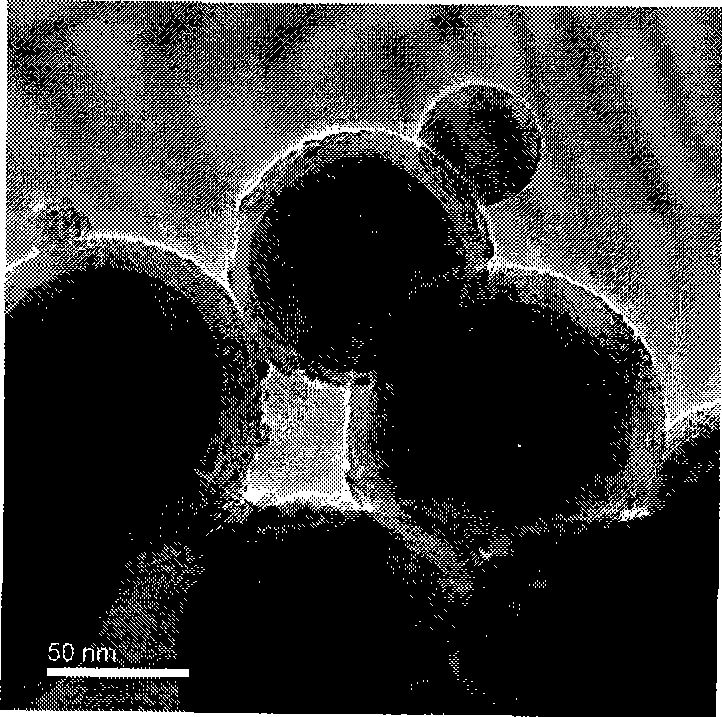

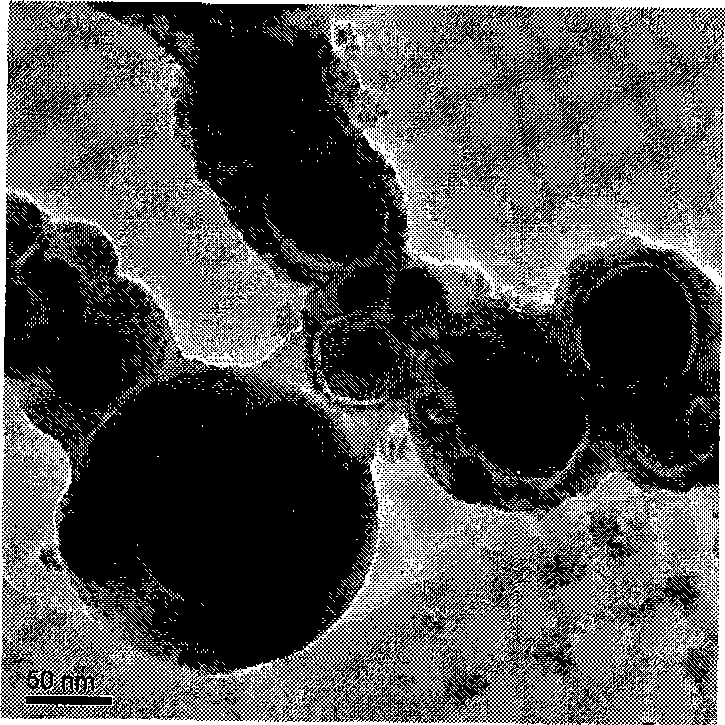

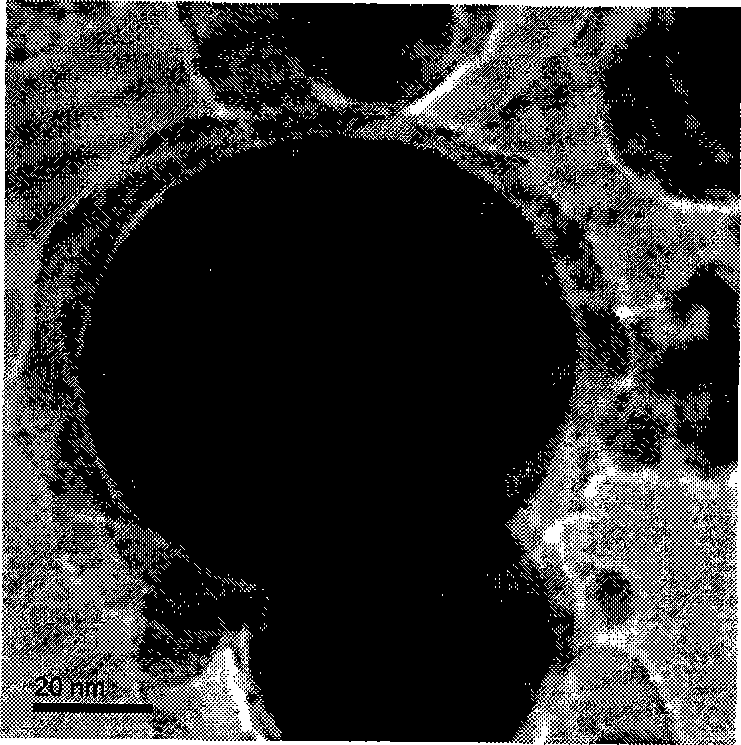

Synthesis method of metallic oxide coated dissimilar metal 'core/shell'nano-particles

A technology of heterogeneous metals and oxides, applied in the direction of coating, etc., can solve the problems of high cost, complicated process, environmental pollution, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The raw materials of nickel micron powder and alumina micron powder are uniformly mixed according to the mass ratio of 5:1, and pressed into blocks. The mixed sample block was used as the anode, and the tungsten electrode was used as the cathode. Evacuate the reaction chamber to a vacuum of 10 -3 About Torr, 350 Torr of hydrogen and 350 Torr of argon are introduced, and the discharge evaporation is carried out in the DC arc plasma device. The discharge current is 150-200 amperes; the voltage is 20-40 volts. After the reaction is over, after the floating powder is deposited on the wall of the reaction chamber, the hydrogen and argon are pumped out to 10 -1~1.0 Torr, let stand for 6~12 hours to complete passivation. A large amount of black powder is deposited on the inner wall of the reaction chamber, and the powder is collected.

Embodiment 2

[0037] The raw materials of iron micron powder and manganese oxide micron powder are uniformly mixed according to the mass ratio of 5:1, and pressed into blocks. The mixed sample block was used as the anode, and the tungsten electrode was