Base plate processing device,base plate processing method and progarm

A technology for a substrate processing device and a substrate processing method, which is applied in the direction of electrical program control, comprehensive factory control, instruments, etc., can solve the problems of production capacity (decreased processing capacity, deterioration of product substrate productivity, etc.), and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

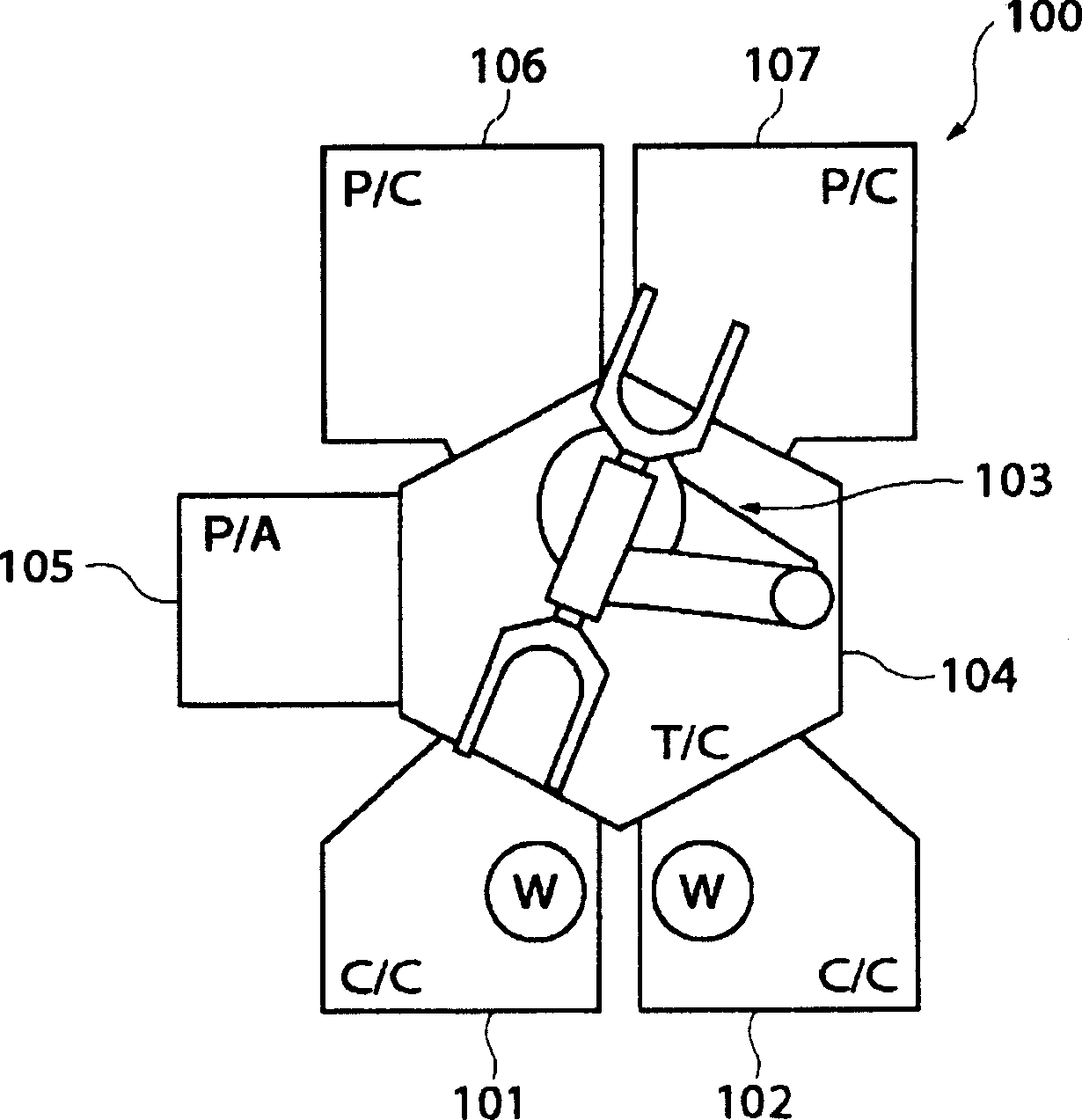

[0078] Embodiments of the present invention will be described in detail below with reference to the drawings.

