Test method for performing rock direct stretching by using axial centering positioning device

A centering positioning and test method technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., to achieve the effects of broad application prospects, significant economic benefits, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

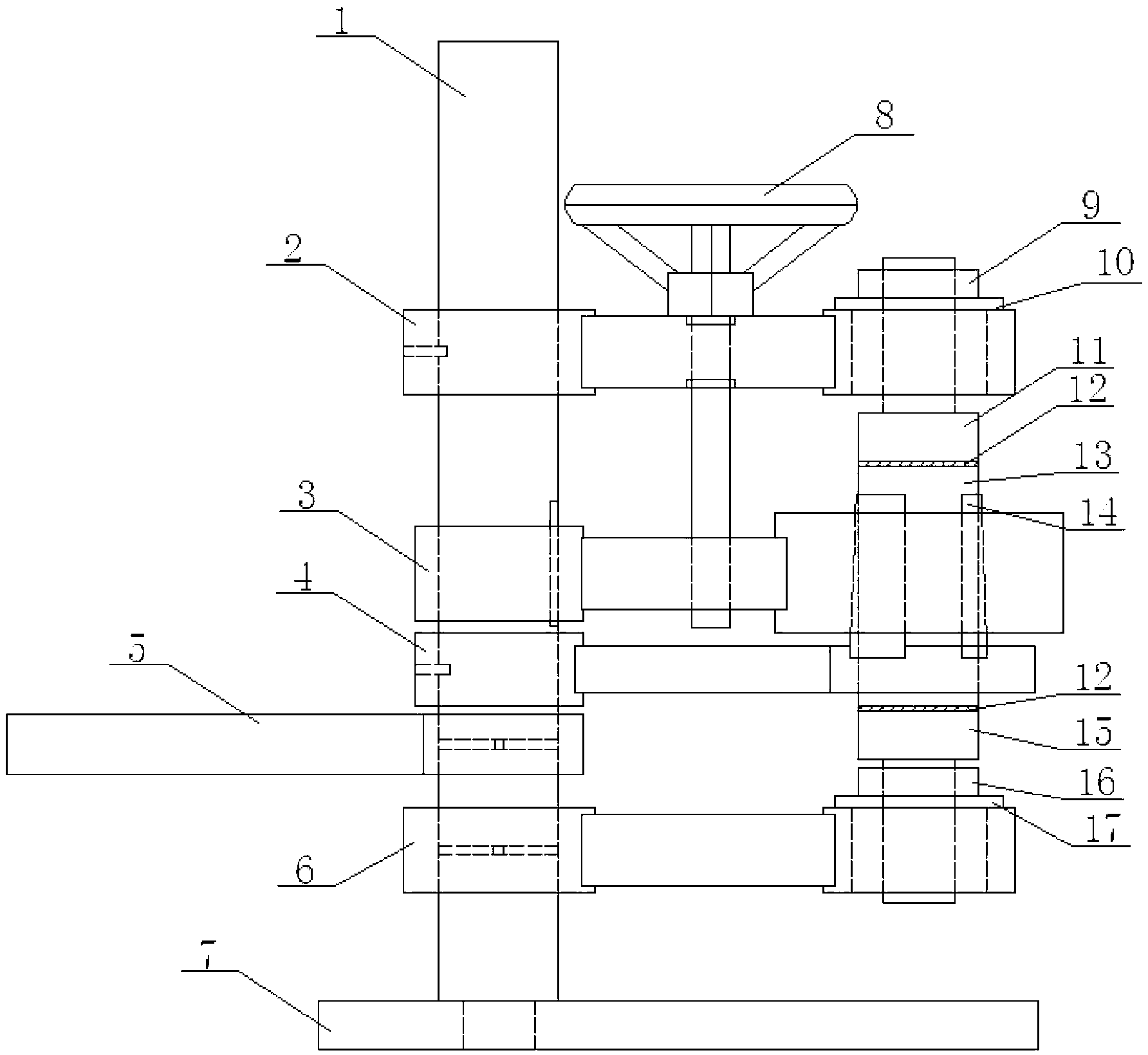

[0046] figure 1 Among them, the adhesive centering positioning device is mainly composed of column 1, upper and lower positioning sleeves 2, 6, specimen clamping sleeve 3, valve supporting plate 4, specimen supporting plate 5, bottom plate 7, rotating handwheel 8, upper The pull-down head adjustment knob 9,16, the upper and lower pull-down head positioning rings 10,17, the upper and lower pull-down heads 11,15, and the wedge-shaped clamping valve 14 constitute.