used as the cathode. Evacuate the reaction chamber to a vacuum of 10 -3 About Torr, 350 Torr of hydrogen and 350 Torr of argon are introduced, and the discharge evaporation is carried out in the DC arc plasma device. The discharge current is 150-200 amperes; the voltage is 20-40 volts. After the reaction is over, after the floating powder is deposited on the wall of the reaction chamber, the hydrogen and argon are pumped out to 10 -1 ~1.0 Torr, let stand for 6-12 hours to complete passivation. A large amount of black powder is deposited on the inner wall of the reaction chamber, and the powder is collected.

Embodiment 3

[0039] The raw materials of nickel micron powder and titanium oxide micron powder are uniformly mixed according to the mass ratio of 5:1, and pressed into blocks. The mixed sample block was used as the anode, and the tungsten electrode was used as the cathode. Evacuate the reaction chamber to a vacuum of 10 -3 About Torr, 350 Torr of hydrogen and 350 Torr of argon are introduced, and the discharge evaporation is carried out in the DC arc plasma device. The discharge current is 150-200 amperes; the voltage is 20-40 volts. After the reaction is over, after the floating powder is deposited on the wall of the reaction chamber, the hydrogen and argon are pumped out to 10 -1 ~1.0 Torr, let stand for 6~12 hours to complete passivation. A large amount of black powder is deposited on the inner wall of the reaction chamber, and the powder is collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com