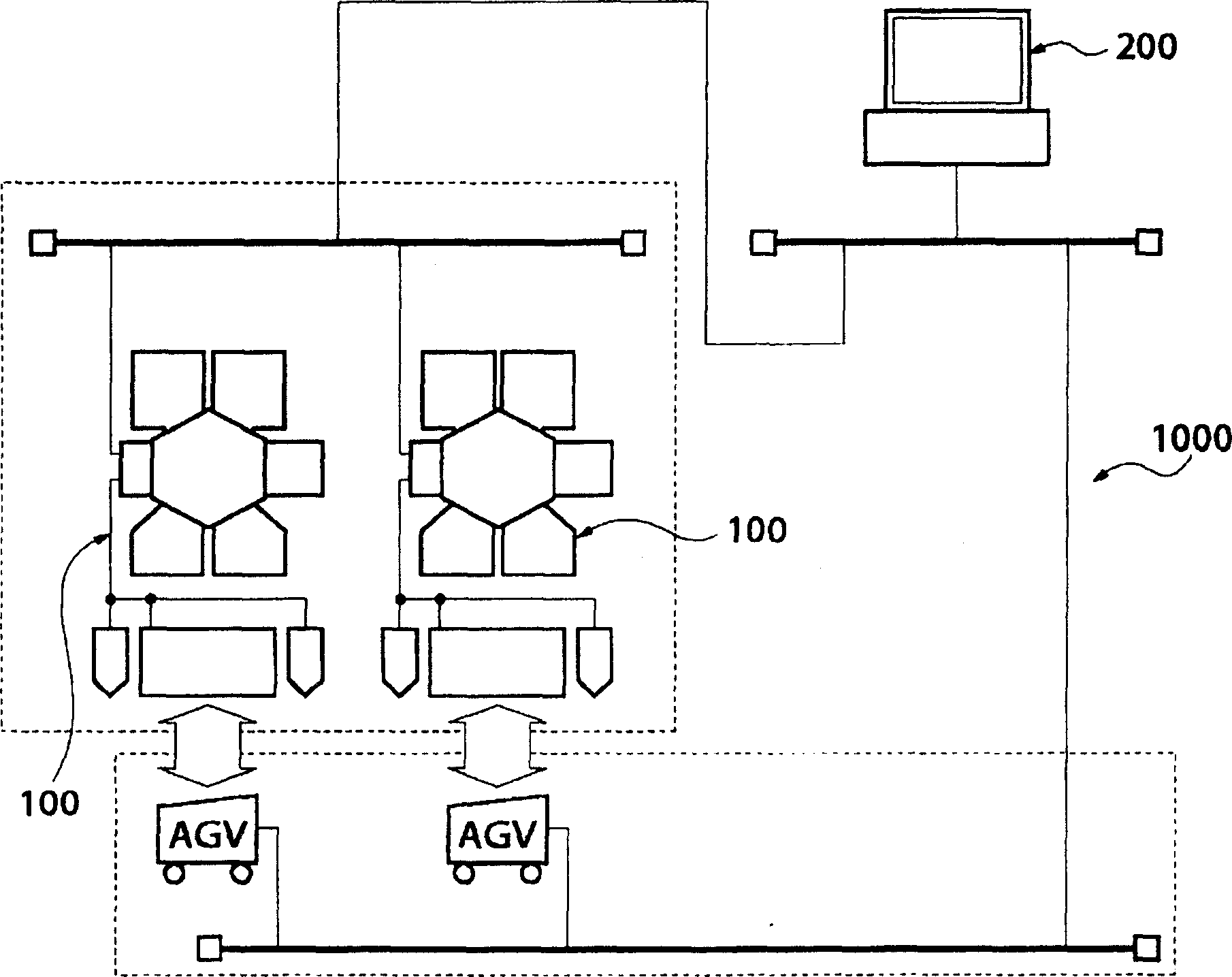

[0079] figure 1 It is a schematic block diagram showing the configuration of a substrate processing system including the substrate processing apparatus of the present embodiment.

[0080] figure 1The substrate processing system 1000 shown is provided with: at least one etching processing apparatus 100 as a substrate processing apparatus, and a device for transporting a wafer cassette described later that stores semiconductor substrates (hereinafter referred to as substrates) to the etching processing apparatus 100. An automatic transfer device (AGV: Auto Guided Vehicle), and a host computer (host computer) 200 connected to the AGV and the etching processing device 100 via a network.

[0081] In the host computer 200, transfer recipes, product processing recipes, and simulation processing recipes described later are pre-registered and installed as programs, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com