Waterborne polyester resin coating and preparation method thereof

A water-based polyester resin and coating technology, applied in polyester coatings, coatings, etc., to achieve high environmental protection, economic cost disclosure, and high fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

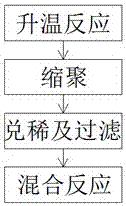

[0023] Such as figure 1 As shown, it is the waterborne polyester resin coating described in this embodiment, including: polyhydric alcohol, polybasic acid, catalyst 6%, curing agent 2%, pigment 4%, filler 2%, cosolvent 12% and water 40%;

[0024] Described polyhydric alcohol comprises trimethylolpropane 8%, neopentyl glycol 12%, ethylene glycol 6%, propylene glycol 8%, and described polybasic acid comprises purified terephthalic acid 5%, isophthalic acid 12%, 6% phthalic acid, 10% trimellitic anhydride, 6% hexahydrophthalic acid, 10% maleic anhydride, 5% adipic acid;

[0025] The water-based polyester resin coating also includes 0.1% p-methoxyphenol, 6% ethylene glycol monobutyl ether, 8% dimethylethanolamine, and 60% deionized water.

[0026] More specifically, the preparation method of described waterborne polyester resin coating is as follows:

[0027] (1) Temperature rise reaction: In the first reaction kettle, polyhydric alcohol, polybasic acid, p-methoxyphenol, ethylen...

specific Embodiment 2

[0034] The water-based polyester resin coating of the present invention comprises: polyhydric alcohol, polybasic acid, catalyst 7%, curing agent 4%, pigment 6%, filler 4%, cosolvent 15% and water 60%;

[0035] Described polyhydric alcohol comprises trimethylolpropane 10%, neopentyl glycol 18%, ethylene glycol 9%, propylene glycol 10%, and described polybasic acid comprises purified terephthalic acid 10%, isophthalic acid 18%, 9% phthalic acid, 14% trimellitic anhydride, 9% hexahydrophthalic acid, 15% maleic anhydride, 8% adipic acid;

[0036] The water-based polyester resin coating also includes 0.2% p-methoxyphenol, 15% ethylene glycol monobutyl ether, 12% dimethylethanolamine, and 80% deionized water.

[0037] More specifically, the preparation method of described waterborne polyester resin coating is as follows:

[0038] (1) Temperature rise reaction: In the first reaction kettle, polyhydric alcohol, polybasic acid, p-methoxyphenol, ethylene glycol monobutyl ether, dimethy...

specific Embodiment 3

[0045] The water-based polyester resin coating of the present invention comprises: polyhydric alcohol, polybasic acid, catalyst 8%, curing agent 6%, pigment 8%, filler 6%, cosolvent 18% and water 80%;

[0046] Described polyhydric alcohol comprises trimethylolpropane 12%, neopentyl glycol 24%, ethylene glycol 12%, propylene glycol 12%, and described polybasic acid comprises purified terephthalic acid 15%, isophthalic acid 24%, 12% phthalic acid, 18% trimellitic anhydride, 12% hexahydrophthalic acid, 20% maleic anhydride, 10% adipic acid;

[0047] The water-based polyester resin coating also includes 0.3% p-methoxyphenol, 24% ethylene glycol monobutyl ether, 16% dimethylethanolamine, and 100% deionized water.

[0048] More specifically, the preparation method of described waterborne polyester resin coating is as follows:

[0049] (1) Temperature rise reaction: In the first reaction kettle, polyhydric alcohol, polybasic acid, p-methoxyphenol, ethylene glycol monobutyl ether, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com