Device for tensile test of high temperature oxidizable metal material

A technology of easily oxidizable metal and tensile test, applied in the direction of measuring device, analyzing material, using stable tension/pressure test material strength, etc. Simple clamping process, achieving cooling speed, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

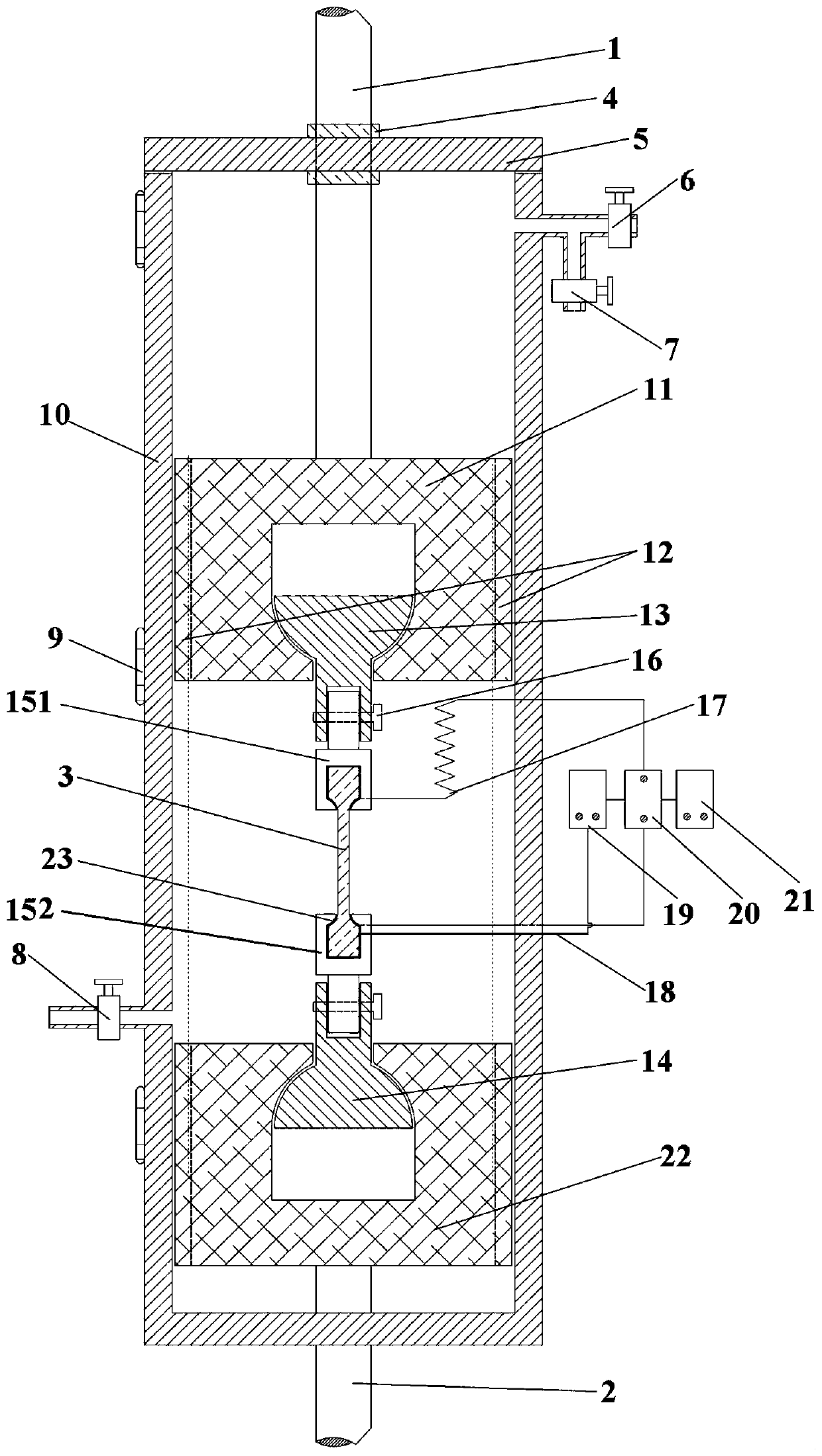

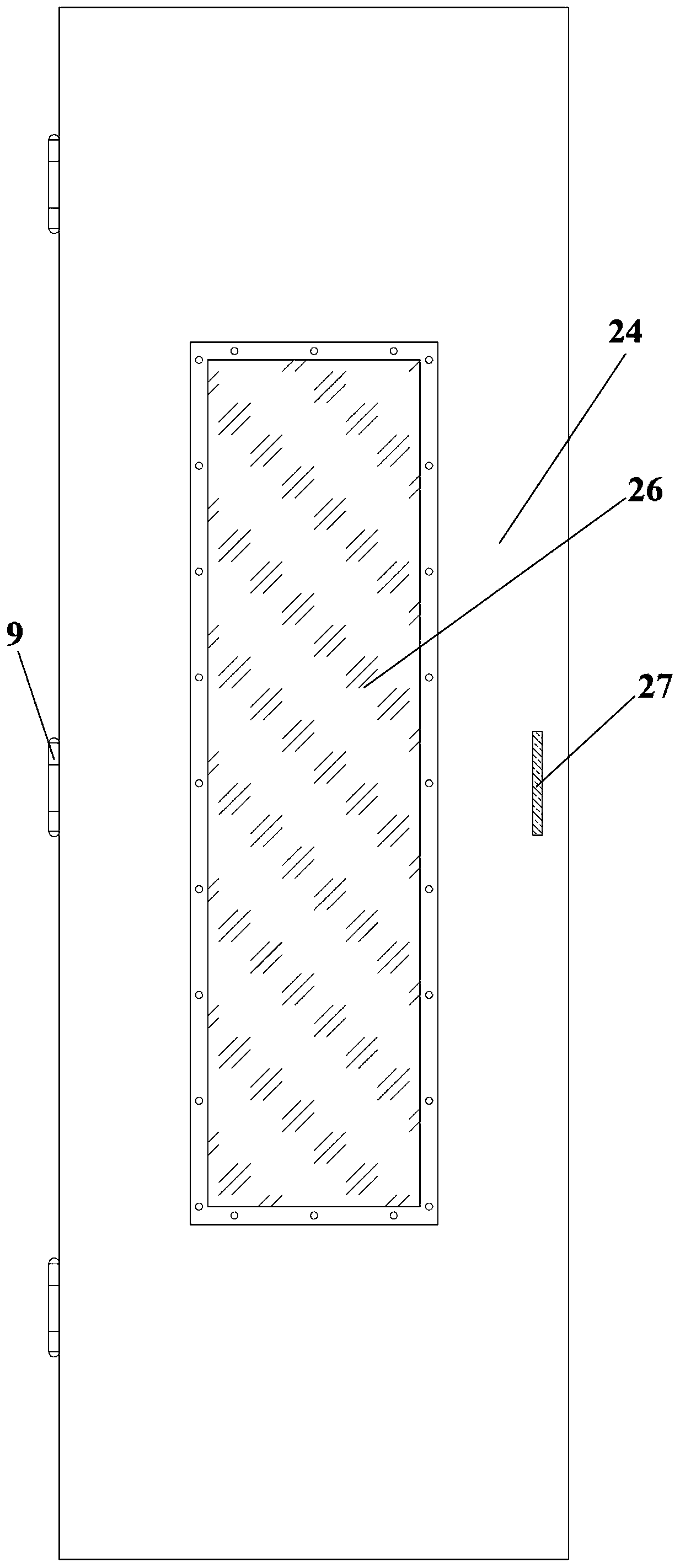

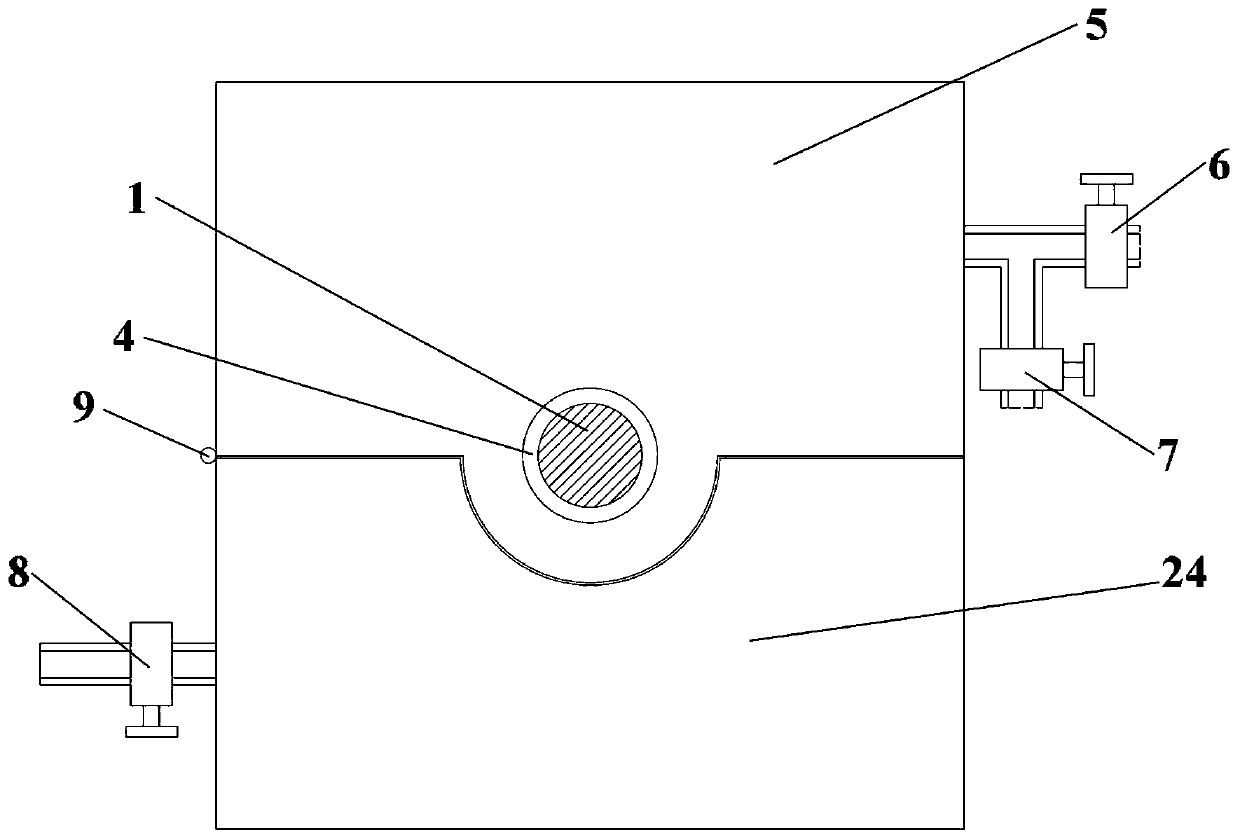

[0035] A device for tensile testing of high-temperature easily oxidizable metal materials provided in this embodiment, such as figure 1 As shown, it includes: vacuum chamber 10, vacuum chamber door 24, vacuum system, temperature control unit, upper beam loading rod 1, upper load transmission frame 11, lower beam fixing rod 2, lower load transmission frame 22, upper ball tie support 13. The upper ball-twist bearing 14, the upper clamp 151 and the lower clamp 152; figure 2 As shown, the vacuum chamber door 24 is provided with a transparent observation window 26, and is connected with the vacuum chamber 10 hinge 9, and a door handle 27 for convenient closing and opening is installed on one side of the vacuum chamber door 24; image 3 As shown, the top of the vacuum chamber 10 is a detachable cover plate 5; the vacuum system is connected to the vacuum chamber 10; the temperature control unit is used to heat the tensile sample 3 and measure the temperature of the tensile sample 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com