Three-silver low radiation film glass capable of being subsequently processed

A low-emissivity film and glass technology, applied in the field of triple-silver low-emission film glass, can solve the problems of long patch cycle, inability to coat, high glass transportation cost, etc., and achieve the effect of various colors, stable optical performance and low emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

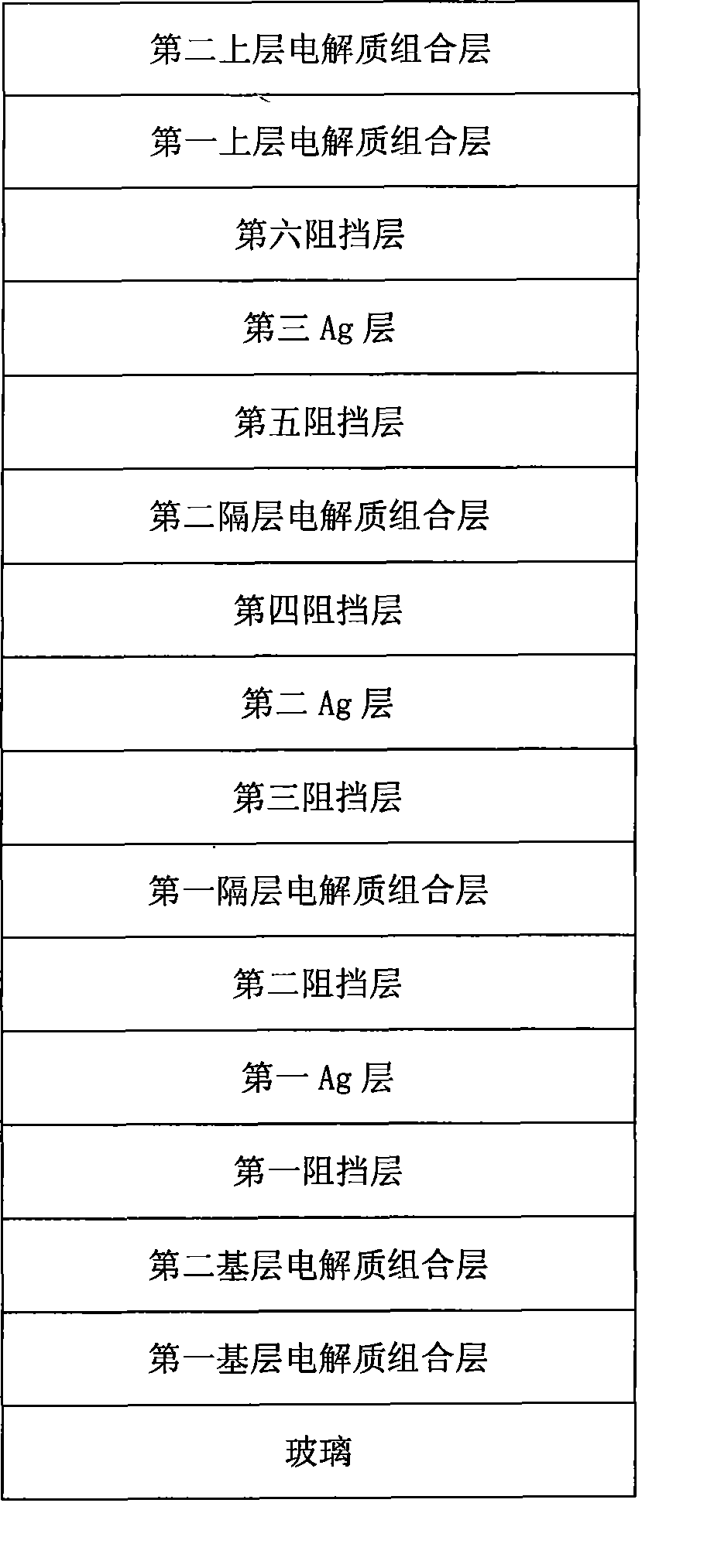

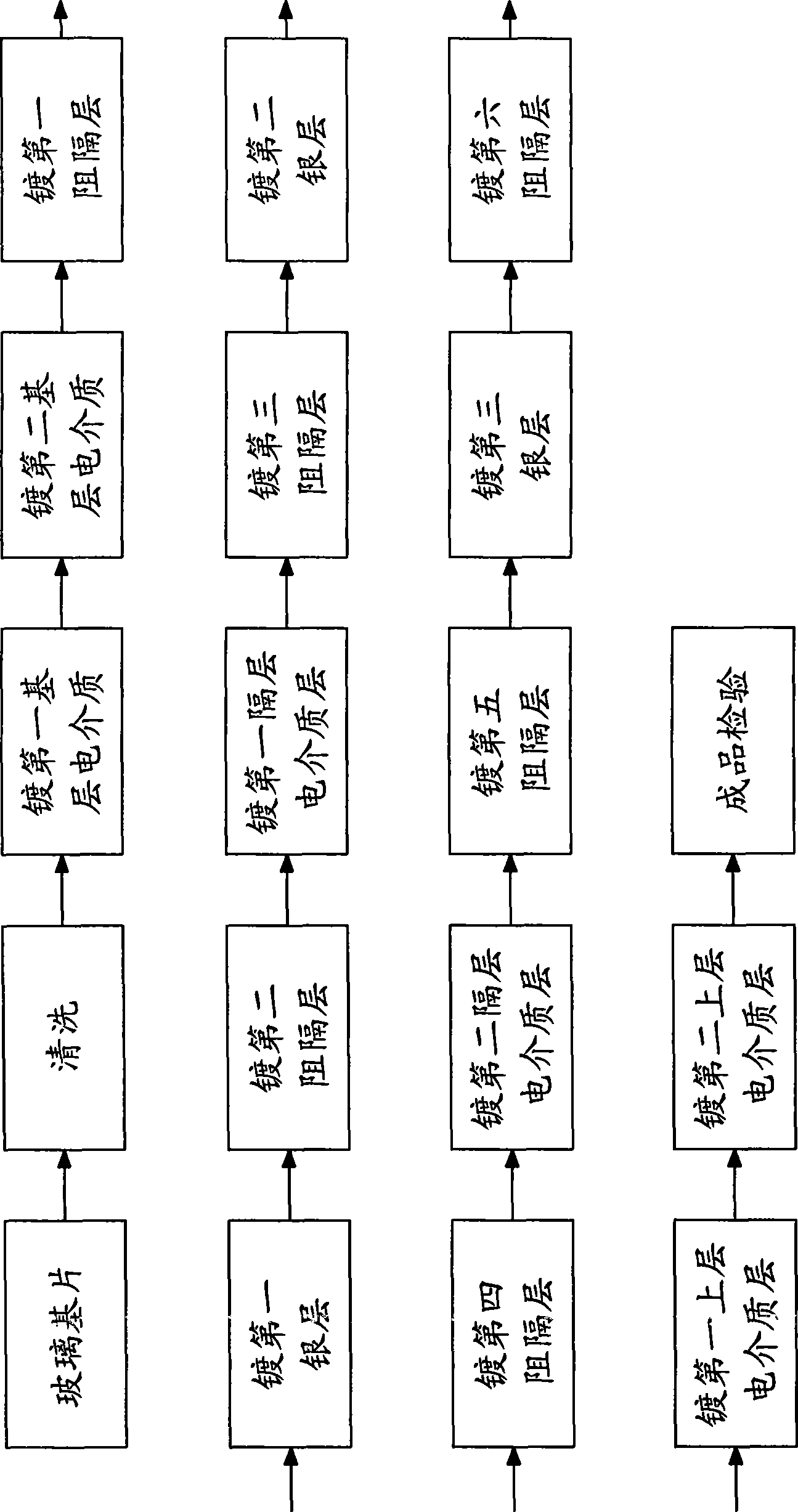

[0045]The film structure of the three-silver low-e film glass that can be processed subsequently provided by the present invention is: glass substrate / first base dielectric composite layer (5.0-10.0nm) / second base dielectric composite layer (5.0-10.0nm) / First barrier layer (0.5~5.0nm) / first Ag layer (8-35nm) / second barrier layer (0.5~5.0nm) / first interlayer dielectric combination layer (50-70nm) / third barrier layer ( 0.5~5.0nm) / Second Ag layer (8-35nm) / Fourth barrier layer (0.5~5.0nm) / Second interlayer dielectric combination layer (60-80nm) / Fifth barrier layer (0.5~5.0nm) / Third Ag layer (8-35nm) / Sixth barrier layer (0.5-5.0nm) / First upper dielectric combination layer (10-35nm) / Second upper dielectric combination layer (10-30nm).

[0046] Each dielectric film layer is a metal or non-metal oxide or nitride deposited by vacuum sputtering, such as TiO 2 , ZnSnO x , SnO 2 , ZnO, SiO 2 , Ta 2 O 5 , BiO 2 , Al 2 O 3 , ZnAl 2 O 4 , Nb 2 O 5 , Si 3 N 4 , AZO, etc.

[0047] In practical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com