Handheld diameter-variable reinforcing steel bar electric derusting device and using method thereof

A hand-held, steel-bar technology, applied in the field of hand-held variable-diameter steel bar electric rust removal devices, can solve the problems of high labor intensity, reduced bearing capacity of reinforced concrete, affected use functions, etc., and achieves reduced labor intensity, simple and lightweight structure, The effect of easy hand-held operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

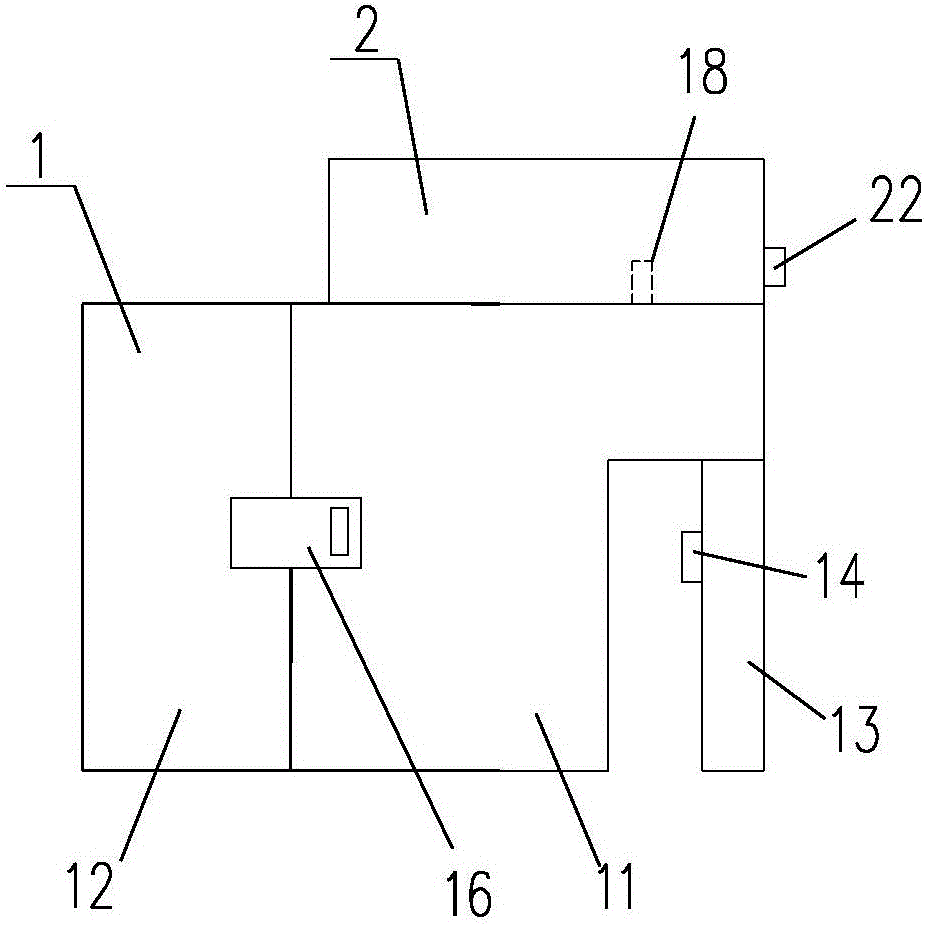

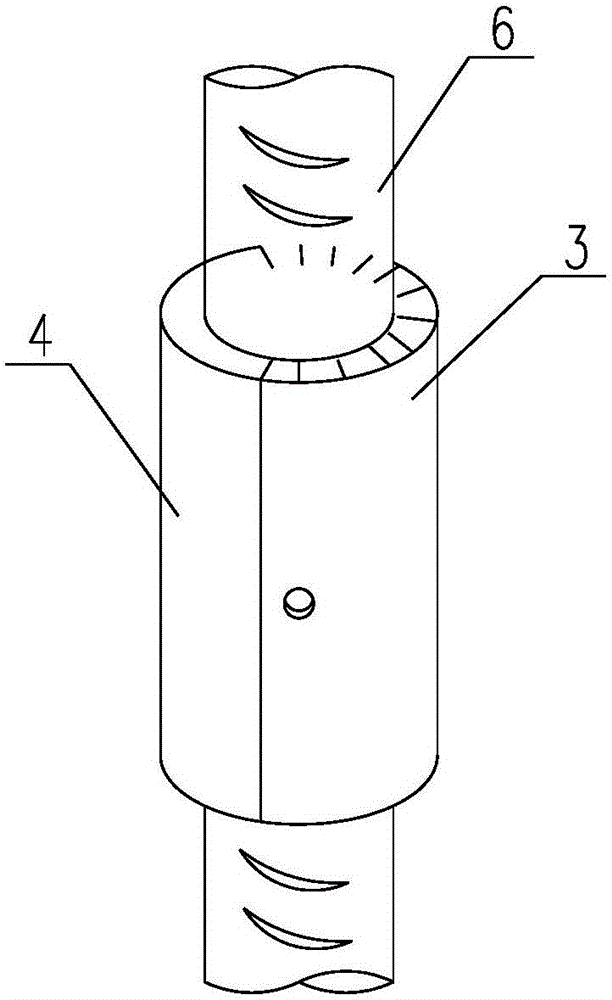

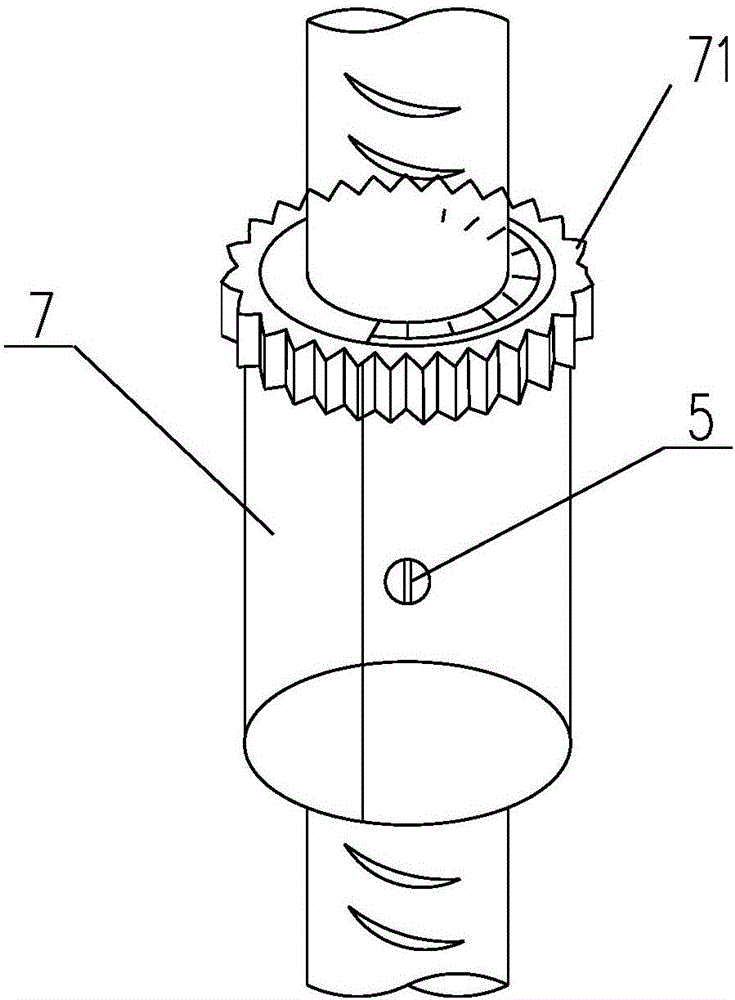

[0029] Such as figure 1 As shown, a hand-held variable-diameter steel bar electric rust removal device according to the present invention includes a fuselage 1, a cylinder body 7, a wire brush plate 3, an elastic fixing member 4, a gear motor 8 and a rust remover spray box 2; if Figure 4 As shown, the fuselage 1 is a rotating opening and closing structure, and the cylinder 7 is composed of two relatively combined half cylinders; as figure 2 As shown, the steel wire brush plate 3 is made of steel wire into an arc-shaped structure, and is fixed in the cylinder body 7 by the elastic fixing member 4. The steel wire brush plate 3 and the elastic fixing member 4 form a cylindrical structure, and the cylindrical space inside it is used for Containing reinforcement 6; as image 3 As shown, a ring gear 71 is arranged on the outer side of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com