Rock tensile test device under confining pressure effect and test method thereof

A tensile test and rock technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of weak practicability and poor accuracy of results, and achieve reduced test costs, easy control, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

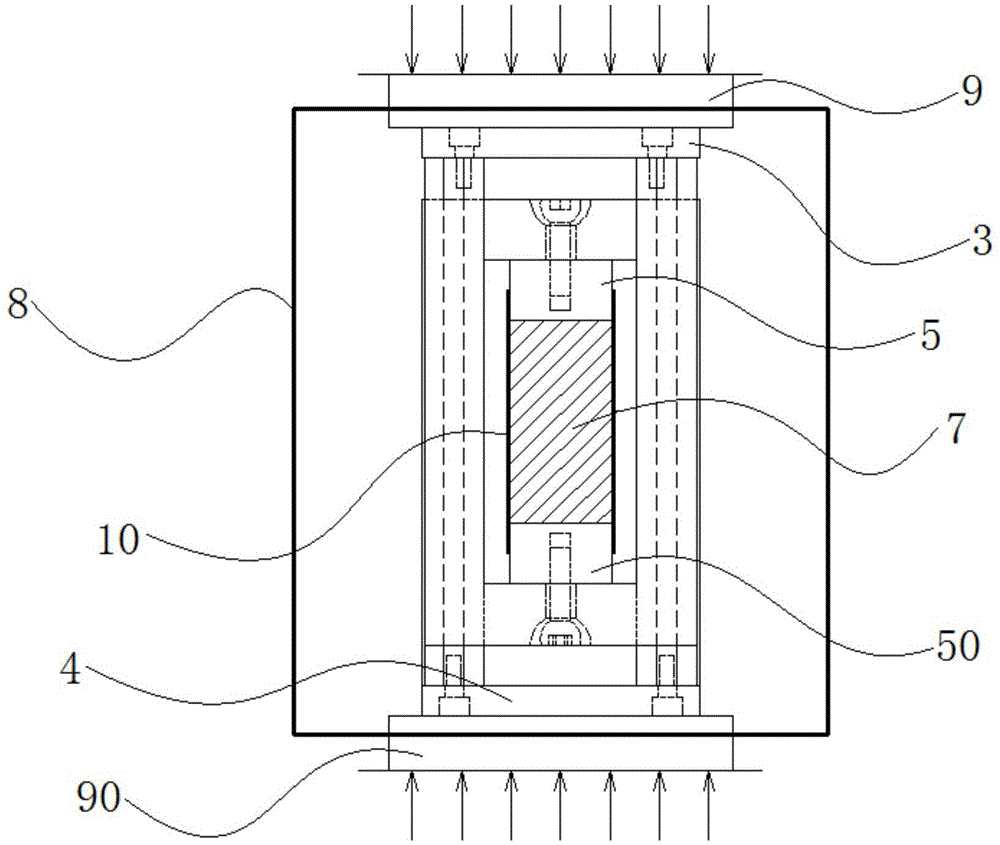

[0060] This embodiment discloses a rock tensile test device under confining pressure, including component I1, component II2, connecting plate 3, backing plate 4, slider I5, and slider II50.

