Lithium ion battery internal temperature monitoring method

A lithium-ion battery and internal temperature technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems that the temperature control of lithium-ion batteries cannot provide accurate information, cannot be applied in real vehicles, and has a large amount of calculation. The test method is simple and fast, the calculation method is simple and easy, and the effect of real-time monitoring is satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

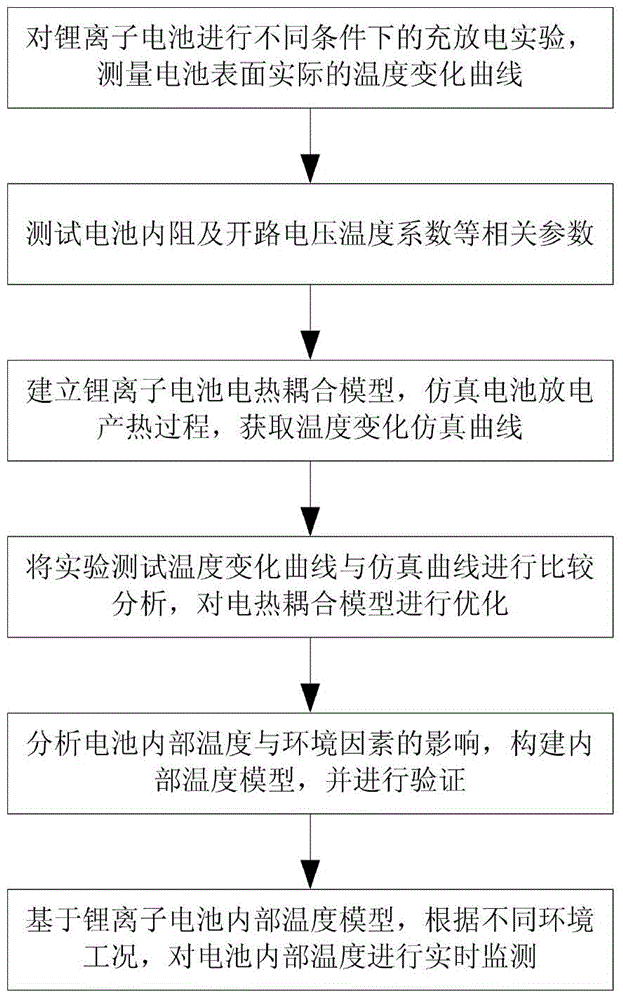

[0035] The specific embodiments of the present invention will be further described in detail below with reference to the drawings and the description of the implementation examples. The process of the method for monitoring the internal temperature of the lithium ion battery of the present invention is as follows figure 1 Shown:

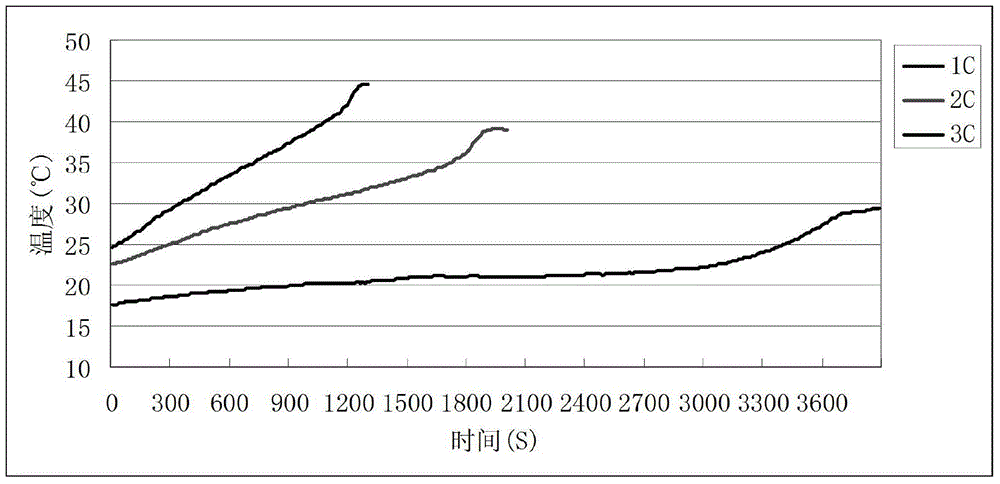

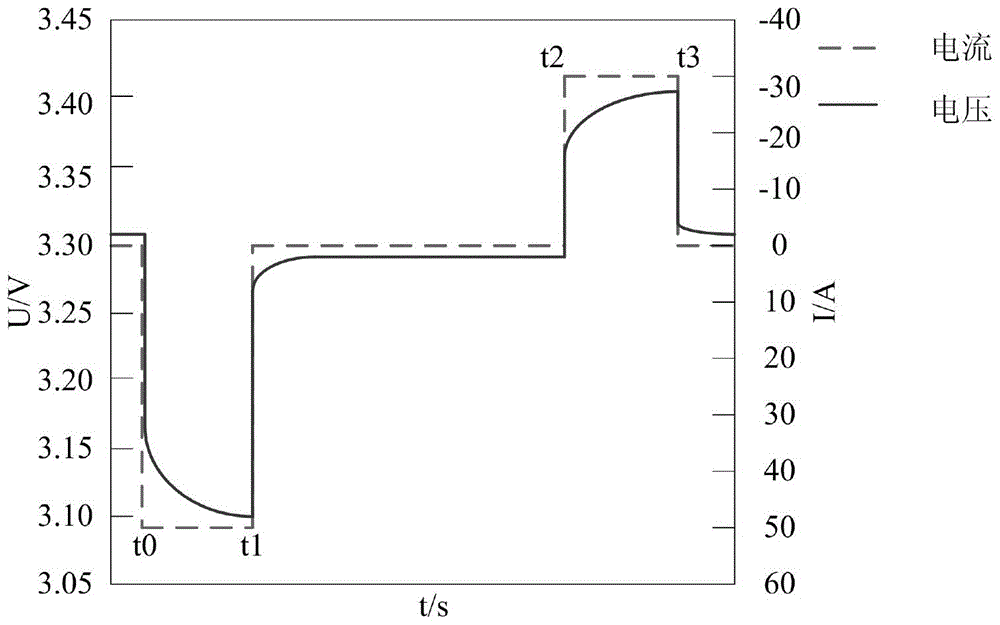

[0036] 1) First, use the charge and discharge tester to perform charge and discharge experiments under different environmental conditions (different environmental conditions including ambient temperature, different charge and discharge rates, and heat dissipation coefficient conditions) of the lithium-ion battery to be tested, and close multiple temperature sensors to the cell On the surface of the battery, measure the surface temperature change curve of the lithium ion battery during charging and discharging; the sample selected in this embodiment is a 3.2V / 20Ah lithium iron phosphate battery with a discharge cut-off voltage of 2.5V, a charge cut-off vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com