Battery transferring frame

A transfer rack and battery technology, applied in transportation and packaging, containers, packaging, etc., can solve the problems of time-consuming and labor-intensive, easy to damage batteries, etc., and achieve the effects of avoiding scratches, simplifying the structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

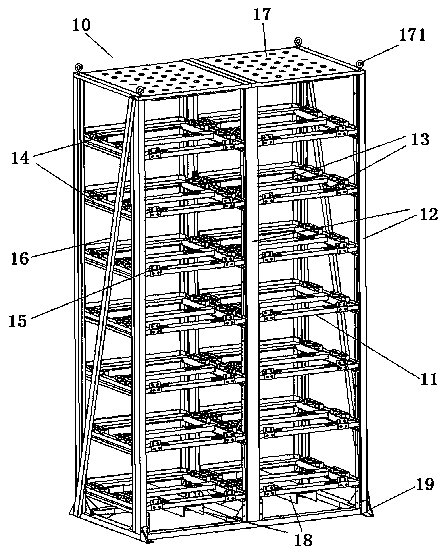

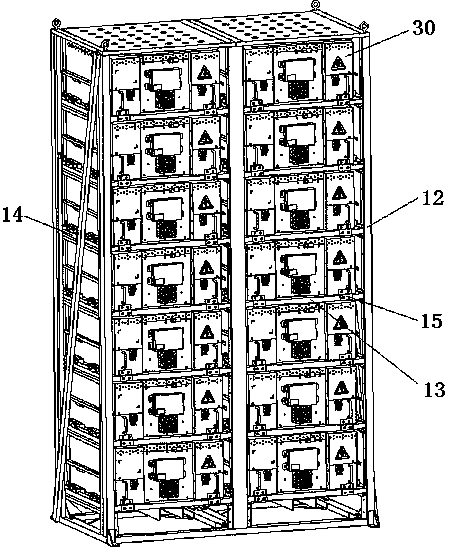

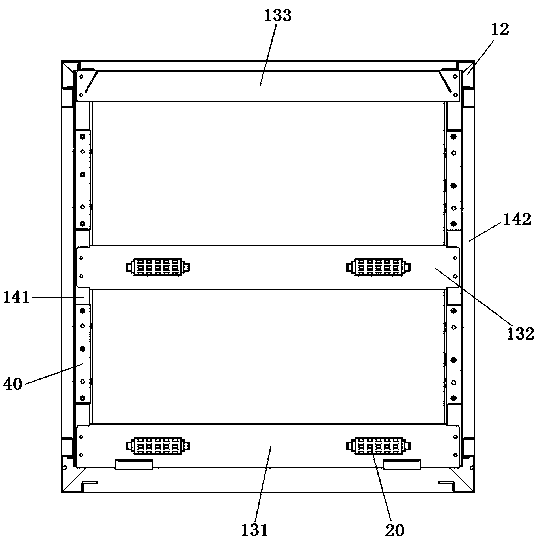

[0046] Embodiment 1 of the battery transfer rack in the present invention: the battery transfer rack in the present invention can carry battery sub-boxes, and the operator can carry out long-distance or short-distance transfer of multiple battery sub-boxes by moving the battery transfer rack. Such as figure 1 and figure 2 As shown, the battery transfer frame 10 includes a carrier frame 11 as a main body. The carrier frame 11 in this embodiment includes six columns 12 extending vertically, and the lines connecting the six columns 12 form a rectangle. The bearing frame 11 also includes supporting brackets that are connected to the uprights 12 at intervals along the up-down direction, that is, multi-layer supporting brackets are arranged in the up-down direction, and in the up-down direction, two adjacent supporting brackets are formed for The battery storage compartment supporting the battery insertion box 30 has an opening for the battery to enter and exit the battery storage...

Embodiment 2

[0060] Embodiment 2 of the battery transfer rack in the present invention: the difference from the above embodiment is that the carrier rack in this embodiment is provided with an independent box body, the battery storage compartment is formed by the box body, and the battery is loaded into the corresponding box during transfer. In the box body, a bottom support structure is arranged on the bottom wall of the box body, and a side guide structure is arranged on the side wall.

Embodiment 3

[0061] Embodiment 3 of the battery transfer frame in the present invention: the difference from the above embodiments is that the carrier frame in this embodiment includes a column and a plate body connected to the column, and the plate body includes side plates arranged in a vertical direction. As well as the top plate and the bottom plate arranged in the horizontal direction, the battery storage compartment is jointly surrounded by the side plates, the top plate and the bottom plate. Bottom support structures are arranged on the base plate and side guide structures are arranged on the side plates.

[0062] Embodiment 4 of the battery transfer rack in the present invention: the difference from the above embodiments is that the bottom supporting structure in this embodiment is only arranged on the longitudinal beams. In other embodiments, bottom support structures are provided on both the longitudinal beams and the cross beams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com