Compound biological enzyme degumming method for ramie

A degumming method and biological enzyme technology, which are applied in the fields of plant raw materials, textiles and papermaking, fiber processing, etc., can solve the problems of difficult process control, unstable degumming effect, harsh preparation conditions, etc. The effect of improving spinnability and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

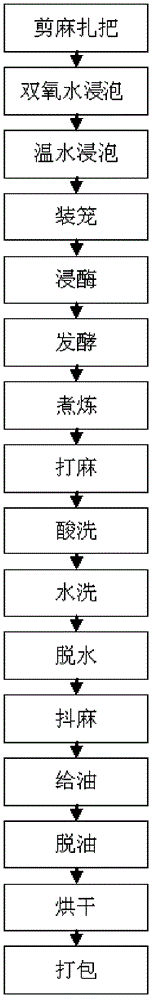

Method used

Image

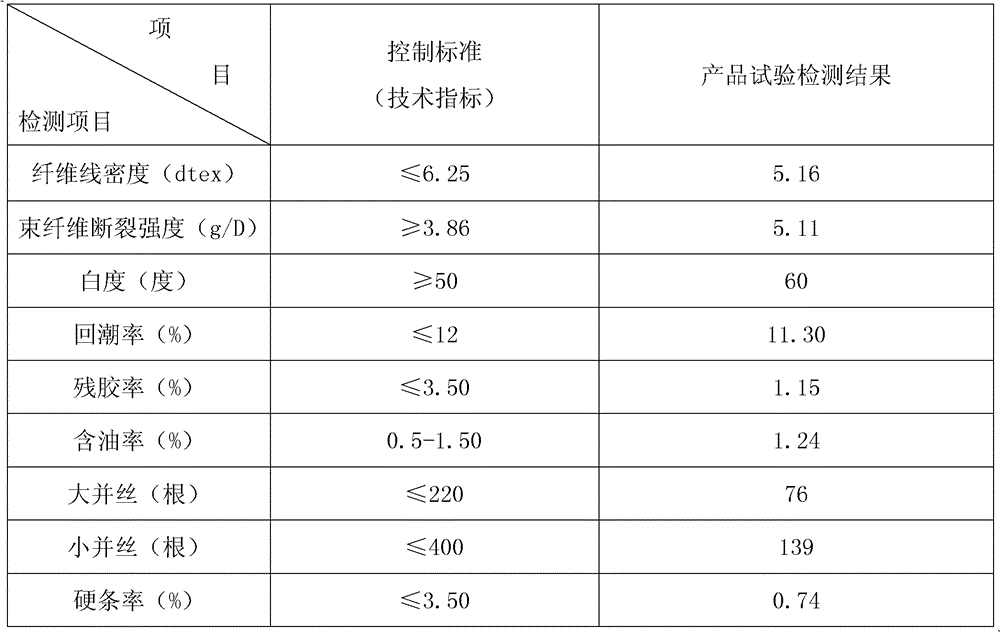

Examples

Embodiment 1

[0037] Embodiment 1: ramie composite biological enzyme degumming method, comprises the following steps:

[0038] (1) Cutting hemp and binding: untie the hemp knots in the original hemp, and pick out the dry and short hemp, then straighten the original hemp, distinguish the head and tail, and tie it into a hemp handle of 2.5-3.5 catties;

[0039] (2) Soaking in hydrogen peroxide: Put 4.5-5.5 kg of hydrogen peroxide, 0.9-1.1 kg of deoxygenase and 2.8-3.2 tons of clear water into the cement pool, and keep the water temperature at 18-22 °C, put the tied hemp handle into the pool for 13- 18 hours, making ramie return to the character when harvesting;

[0040] (3) Soaking in warm water: put the ramie soaked in hydrogen peroxide into an iron box, put in clear water, and heat up to 55-65°C for soaking to make the ramie fully swell;

[0041] (4) Caging: the soaked ramie is loosely hung on the hemp cage, and the weight of every cage is 480-520 kg;

[0042] (5) Enzyme soaking: configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com