Method for confirming anisotropism of jointed rock mass

A jointed rock mass, anisotropic technology, applied in the direction of using stable shear force to test material strength, using stable tension/pressure test material strength, instruments, etc., can solve problems such as complex theoretical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

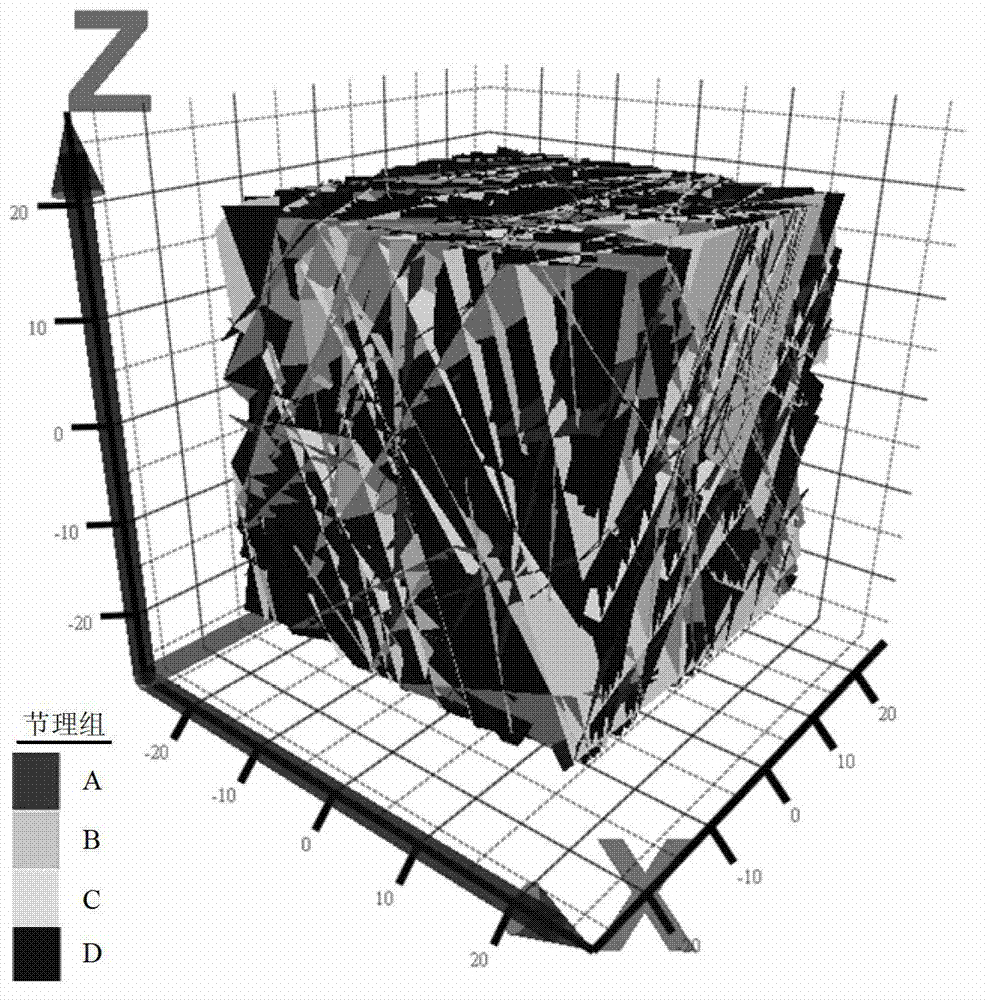

[0027] Taking a high rock slope of an open-pit iron mine as an example, a method for determining the anisotropy of jointed rock mass is introduced, which includes the following steps:

