Disposable double stage filtering magnetic machine oil filter

An oil filter and stage filtration technology, used in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc. Low cost, simple structure, and the effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

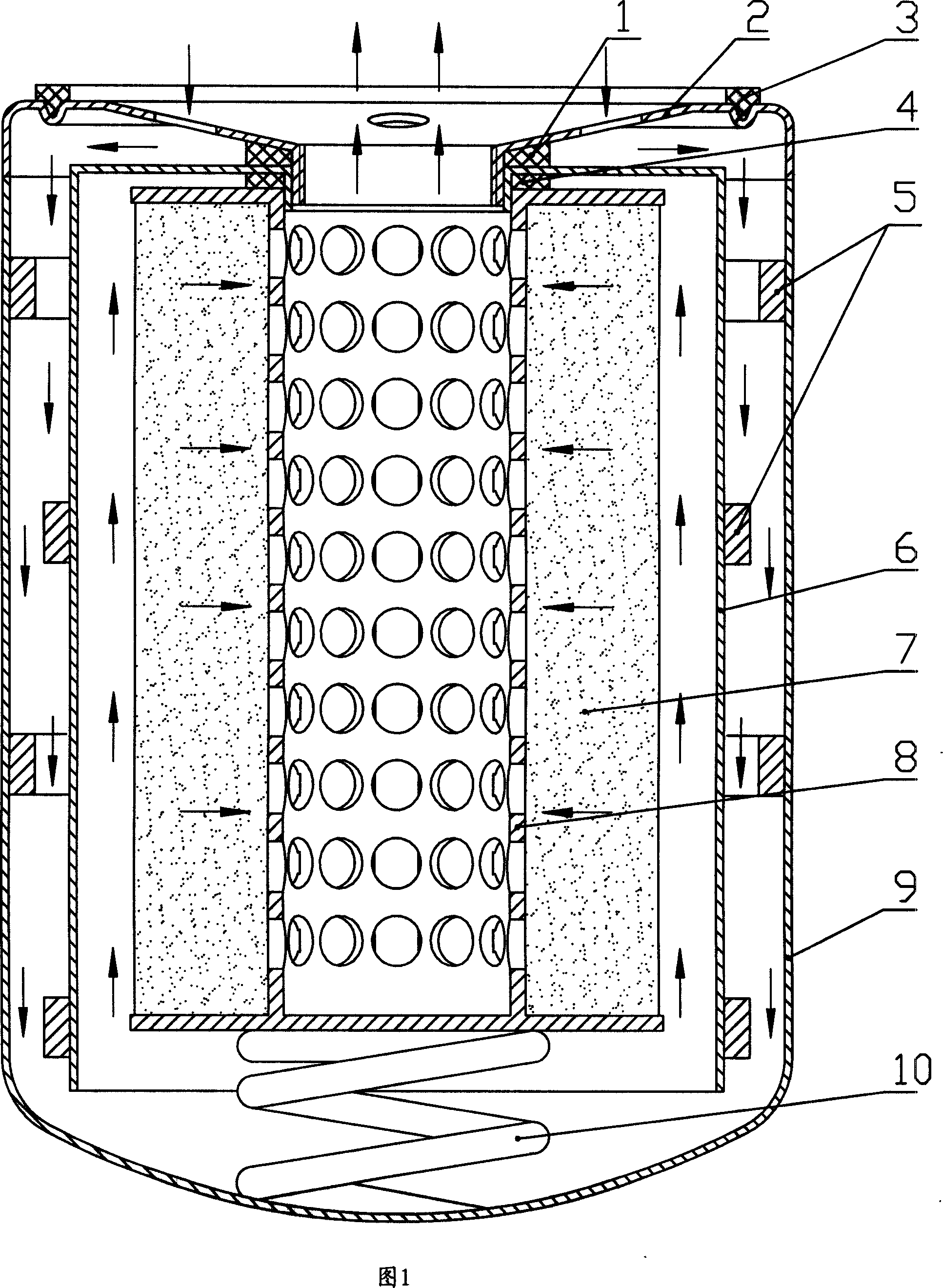

[0027] Embodiment 1: Referring to Fig. 1, the disposable two-stage filter magnetic oil filter in the figure includes a barrel-shaped housing 9, an upper cover 2, a combined ring magnet 5, a support spring 10, a filter element 7, and a seal, and the filter element 7 is located at In the housing 9, the upper cover 2 is airtightly connected with the housing 9, the upper cover 2 is provided with oil inlet and outlet ports, the filter element 7 is provided with a filter element support 8 matching its shape, and the filter element support 8 is provided with There are evenly distributed oil holes, the lower end surface of the filter element support 8 is closed, and the upper end surface is provided with an oil outlet matching the oil outlet of the upper cover 2, the support spring 10 is located at the lower part of the filter element support frame 8, and the filter element 7 is provided with a Isolation cylinder 6, the exterior of the upper end of the isolation cylinder 6 is kept seal...

