Facing type fireproofing powder paint

A powder coating and finishing technology, applied in powder coatings, fireproof coatings, polyester coatings, etc., can solve the problems of high formula cost, low flame retardant effect, high production cost, etc., and achieve low formula cost and production and processing costs , Good flame retardant and fireproof effect, good effect of anti-aging and attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further illustrate the scheme and effect of the present invention below in conjunction with embodiment.

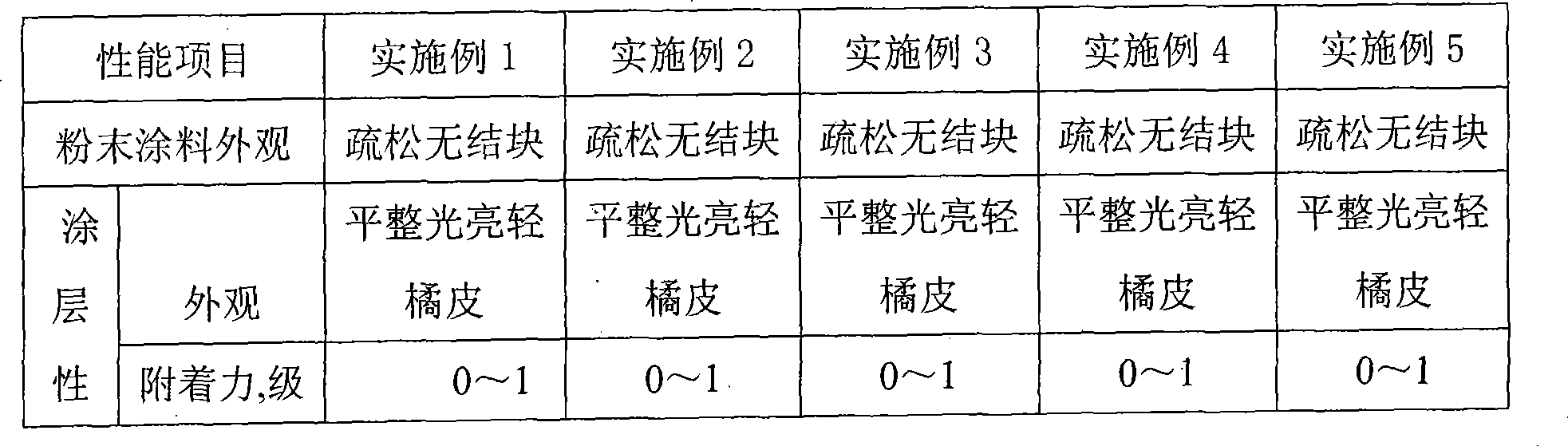

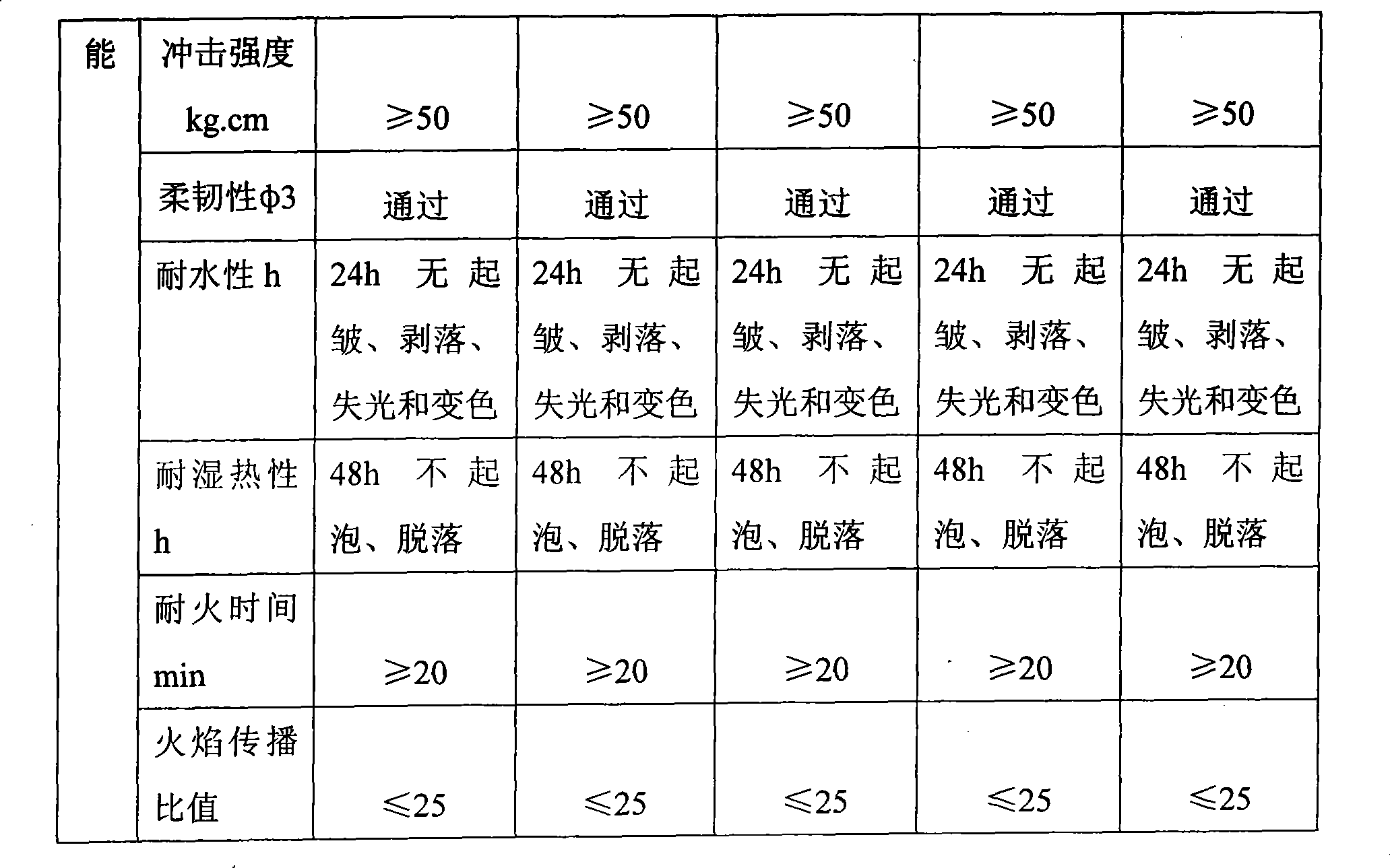

[0025] The amount of raw materials used in each embodiment of the facing type fireproof powder coating of the present invention is shown in Table 1 by weight percentage, and the finished product is obtained by a conventional powder coating production process. The main properties of its corresponding fireproof coating after coating are shown in Table 2.

[0026] Raw material name and manufacturer in the embodiment are as follows:

[0027] E—12: Zhejiang Nanhai Pharmaceutical Group;

[0028] JECP-03B: Changshu Jiafa Chemical Co., Ltd.;

[0029] P5127: DSM Coating Resins, Inc.

[0030] EP—16, EP—153: Wuxi Diaisheng Epoxy Co., Ltd.

[0031] Ammonium polyphosphate APP(II), n>1000: Shandong Shian Chemical Co., Ltd.;

[0032] Others are commercially available.

[0033] Table 1 Example formula of fireproof powder coating of the present invention

[0034] Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com