Method for quantitatively measuring inhomogeneous deformation of nano-crystal material

A uniform deformation and quantitative measurement technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as inability to measure, complex causes of shear bands, and uneven deformation of nanocrystalline materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of samples: The tensile samples were ground and polished with diamond suspensions with a particle size of 3 μm, 1 μm, and 0.25 μm and emery paper on one side of the purchased raw materials, and the required samples were obtained by grinding and polishing to about 150 μm by electrical discharge machining . Marking is made on the tensile sample, the width and length of the marked area of the tensile sample are 10 mm and 30 mm respectively and the thickness is about 150 μm.

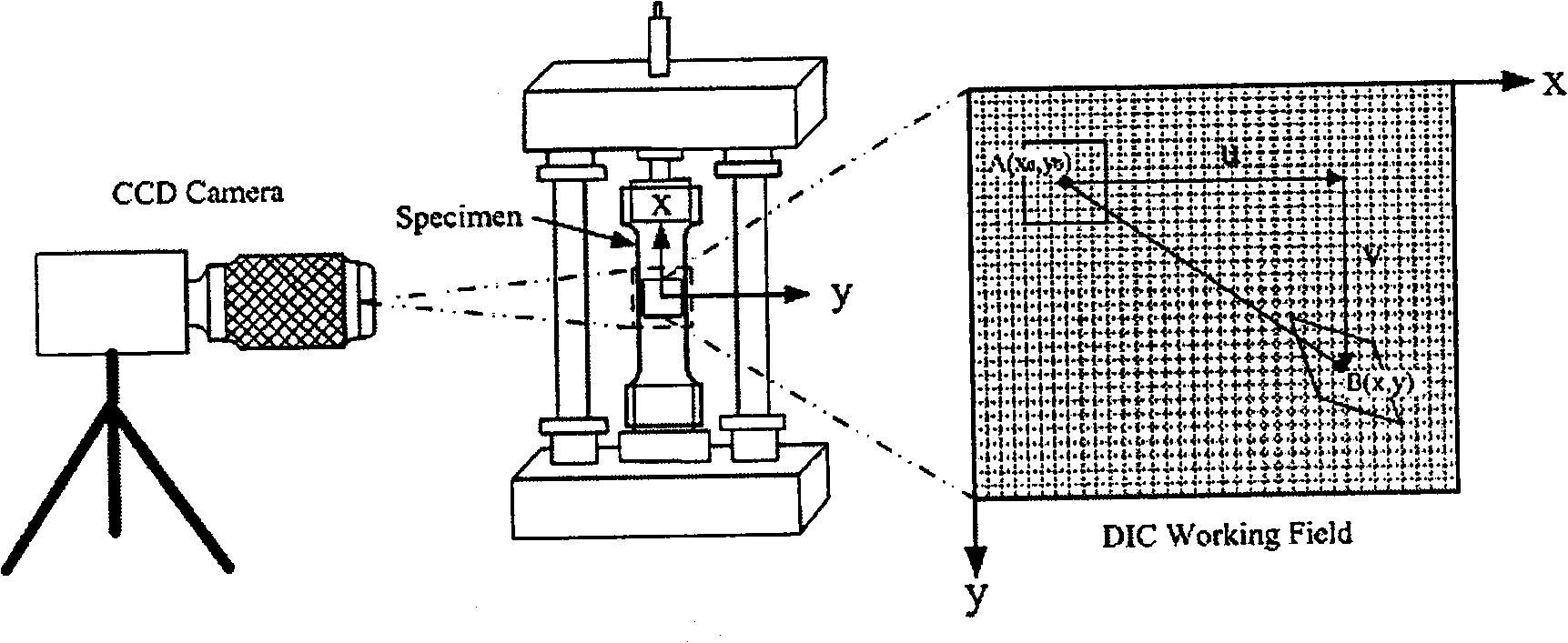

[0036] Mechanical testing and image acquisition: Tensile samples were tested by a Zwick BZ2.5 / TS1S universal testing machine at room temperature in displacement control mode, with a quasi-static strain rate of 10 -4 the s -1 The data obtained by the material testing system can draw a relatively accurate overall stress-strain curve. The equipped digital camera (model JAI CV-A1) is used to collect images of the sample surface and connect to the computer for recording. Image, if the load ...

specific Embodiment approach

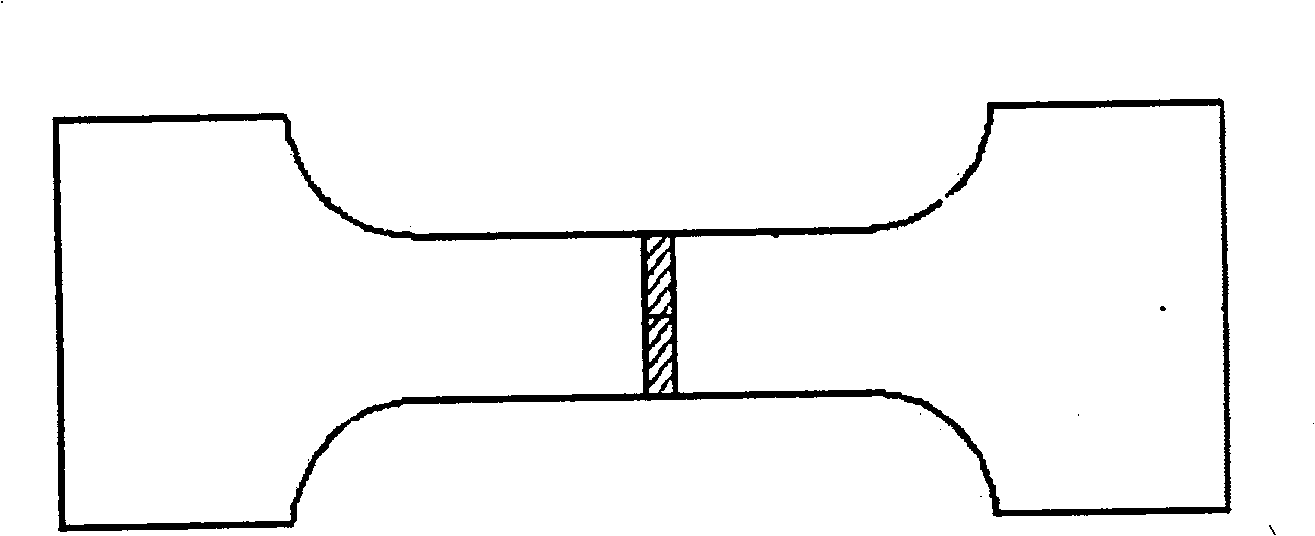

[0039] Fully dense nickel plates with a purity of 99.9% and a size of 76.2mm x 76.2mm x 0.2mm were purchased from the Canadian supplier Integran Technologies Inc, and their nominal particle size was about 20nm. The initial thickness of the nickel plate is about 0.2 mm, and the diamond suspension with a particle size of 3 μm, 1 μm, and 0.25 μm is used to grind and polish one side of it with emery paper to about 150 μm. For comparison, figure 1 The tensile specimens shown were EDM'd from ground and polished nanocrystalline nickel plates. The width and length of the marked area of the tensile specimen are 10 mm and 30 mm, respectively, and the thickness is about 150 μm, which is equal to the thickness of the nickel plate.

[0040] Tensile samples were tested by a Zwick BZ2.5 / TS1S universal testing machine at room temperature in displacement control mode, with a quasi-static strain rate of 10 -4 the s -1 loaded under the condition. The testing machine has a fixed bottom grip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com