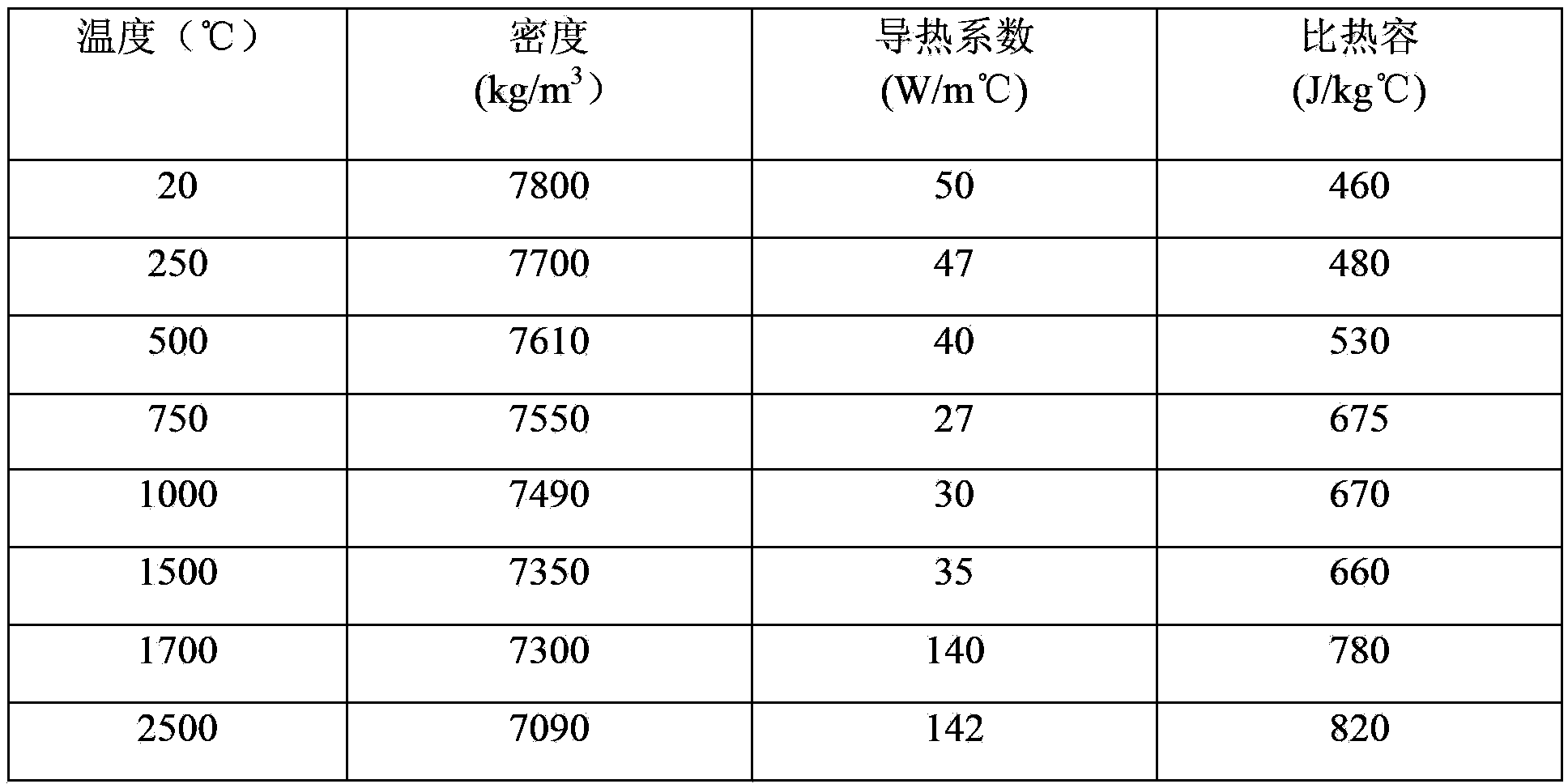

[0070] Material thermophysical parameters: thermal conductivity, specific heat, density (such as figure 2 shown);

[0071] Initial information: weldment size 200mm×50mm×3mm, ambient temperature 20°C;

