Intelligent flexible production line based on automatic robot assembling and operating method thereof

A flexible production line and automatic assembly technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of outdated technology, small batches, and many configurations, and achieve high processing quality, avoid pollution, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

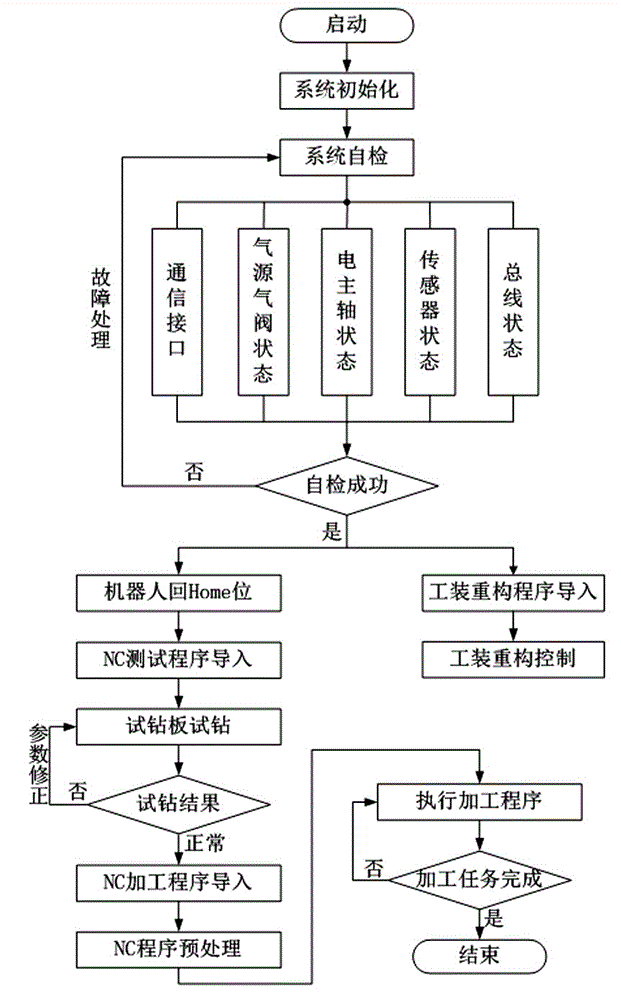

[0054] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0055]An intelligent flexible production line for robot automatic assembly, the production line includes an industrial computer, a track and a heavy-duty mobile platform, an end effector, an industrial robot, a nail feeding system, a vacuum chip suction device, an industrial robot control cabinet, a main control cabinet, a test Tool stations, flexible tooling, and laser trackers. The industrial robot, the nail feeding system, the vacuum suction device, the industrial robot control cabinet, and the main control cabinet are all installed on the heavy-duty mobile platform. As the industrial robot moves, the end effector is mounted on the industrial robot, Flexible tooling and a knife testing station are arranged on one side of the track.

[0056] The track i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com