Method for establishing aluminium alloy dynamic recrystallization model by using true stress-true strain curve

A recrystallized, true strain technique used to test material strength and other directions by applying stable tension/compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] 5083 plate was used in the test, and its chemical composition (mass fraction) is shown in Table 1

[0026] Table 1 Test 5083 plate chemical composition

[0027] Si

Fe

Cu

mn

Mg

Cr

Ni

Zn

Ti

Zr

be

Na

V

Al

0.08

0.05

0.01

0.6

4.61

0.1

0.15

0.034

0.029

0.24

0.0006

0.0008

0.048

the remaining

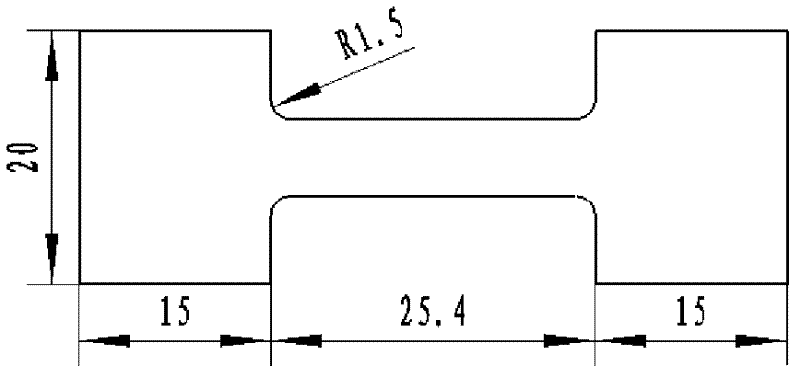

[0028] The high-temperature single-tension test is carried out on a computer-controlled electronic universal thermal tensile testing machine RG2000-20, and the geometric dimensions of the sample are as follows:

[0029] figure 1 As shown, the sheet thickness is 2mm.

[0030] The strain rate used is 6.56E-5~6.56E-3S-1; the temperature is 623K, 673K, 723K, 773K, 793K, 808K.

[0031] The sample needs to be kept warm for 5 minutes before tensile deformation, so that the sample evenly reaches the set target temperature.

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com