UV curing gloss oil with excellent explosion-proof performance and preparation method thereof

An anti-explosion line, an excellent technology, applied in the field of UV curing varnish and its preparation, can solve the problems of high brittleness of the coating film, easy bursting of the paper, and failure to play, etc., to achieve improved yellowing resistance, excellent anti-violence line performance, and storage stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

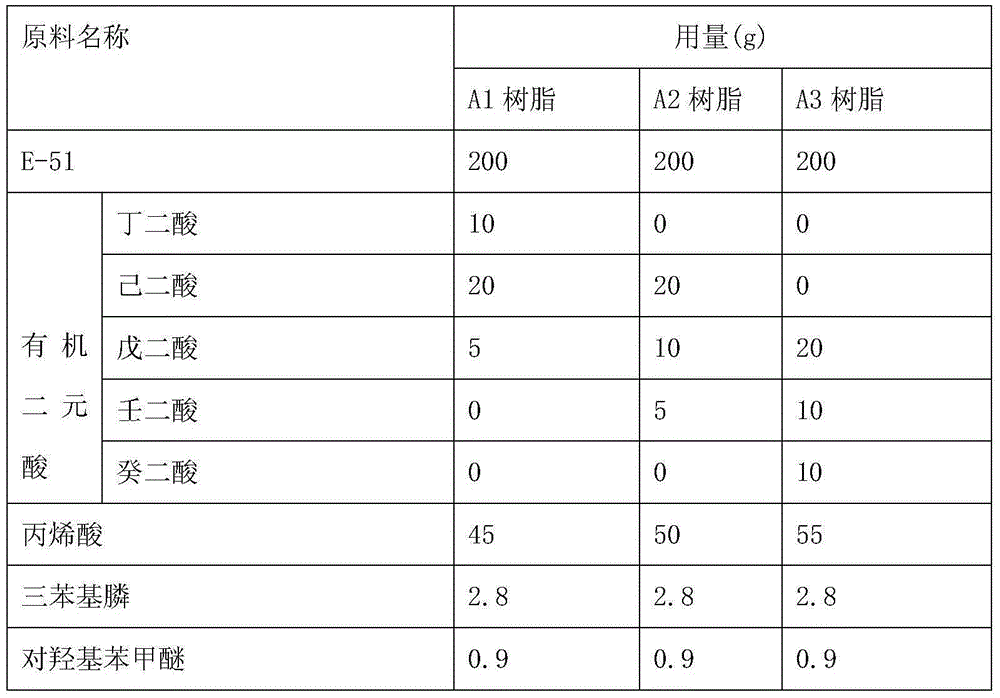

Examples

Embodiment 1

[0026] Take 100g of A1 resin, add 0.4g of defoamer, 20g of tripropylene glycol diacrylate, 15g of 1,6-hexanediol diacrylate, stir well, then add 8g of benzophenone, 2g of 1-hydroxy-cyclohexylbenzene Ketone and 8g of active amine were stirred at high speed, and finally 0.6g of leveling agent was added to obtain UV-curable varnish.

Embodiment 2

[0028] Take 100g of A2 resin, add 0.4g of defoamer, 20g of tripropylene glycol diacrylate, 15g of 1,6-hexanediol diacrylate, stir well, add 8g of benzophenone, 2g of 1-hydroxy-cyclohexylbenzene Ketone and 8g of active amine were stirred at high speed, and finally 0.6g of leveling agent was added to obtain UV-curable varnish.

Embodiment 3

[0030] Take 100g of A3 resin, add 0.4g of defoamer, 20g of tripropylene glycol diacrylate, 15g of 1,6-hexanediol diacrylate, stir evenly, add 8g of benzophenone, 2g of 1-hydroxy-cyclohexylbenzene Ketone and 8g of active amine were stirred at high speed, and finally 0.6g of leveling agent was added to obtain UV-curable varnish.

[0031] Properties of UV Curable Varnish

[0032] Use the UV-curable varnish prepared in Examples 1-3 respectively, draw and coat the paper printed with ink with a 4 μm wire bar, and cure with UV light. The performance inspection and evaluation of the light film are carried out according to the following methods. The performance is shown in Table 2 .

[0033] Table 2 UV varnish dry film properties

[0034] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com