Battery managing system testing platform

A technology for battery pack management and system testing, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables. It can solve the problems of time and energy consumption, high testing cost, and inconvenient testing, and achieve convenient testing, simple structure, and high precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

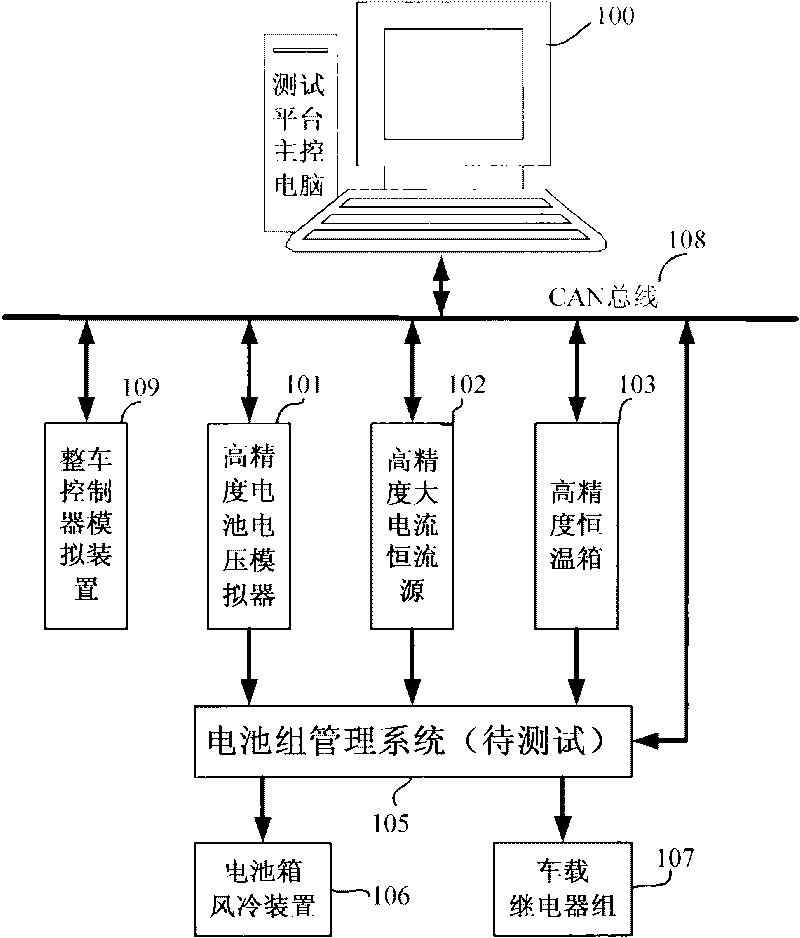

[0069] Embodiment 1. Simulation test of lithium-ion BMS for pure electric cars.

[0070] The simulation test of lithium-ion BMS for pure electric cars mainly includes battery pack data sampling accuracy test, SOC estimation accuracy test, and common battery pack fault test.

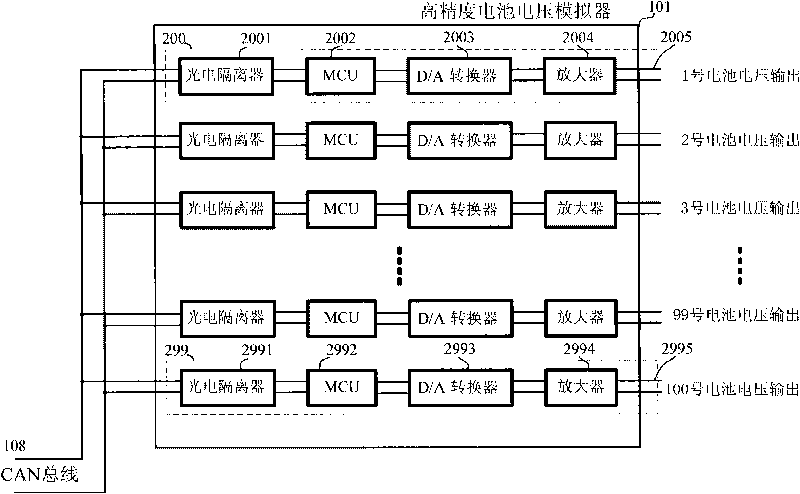

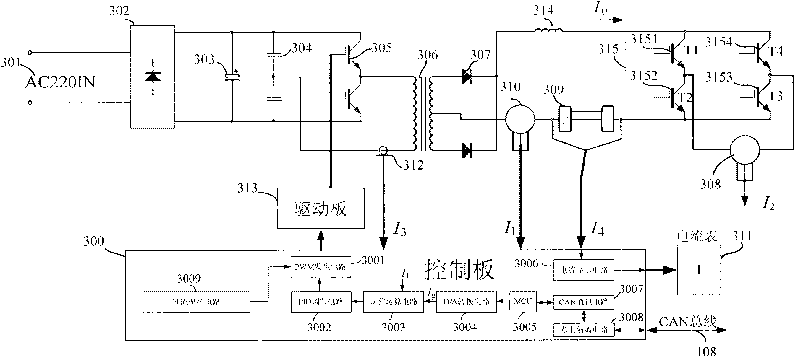

[0071] The process of battery pack data sampling accuracy test is as follows: Figure 7 shown. The main control computer of the test platform outputs the battery pack characteristic data through the CAN bus according to the user's settings, including the battery pack's single cell voltage setting data, charging and discharging current setting data and battery pack temperature setting data. At the same time, the above battery pack characteristic data is also output to the battery pack data acquisition and analysis software for comparison and analysis with the BMS sampling data. After receiving the single battery voltage setting data, the high-precision battery voltage simulator converts the data into the...

Embodiment 2

[0078] Embodiment 2, the simulation test method of the nickel-metal hydride power battery pack controller used in the hybrid electric vehicle.

[0079] Another embodiment of the present invention is used to test a power battery pack management system. The BMS is used to manage nickel-metal hydride power batteries, and the BMS and the nickel-hydrogen power battery pack are used together for hybrid electric vehicles.

[0080] Hybrid electric vehicle Ni-MH power battery pack is generally composed of 120 to 280 single cells, the total voltage range is 100 to 500V, and the working voltage range of each single cell is 0.7 to 1.65V. Generally, 5 to 10 battery cells are connected in series to form a battery pack module, and then the modules are connected in series to form the entire power battery pack.

[0081] The BMS test platform simulates the Ni-MH power battery pack through the following method: Calculate the voltage range of the module battery according to the number of single c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com