Waterborne UV epoxy acrylic resin and preparation method thereof

A technology of epoxy acrylic and epoxy resin, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of poor substrate adhesion, poor stability, poor hydrophilicity, etc., and achieve fast UV curing speed and good stability , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

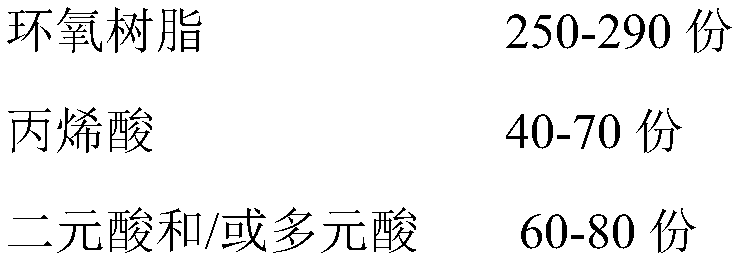

[0034] A water-based UV epoxy acrylic resin, in parts by mass, comprises the following components:

[0035]

[0036] The epoxy value of described E51 epoxy resin is 0.50.

[0037] A preparation method of water-based UV epoxy acrylic resin, comprising the following steps:

[0038] (1) Weigh each component according to the formula amount, add E51 epoxy resin and acrylic acid into the three-necked reaction flask, stir evenly, then add 4-methoxyphenol and N,N-dimethylbenzylamine, and then add React at 70°C for 0.5 hours, then react at 90-110°C for 1 hour, then add methylene succinic acid, keep warm at 90°C until the acid value is ≤83mgKOH / g, cool down to below 80°C, add ethanol, and continue stirring Become a homogeneous transparent liquid, set aside;

[0039] (2) Add water and N,N-dimethylethanolamine into the beaker, stir evenly, then slowly pour the homogeneous transparent liquid synthesized in step (1) into the beaker under stirring, and stir evenly to obtain the obtained...

Embodiment 2

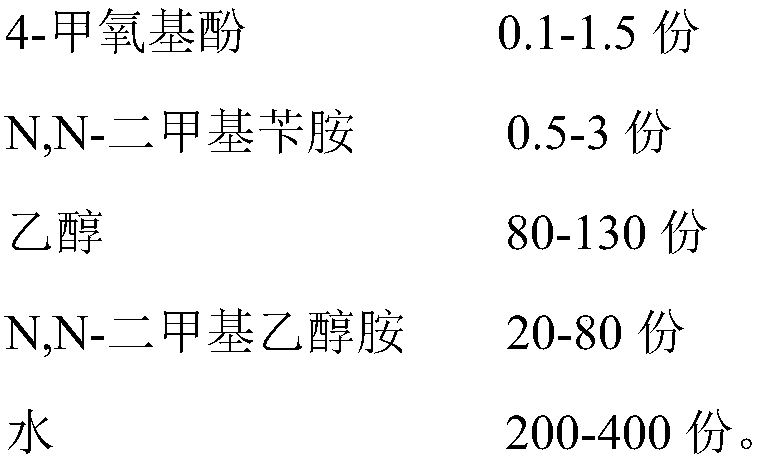

[0042] Preferably, a water-based UV epoxy acrylic resin, in parts by mass, comprises the following components:

[0043]

[0044] The epoxy value of the E51 epoxy resin is 0.52.

[0045] A preparation method of water-based UV epoxy acrylic resin, comprising the following steps:

[0046] (1) Weigh each component according to the formula amount, add E51 epoxy resin and acrylic acid into the three-necked reaction flask, stir evenly, then add 4-methoxyphenol and N,N-dimethylbenzylamine, and then add React at 80°C for 1.5 hours, then react at 95°C for 2.5 hours, then add citric acid, keep warm at 100°C until the acid value is ≤83mgKOH / g, cool down to below 80°C, add ethanol, and continue stirring to form a homogeneous transparent liquid ,spare;

[0047] (2) Add water and N,N-dimethylethanolamine into the beaker, stir evenly, then slowly pour the homogeneous transparent liquid synthesized in step (1) into the beaker under stirring, and stir evenly to obtain the obtained The wat...

Embodiment 3

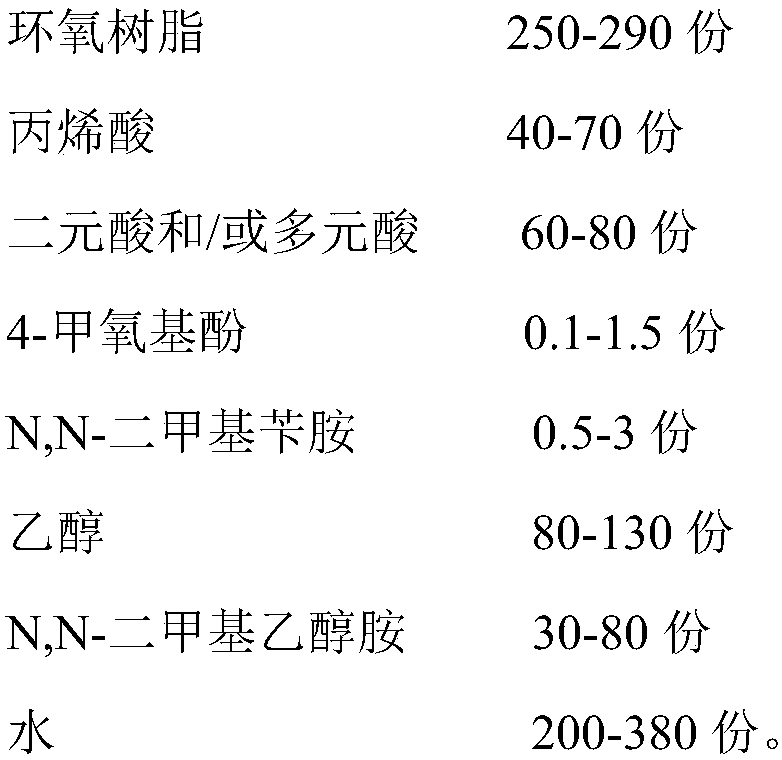

[0050] A water-based UV epoxy acrylic resin, in parts by mass, comprises the following components:

[0051]

[0052]

[0053] The epoxy value of the E51 epoxy resin is 0.53.

[0054] A preparation method of water-based UV epoxy acrylic resin, comprising the following steps:

[0055] (1) Weigh each component according to the formula amount, add E51 epoxy resin and acrylic acid into the three-necked reaction flask, stir evenly, then add 4-methoxyphenol and N,N-dimethylbenzylamine, and then add React at 85°C for 1 hour, then react at 98°C for 2 hours, then add methylene succinic acid, keep warm at 98°C until the acid value is ≤ 83 mgKOH / g, cool down to below 80°C, add ethanol, and continue to stir to form a homogeneous mixture. Phase transparent liquid, spare;

[0056] (2) Add deionized water and N,N-dimethylethanolamine into the beaker, stir evenly, then slowly pour the homogeneous transparent liquid synthesized in step (1) into the beaker under stirring, and stir evenly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com