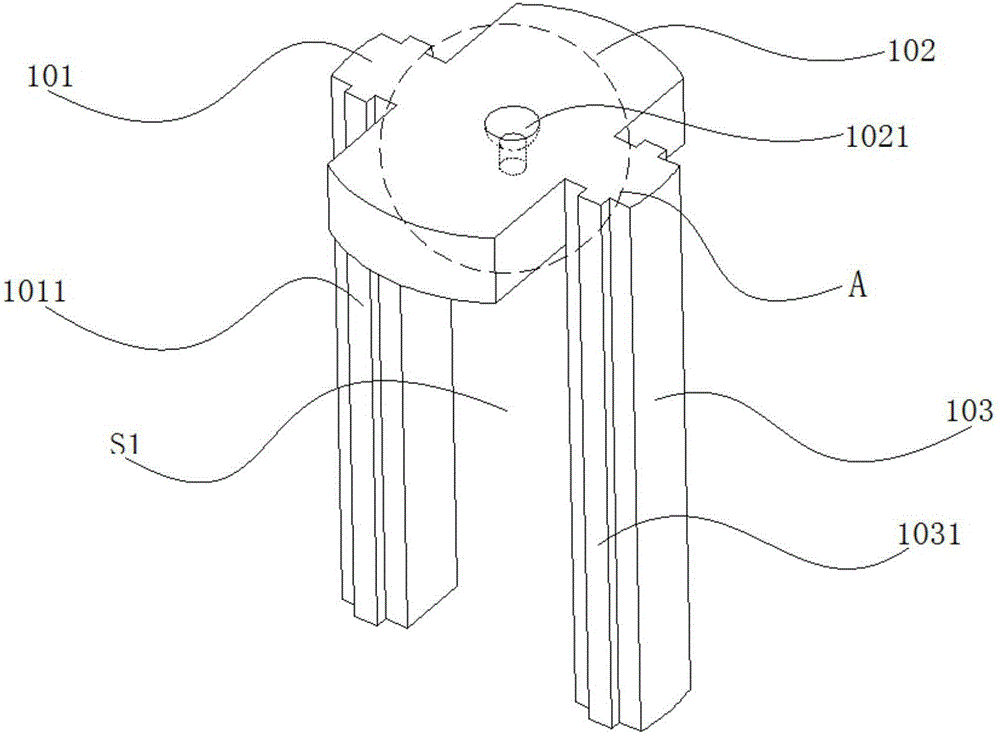

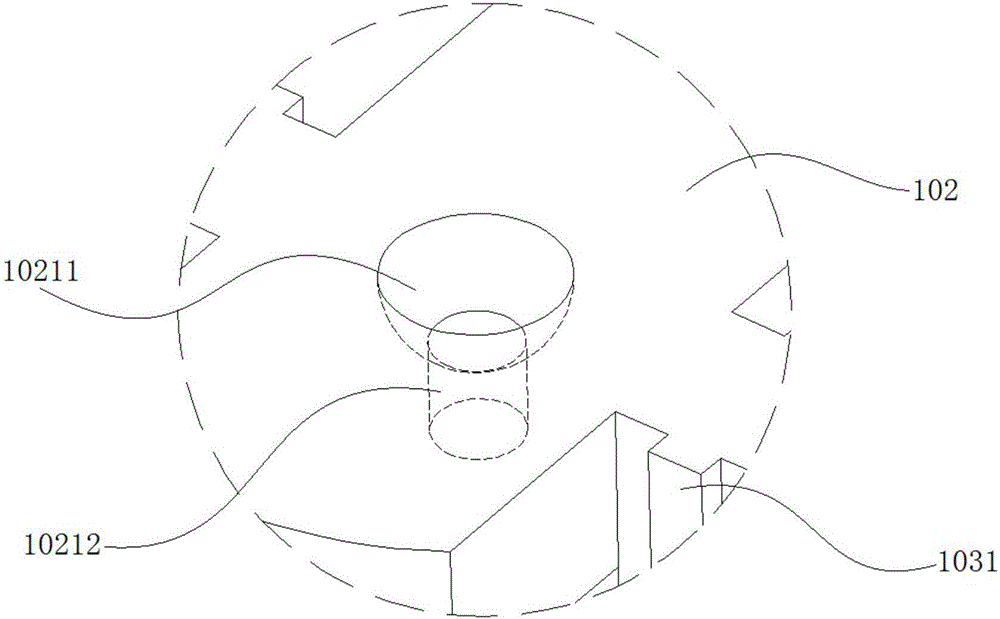

[0061] see figure 2 , image 3 and Figure 4 , the member I1 includes a force transmission column I101, a beam I102 and a force transmission column II103. The beam I102 is connected between the force transmission column I101 and the force transmission column II103, and the upper surfaces of the three are flush. The force transmission column I 101, the beam I 102 and the force transmission column II 103 are integrated. The force transmission column I101, the beam I102 and the force transmission column II103 enclose the semi-enclosed space IS1.

[0062] The cross-section of the beam I102 is straight-sided elliptical (that is, the two opposite sides of the rectangle are replaced by two identical arcs, and the area of the newly formed figure is larger than the area of the original re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com