High-pixel photographic module and burning method for chip

The technology of a camera module and a burning method is applied in the direction of image communication, color TV parts, TV system parts, etc. It can solve the problems of small size of read-only memory, scrapping of modules, increase of cost, etc., and achieve good results. Technical advantages and technical effects, improvement of yield and production efficiency, and improvement of brightness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

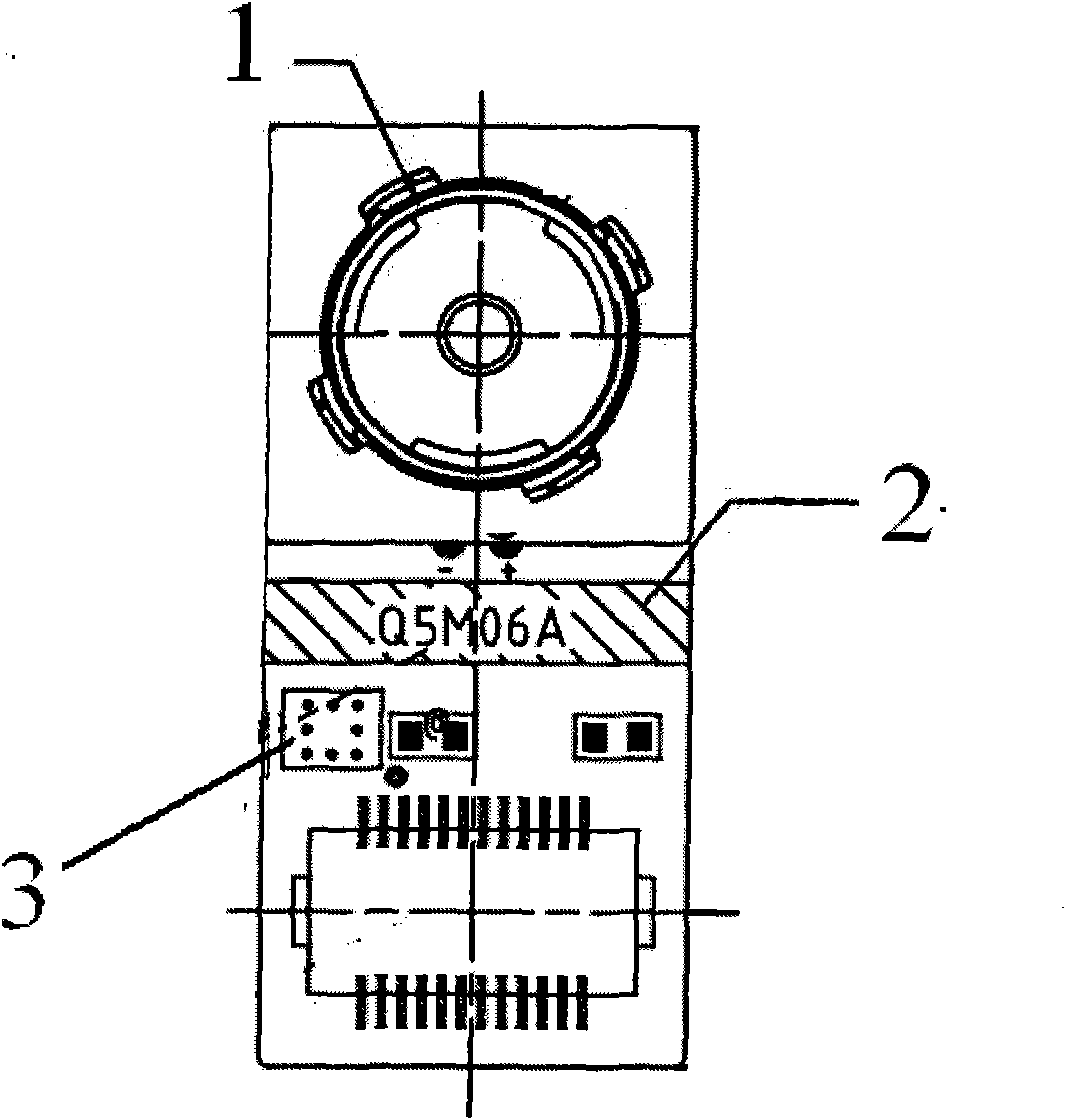

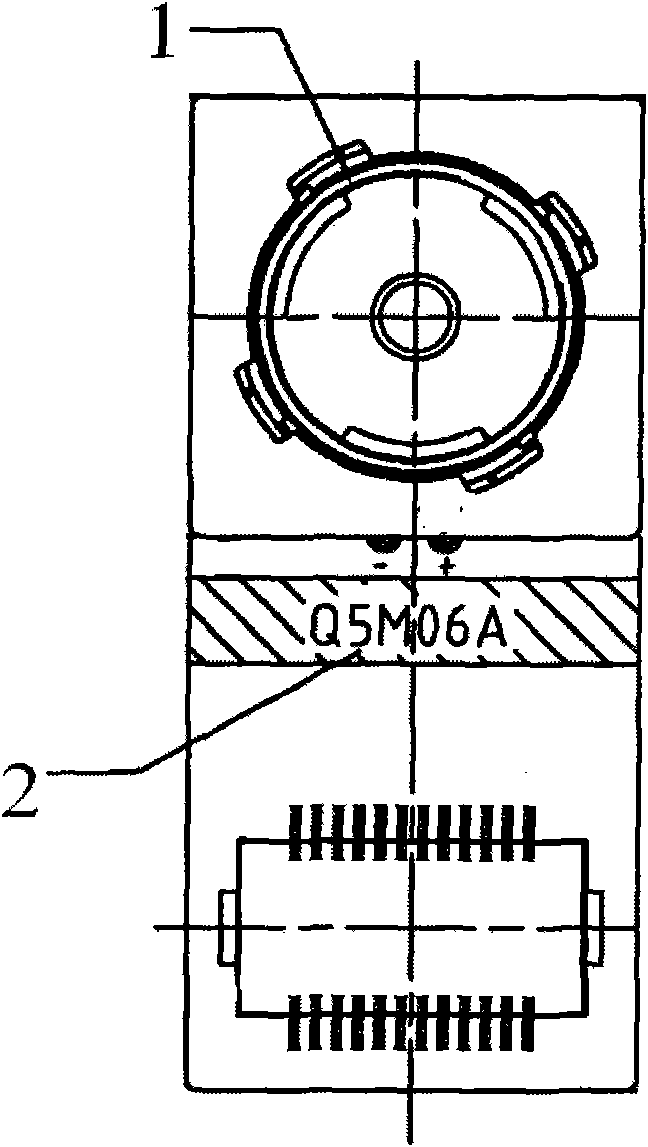

[0035] figure 2 It is a structural schematic diagram of a specific embodiment of the high-pixel camera module of the present invention.

