Wire-width-variable laser galvanometer scanning quick etching method and device

A laser galvanometer and laser etching technology, which is applied to laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems that the laser power density should not be too large and damage the substrate material, so as to ensure the edge etching accuracy and reduce the Power density gradient, effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

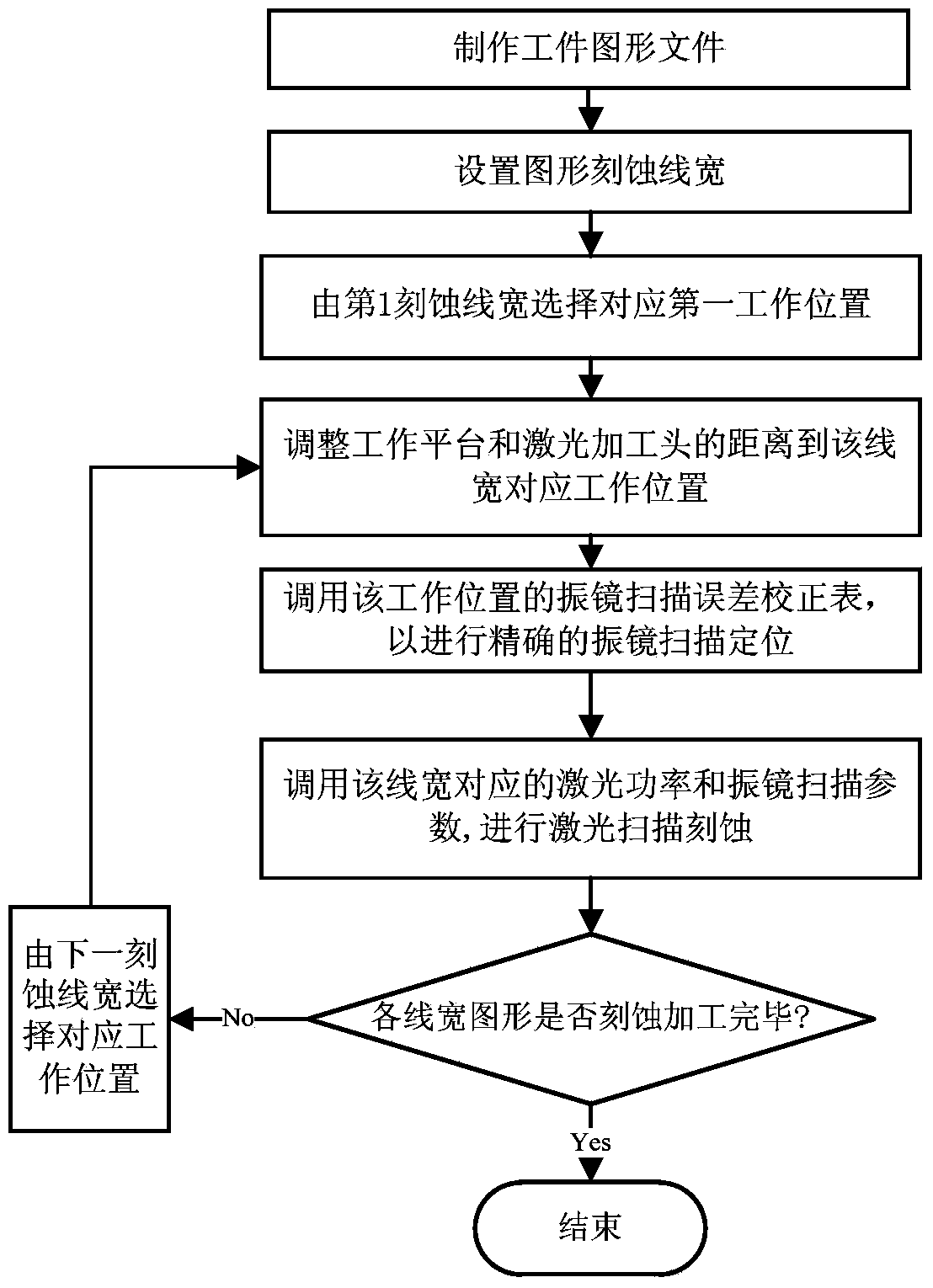

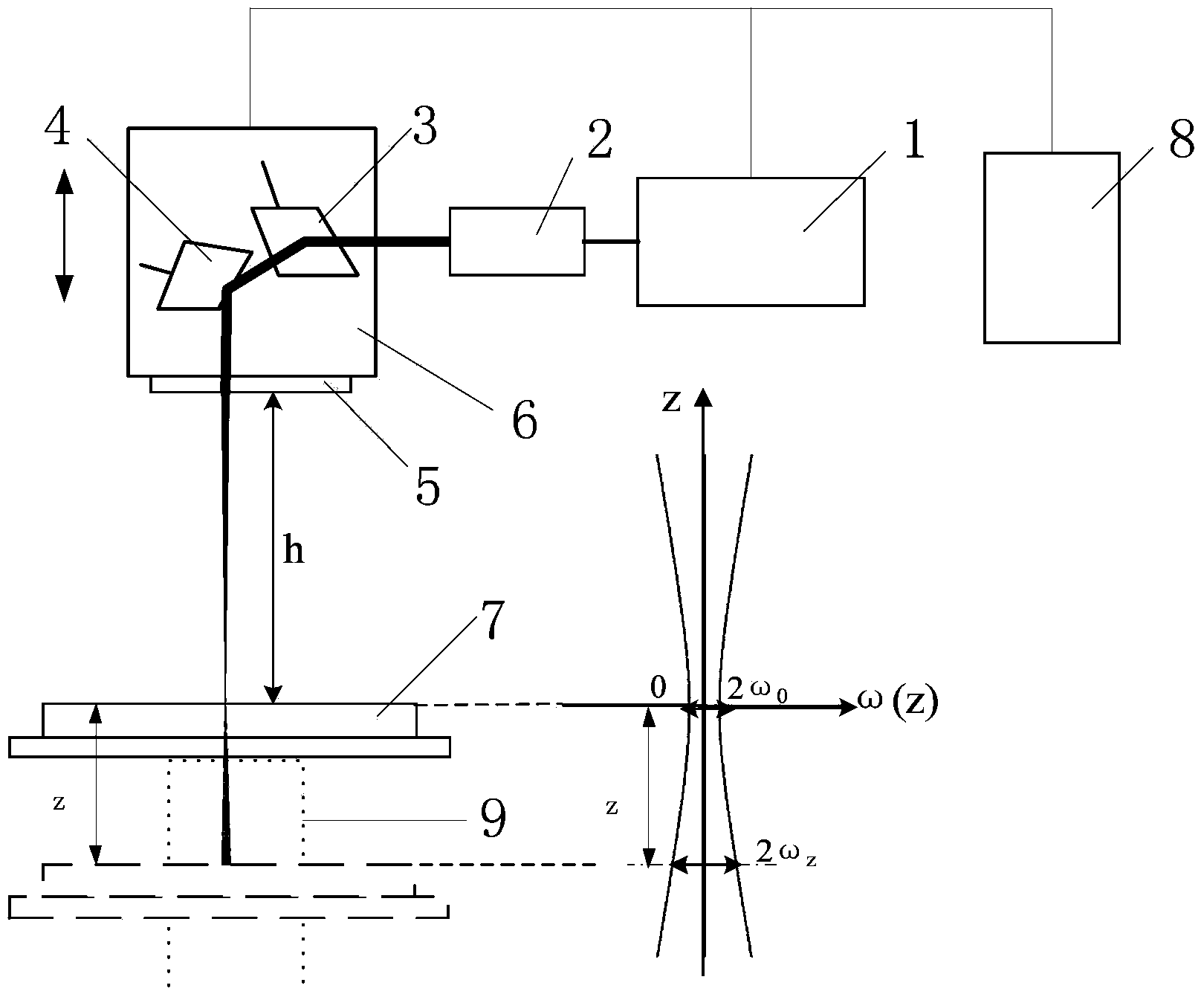