Embodiment 2

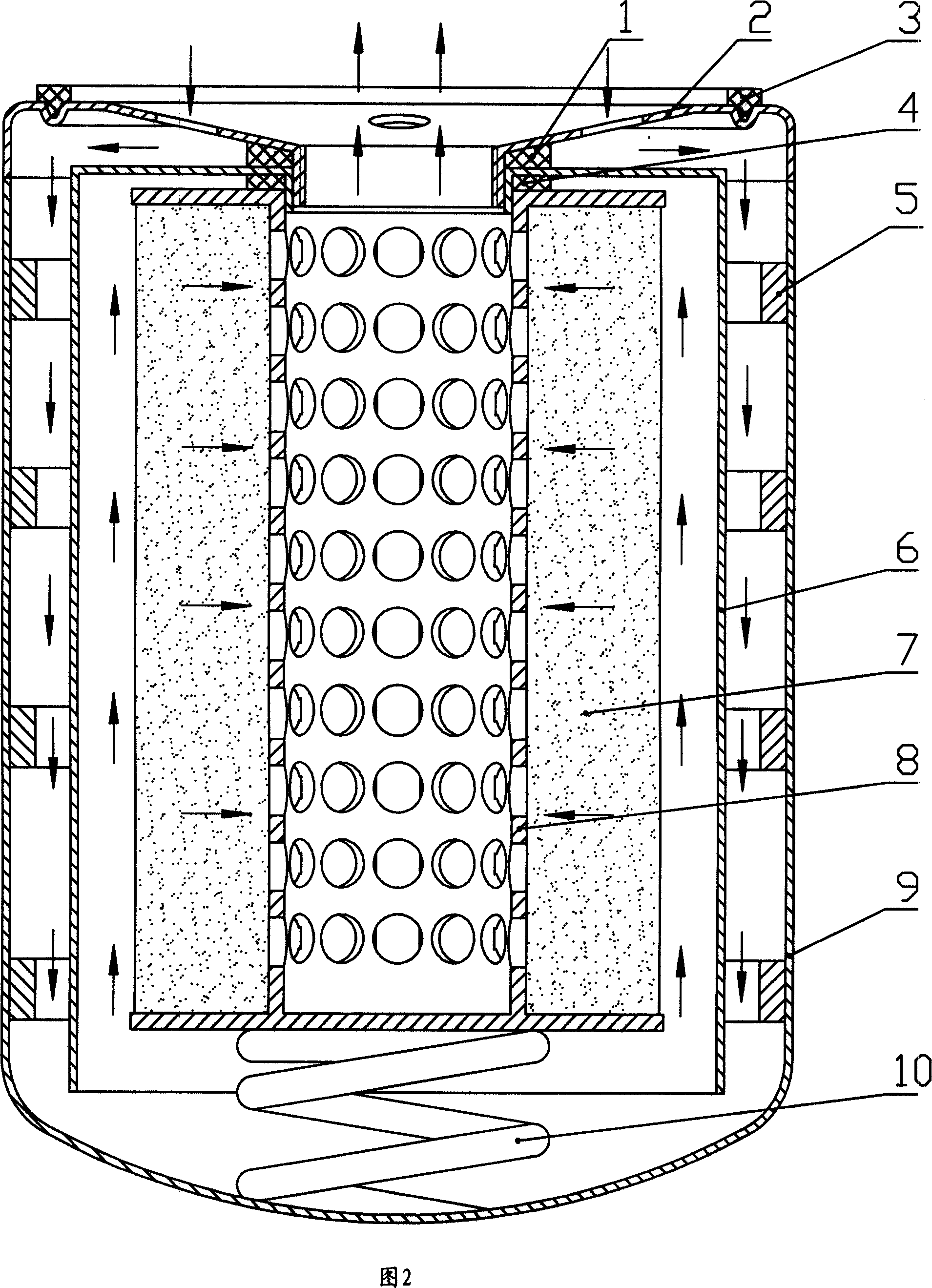

[0029] Embodiment 2: Referring to Fig. 2, Embodiment 2 is basically the same as Embodiment 1. The same symbols in the figure represent the same meaning, and the same parts will not be repeated. The difference is that in Embodiment 2, only the inner wall of the housing 9 is provided with a Matching combination ring magnet5.