[0036] As shown in the figure, compared with the existing design, this embodiment removes the electrically erasable programmable read-only memory (EEPROM), and adopts an integrated one-time programmable chip (OTP, not shown in the figure) The optical detection element 1 is fixed on the circuit board 4 by welding or other methods, and a black silver foil 2 is arranged below the optical detection element 1 .

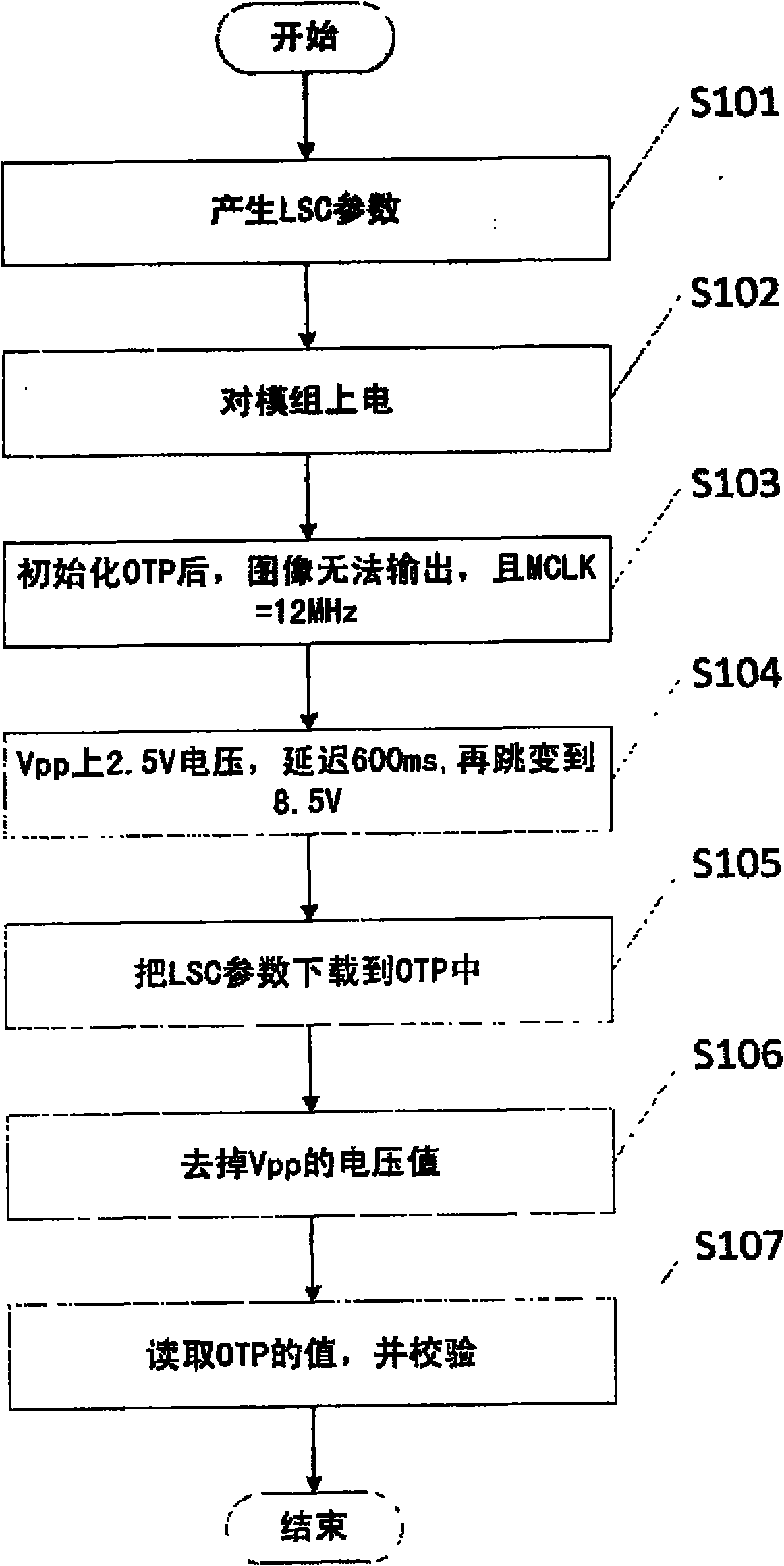

[0037] Moreover, in the one-time programmable chip integrated with the above-mentioned optical detection element, the lens conformity compensation parameter (LSC) corresponding to the photosensitive optical detection element is burned, and the reading format of the above-mentioned parameter is set in the software of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com