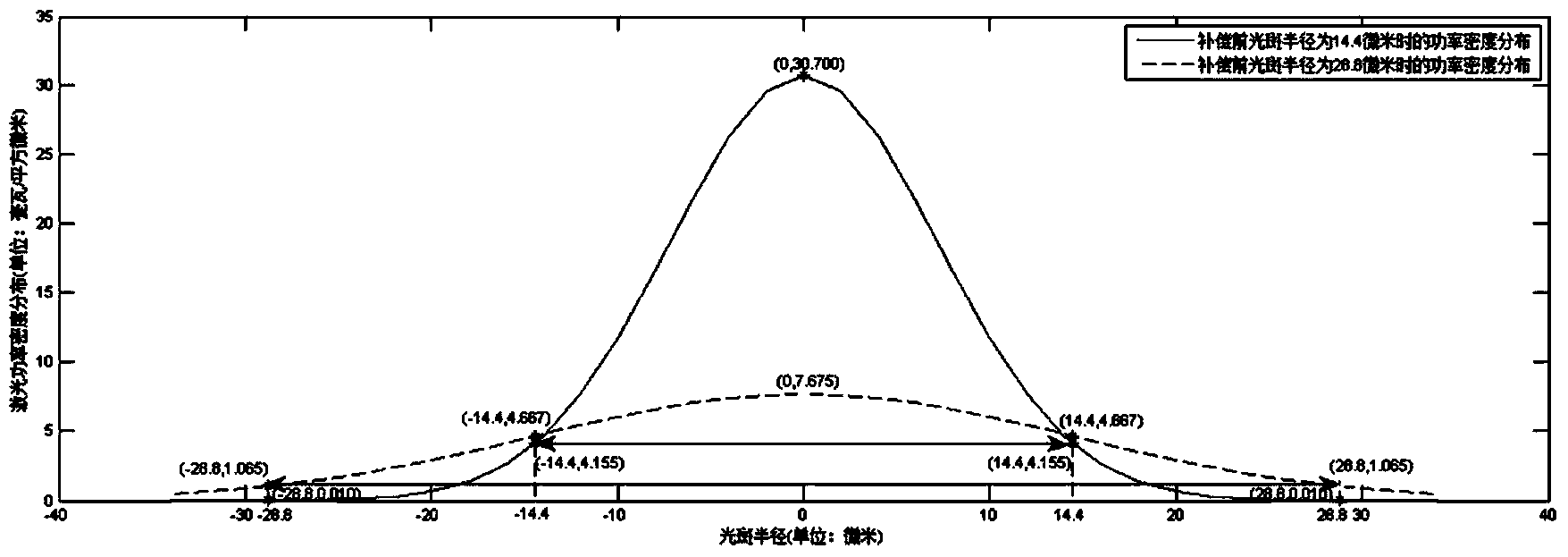

[0030] The invention utilizes the principle that the power density gradient becomes smaller and the spot becomes larger after the laser beam is defocused and the high-speed galvanometer scanning error accurate correction method is used to fill the graphic filling area with a large spot raster scan after defocusing, and then vector scan the graphic outline outline. The present invention controls the laser spot size by setting different in-focus and defocus laser processing distances and corresponding power parameters and laser galvanometer scanning parameters, and compensates the total power of the large-size laser spot after defocus through theoretical calculation and experimental testing, so as to Ensure that the laser energy density of the large out-of-focus spot meets the material etching threshold.

[0031] The present invention utilizes the high-speed advantages of the galvanometer scanning technology, corrects the galvanometer scanning error in advance for different work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com