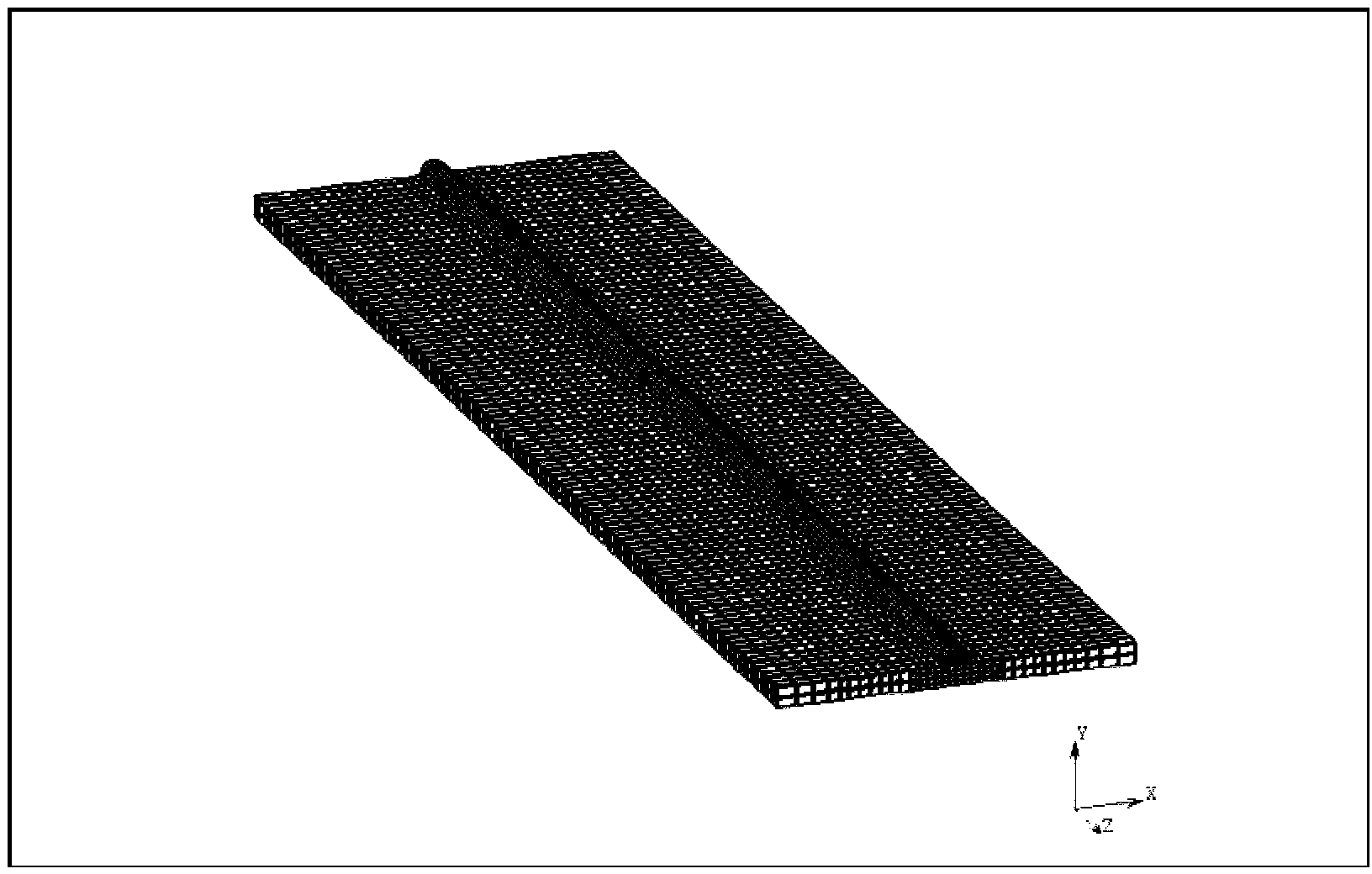

[0072] (2) Establish finite element analysis model

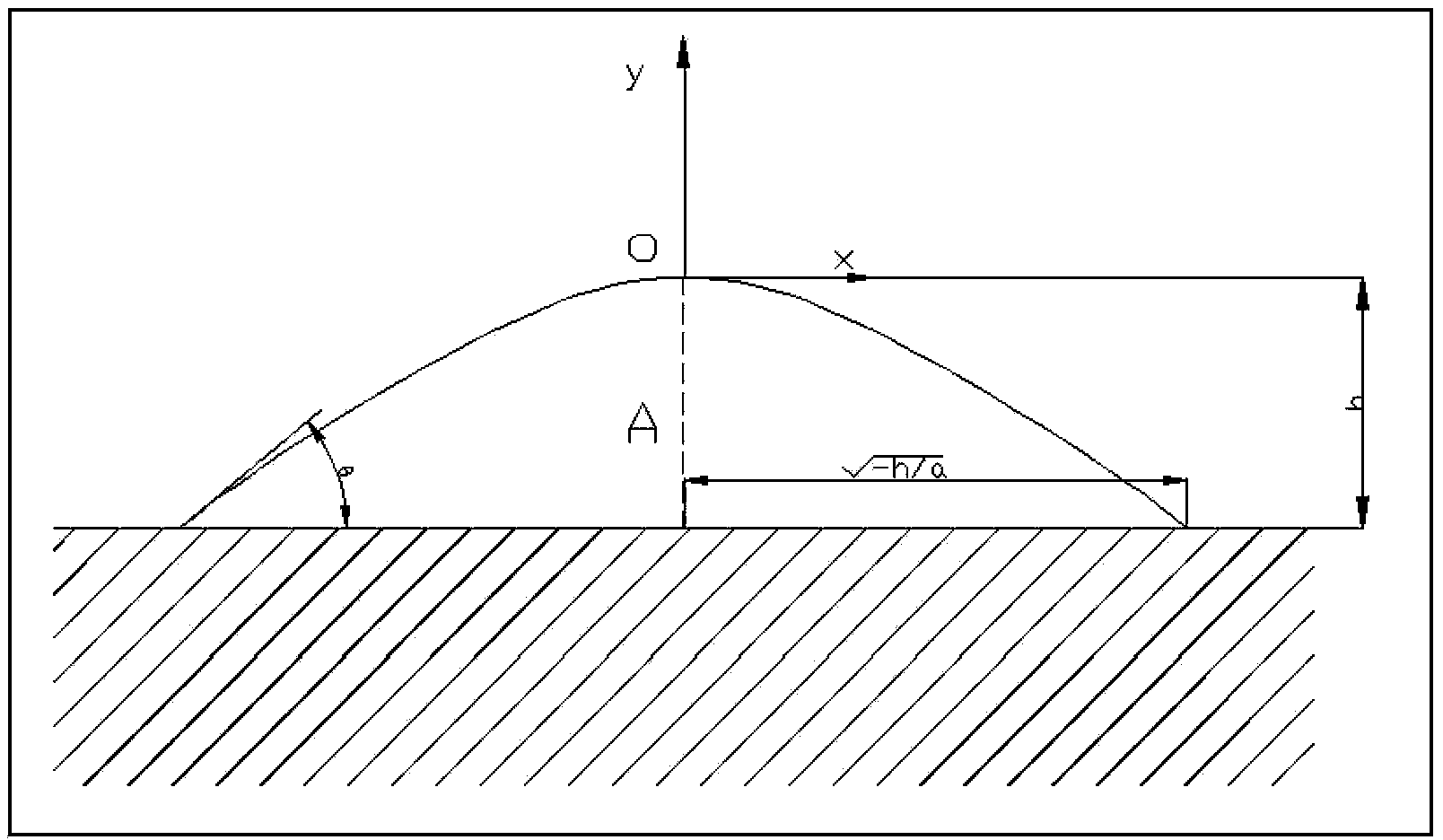

[0073] Processing of weld reinforcement: In finite element analysis, the weld reinforcement is added to the workpiece in advance, and the element activation method is used in the calculation process to process it; in order to simplify the calculation, the cross-sectional contour curve of the reinforcement is set as: y =ax ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com