Blade assembling device of spiral conveying equipment

A technology of screw conveying and assembling device, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem of time-consuming and laborious processing of spiral blades, and achieve the effect of simple structure and convenient welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Such as Figure 4 to Figure 12 As shown, the present invention mainly includes a bracket 2, a connecting plate 22, a moving unit and a clamping adjustment unit, and the present invention will be described in detail below with reference to the accompanying drawings.

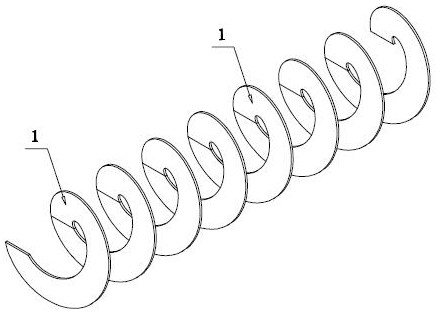

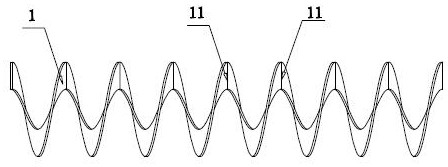

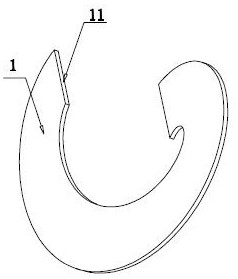

[0028] Such as Figure 1 to Figure 3 As shown, the helical blades of the screw conveying equipment include several individual blades 1 arranged in sequence and fixed together by welding. Several individual blades are arranged on the main shaft 12 in sequence, and the main shaft and the individual blades are welded and fixed. Both ends of a single blade are respectively provided with contact surfaces 11, and every two adjacent single blades are in contact with each other through the contact surfaces.

[0029] Such as Figure 4 , Figure 5 As shown, the bracket 2 is a metal piece with a U-shaped structure, and the brackets are a pair arranged on the left and right. The brackets are used to contact the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com