Laterally constrained rock uniaxial compression test device

A technology of uniaxial compression test and confining compression, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of lack of test devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

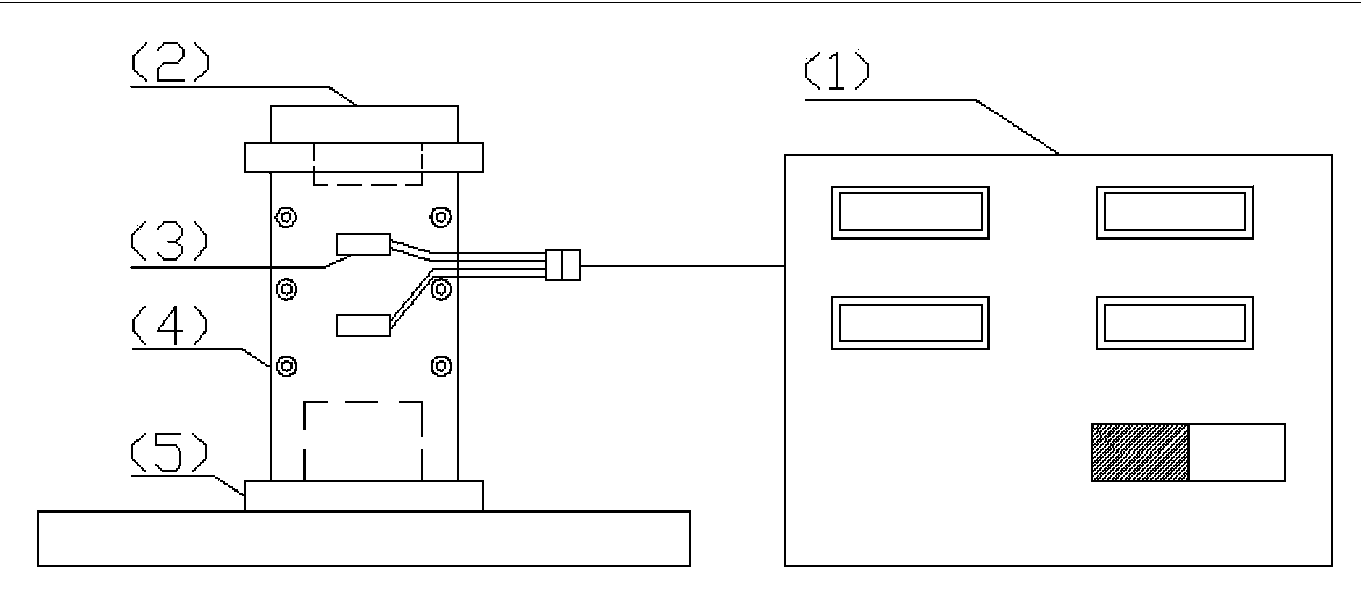

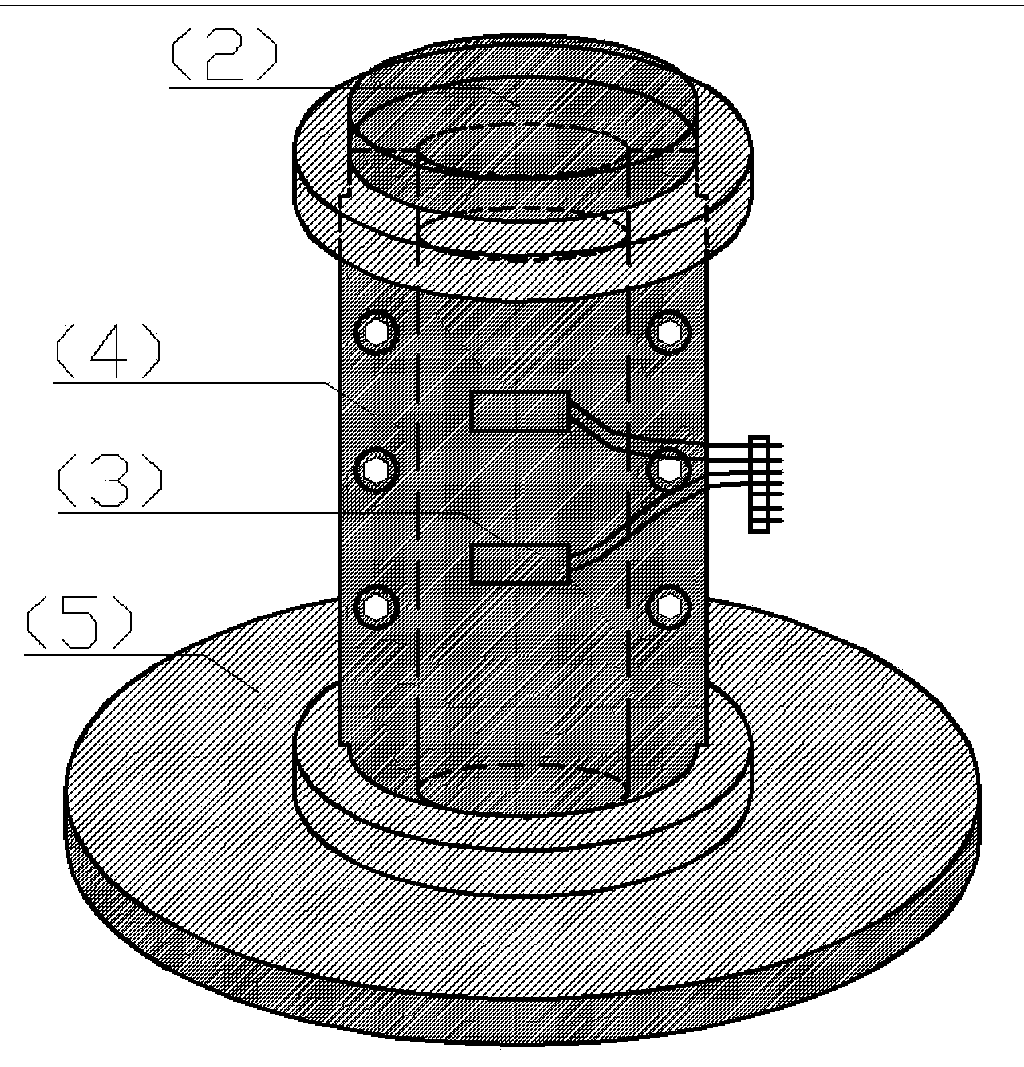

[0016] Such as figure 1 As shown, the present invention includes a resistive strain gauge 1, a T-shaped pressure bearing plate 2, a strain gauge 3, an annular cylindrical confined compression chamber 4 and an inverted T-shaped pressure bearing base 5; an annular cylindrical confined compressed chamber 4 It is composed of two semi-cylindrical shells with the same shape. There are screw holes on the edge of the two semi-cylindrical shells. The screws pass through the screw holes and will be fixed by the two semi-cylindrical shells to form a hollow cylinder. The annular cylindrical side is compressed The upper and lower openings of the chamber 4, the upper opening is provided with a T-shaped pressure bearing plate 2, and the T-shaped pressure bearing plate 2 is provided with a cylindrical protrusion extending into the interior of the annular cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com