Submerged pulse jet pulse parameter testing device and testing method

A pulse parameter and pulse jet technology, applied in the field of water jet, can solve the problems of inability to continuously acquire data, large attenuation of measurement data, inability to acquire high-frequency data, etc., to avoid inaccurate test results, to solve the time delay of conduction, to solve The effect of large pressure conduction attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

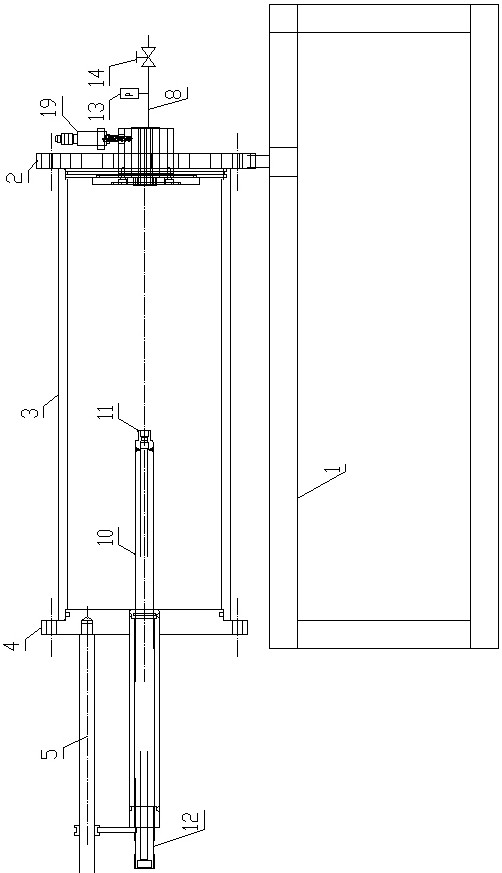

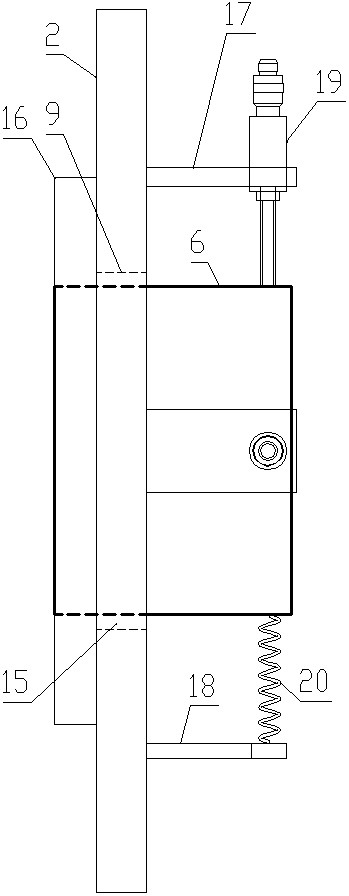

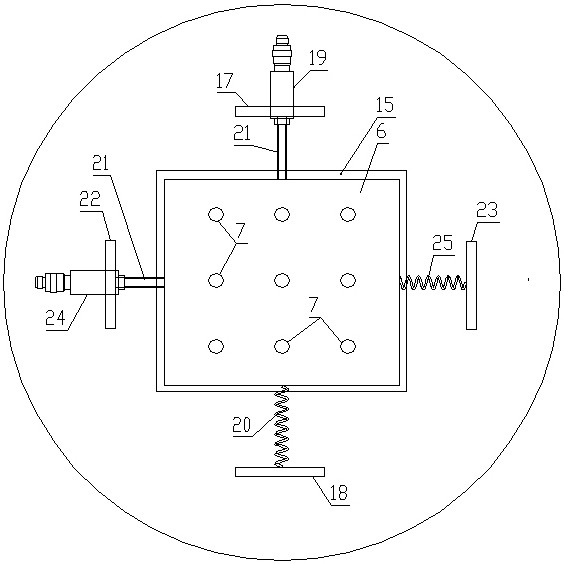

[0038] Such as Figure 1 to 3 As shown, the flooded pulse range of the present invention includes a support frame 1, a base 2 on the support frame 1, and a transparent cover 3 mounted on the base 2, and the transparent cover 3 is preferably made of tempered glass; transparent The other end of the cover 3 has a pair of end caps 4 of the base 2, and the upper cover 4 is connected to the upper cover 4; the chaper 6 is mounted on the base 2, and the hole plate 6 is distributed on the left-right direction through the hole plate 6. The through hole 7 is mounted in each through hole 7, and a piercing tube 8 for measuring pulse jet pulse parameters is mounted; the orifice plate 6 is a conventional structure, and the through hole 7 in the hole plate 6 is not shown. In order to avoid the influence of harness chaos, figure 2 Only one piercard 8 is shown. figure 2 and image 3 Piercing tube 8 is not shown.

[0039] The center hole 9 for the orifice plate 6 is opened at the center of the base 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com