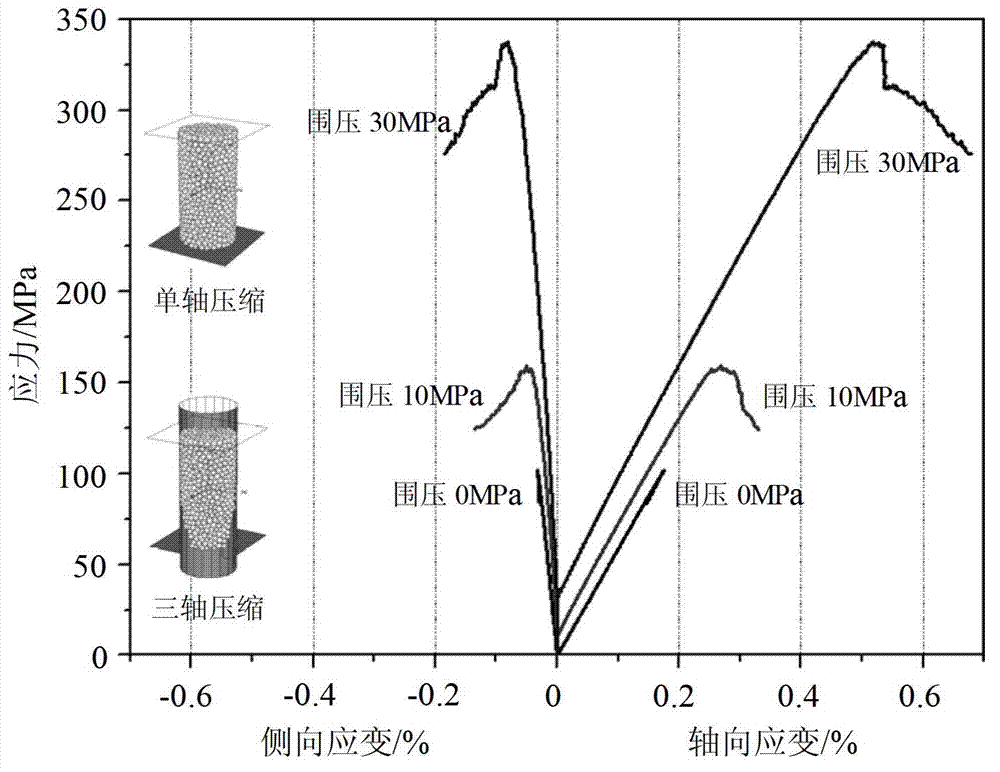

[0028] (1) Conduct indoor rock mechanics tests to obtain various macroscopic parameters of rocks sampled on site. Through the indoor uniaxial compression test, the uniaxial compressive strength σ of the rock is obtained ucs , elastic modulus E, and Poisson's ratio ν; through the indoor triaxial compression test, the compressive strength under different confining pressures can be obtained, and the Mohr's circle and strength envelope can be drawn to obtain the cohesion c and internal friction angle of the rock .

[0029] Table 1 shows the macro parameters of the rock obtained from the indoor mechanical test after the rock (dolomite) sample was retrieved from the site.

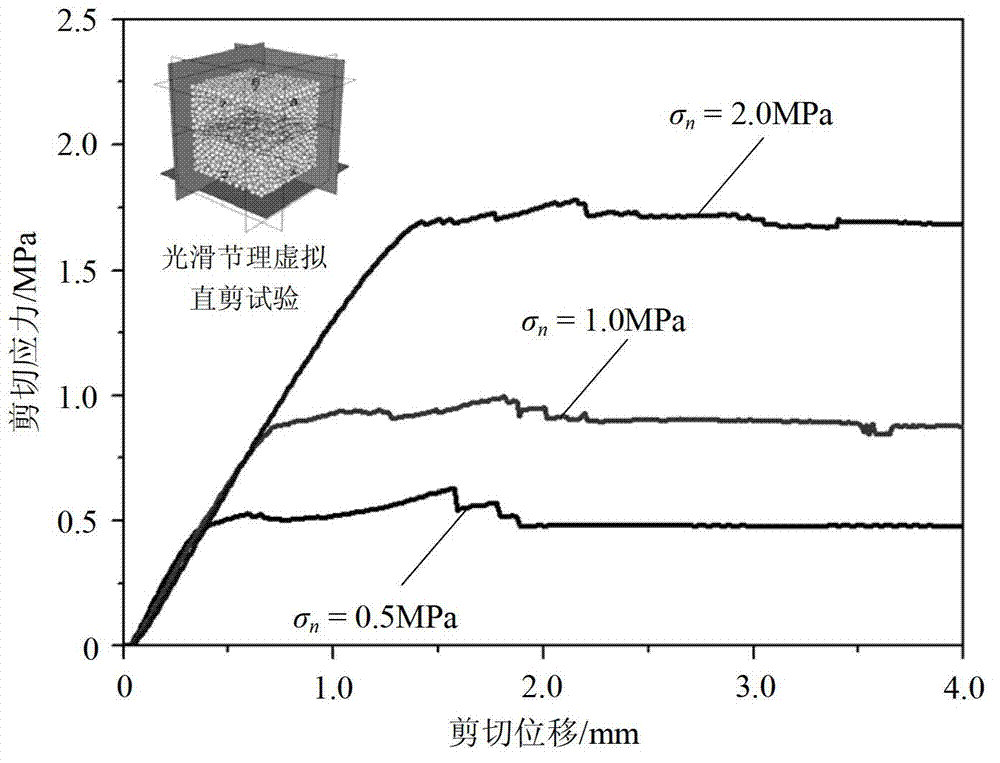

[0030] (2) Carry out indoor joint mechanics tests to obtain various macroscopic parameters of joints sampled on site. The shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com