Winding tool of stator coil

A winding tool and stator coil technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problem of lack of simple and convenient winding tools for small motor coils, and achieve the effect of simple structure and high winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

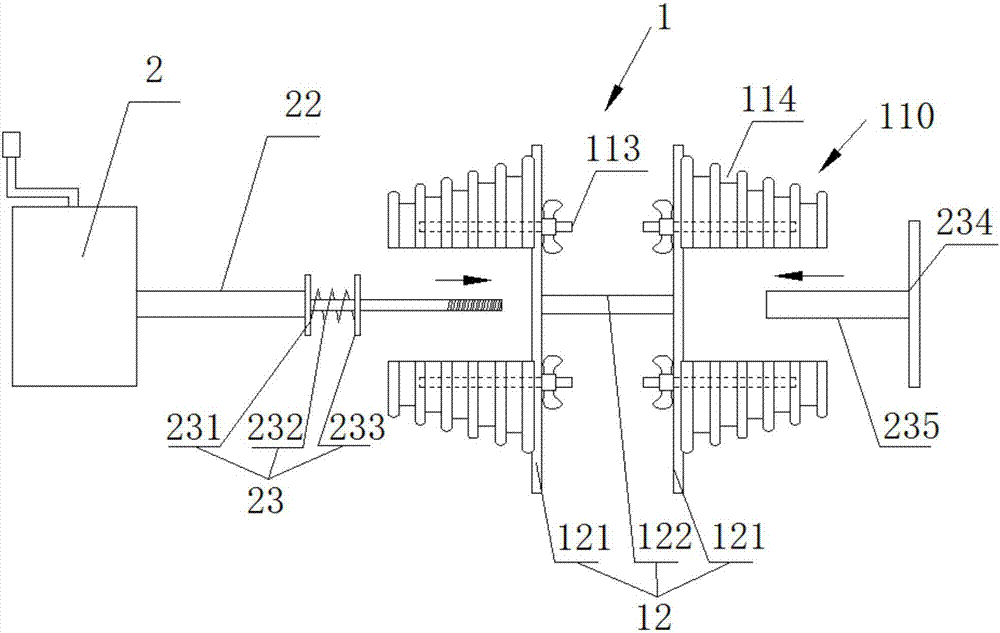

[0027] Such as figure 1 , figure 2 , image 3 As shown, a winding tool for a stator coil includes a winding mechanism 1, a driving mechanism 2, and a counter; the driving mechanism 2 drives the winding mechanism 1 to rotate;

[0028] The driving mechanism 2 is a hand-operated winding machine; the hand-operated winding machine includes a crank; the crank is linked with the drive shaft 22 . The counter is used to count the number of turns of the winding section. How to realize the counting function of the counter, as well as its circuit structure, and the assembly structure of the hand-operated winding machine are all prior art, and will not be described in detail here.

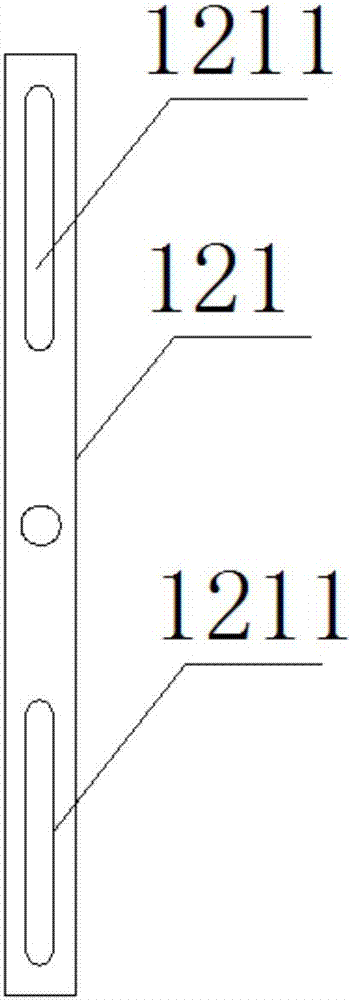

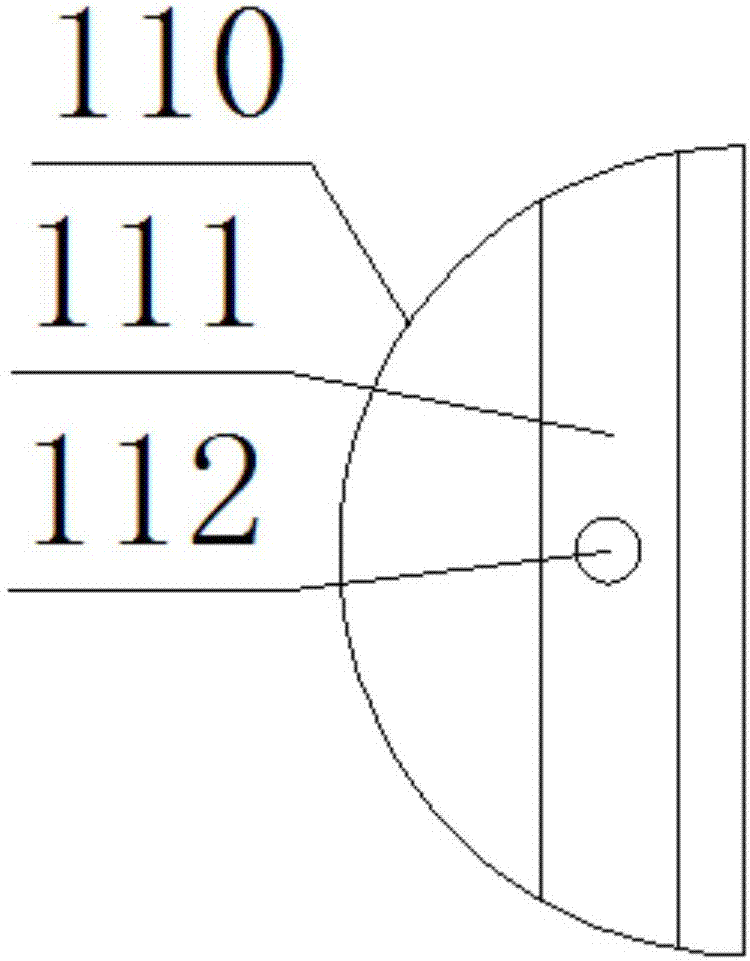

[0029] The winding mechanism 1 includes a winding part 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com