Connecting method of plastic hollow wall winding pipe joint for traction

A connection method and a technology of winding pipes, which are applied in the field of water supply and drainage, can solve the problems of pipe leakage, damage, stiffness and strength reduction, etc., and achieve the effects of uniform axial force, reducing traction force, and improving stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

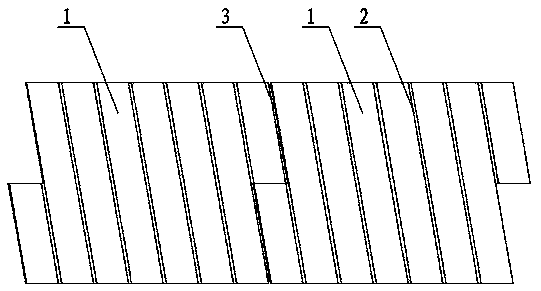

[0039] A plastic hollow-wall winding tube for traction of this patent is adopted, and a heating wire mesh 3 and a three-layer sealing sleeve 4 are adopted.

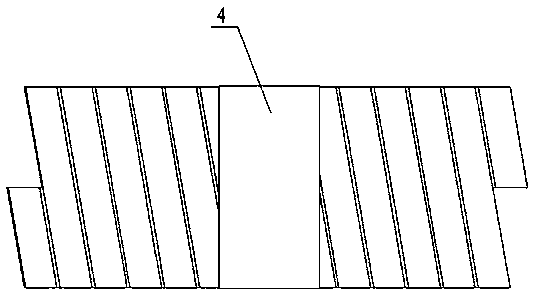

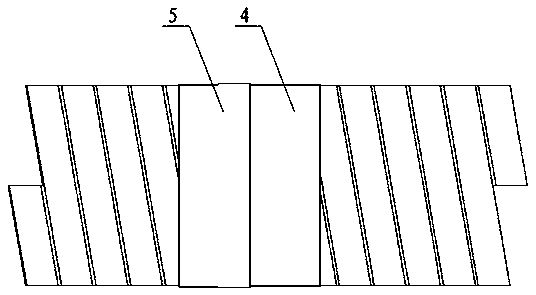

[0040] A method for connecting a plastic hollow-wall winding pipe joint for traction, comprising a plastic special-shaped square pipe 1, melted glue 2, a heating element 3, a sealing sleeve 4, and a pre-wear sleeve 5; the connection steps of the winding pipe joint are as follows:

[0041] 1) Cutting: Put the plastic hollow-wall winding tube on the bracket, and use a cutting tool to spirally cut and disconnect the winding tube along the glued joint;

[0042] 2) Clean the end face: clean the burrs on the spiral end face after cutting;

[0043] 3) Fix heating element 3: Fix and install heating element 3 on the left end surface of the spirally cut right plastic hollow wall winding pipe after cleaning;

[0044] 4) Butt-wrapped pipe joints: fix the left plastic hollow-walled winding pipe and the right plastic hollow-walled win...

Embodiment 2

[0055] A plastic hollow-wall winding tube for traction of this patent is adopted, and a heating screen 3 and a two-layer sealing sleeve 4 are adopted.

[0056] The rest are the same as above and will not be repeated.

Embodiment 3

[0058] Adopt a kind of plastic hollow-wall winding tube for traction of this patent, adopt heating wire mesh 3, one layer of sealing sleeve 4.

[0059] The rest are the same as above and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com