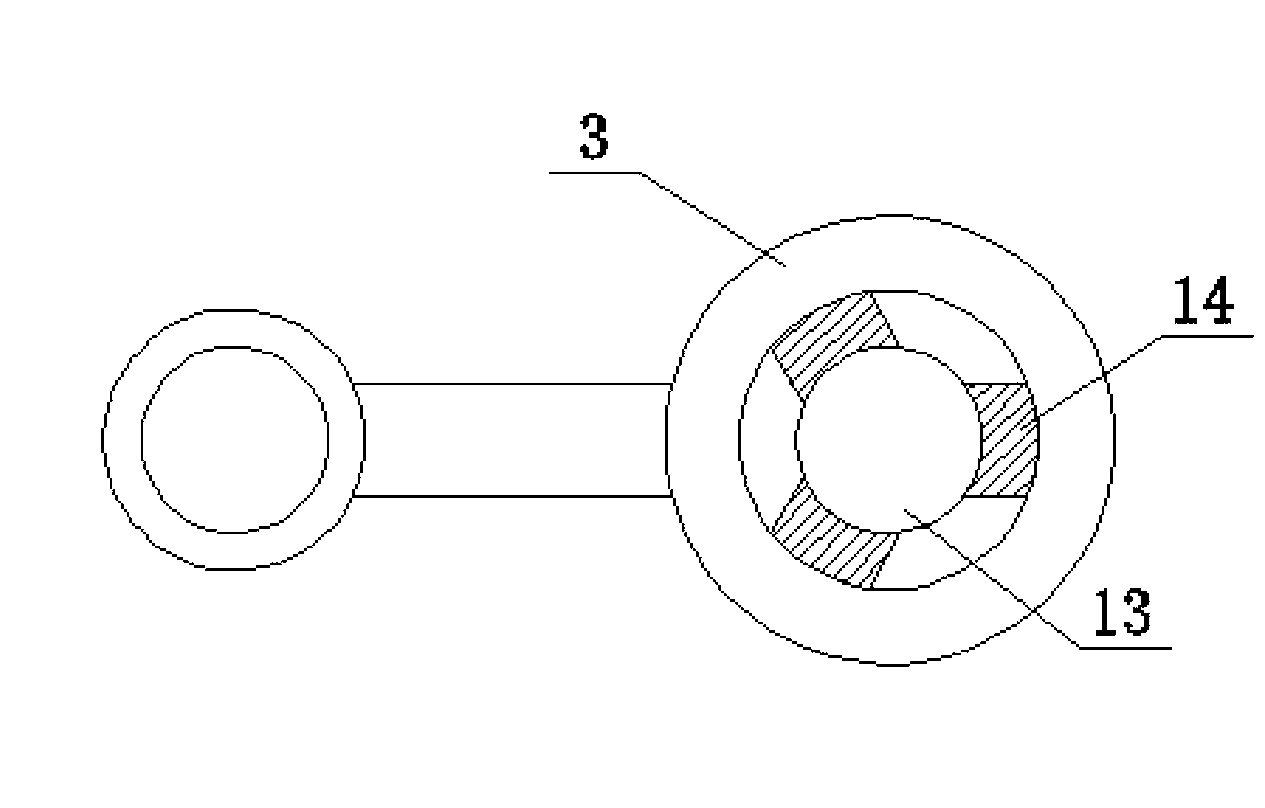

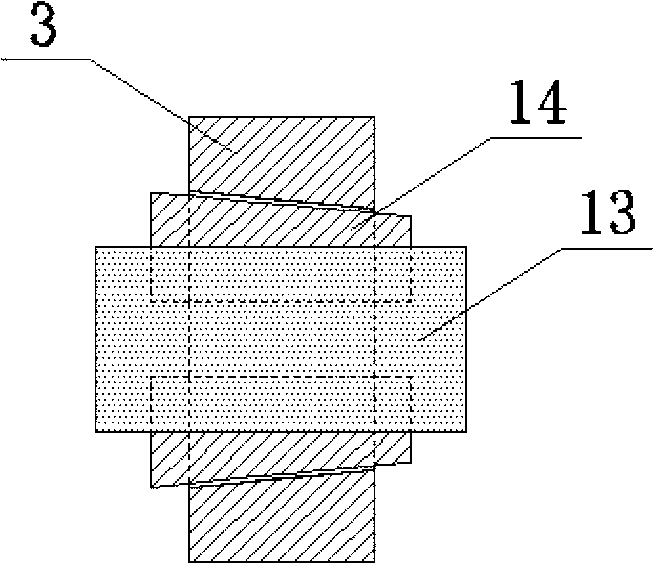

[0047] The specimen clamping sleeve 3 and the wedge-shaped clamping valve 14 (Fig. 2(a), Fig. 2(b)) are the core components. When the rock specimen 13 is bonded, it can ensure that the center line of the specimen 13 is in line with the vertical direction. The centerlines of the heads 11 and 15 coincide to eliminate the eccentricity caused by bonding the test piece 13 . Wherein the inner surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com