Embodiment 3

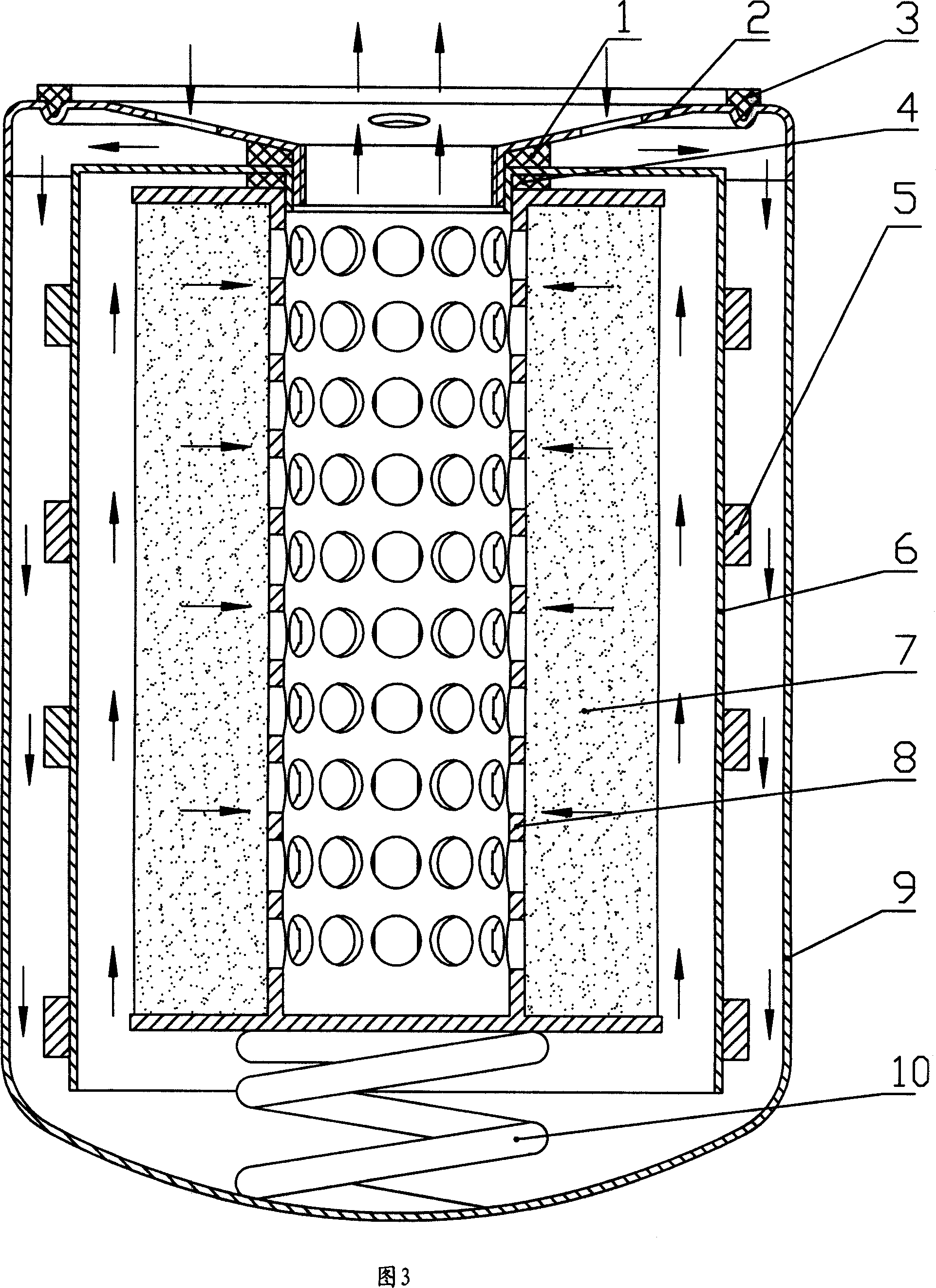

[0030] Embodiment 3: Referring to Fig. 3, Embodiment 3 is basically the same as Embodiment 1. In the figure, the same representative meanings are the same, and the similarities will not be repeated. The difference is that only the outer wall of the cylinder 6 is isolated in Embodiment 3 A combined ring magnet 5 matching it is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com