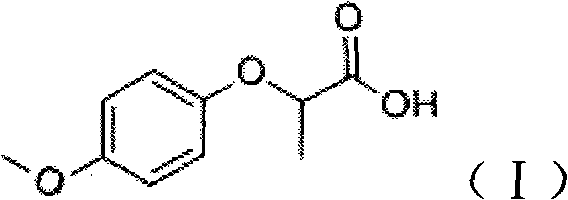

Industrial method for synthesizing 2-(4-methoxyphenoxy)-propionic acid through phase transfer

A technology of methoxyphenoxy and phase transfer catalysts, applied in the field of food science, can solve the problems of high production cost, low product purity, high reaction temperature, etc., and achieve the effect of shortening the reaction time, shortening the reaction time and improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

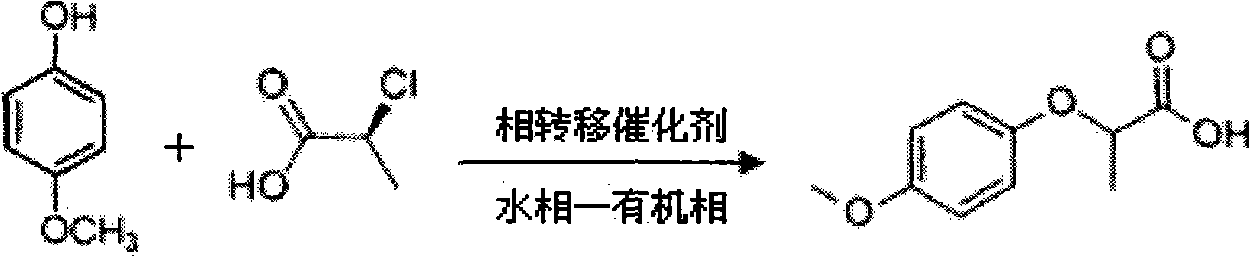

Method used

Image

Examples

Embodiment 1

[0031] (1) Add p-hydroxyanisole 10kg, sodium hydroxide 11kg, phase transfer catalyst tetrabutylammonium bromide 0.4kg, water 150L respectively in the reactor, stir and mix under normal temperature and pressure, stirring speed 150r / min, After reacting for 15 minutes, p-hydroxyanisole was converted into sodium p-methoxyphenate to obtain mixed material liquid A;

[0032] (2) In the mixture liquid A, add 15kg of 2-chloropropionic acid, 150L of ether, the reaction temperature is 40°C, the reaction pressure is 3MPa, the stirring speed is 150r / min, and the reaction is 1.5h to obtain the product 2-(4 -methoxyphenoxy)-propionic acid;

[0033] (3) The reaction solution after the reaction is adjusted to be acidic with 20% HCl solution, and the water phase and the organic phase ether are separated by standing, and the 2-(4-methoxyphenoxy)-sodium propionate in the water phase is converted 2-(4-methoxyphenoxy)-propionic acid enters the organic phase with diethyl ether, and the organic phas...

Embodiment 2

[0036] (1) Add 10kg of p-hydroxyanisole, 20kg of sodium hydroxide, 0.6kg of phase transfer catalyst cyclodextrin, and 200L of water into the reaction kettle respectively, stir and mix at normal temperature and pressure, the stirring speed is 200r / min, and react for 10min. Convert p-hydroxyanisole to sodium p-methoxyphenate to obtain mixed material liquid A;

[0037] (2) In the mixture liquid A, add 15kg of 2-chloropropionic acid, 200L of n-hexane, raise the reaction temperature to 45°C, the pressure is 2MPa, the stirring speed is 200r / min, and react for 1h to obtain the product 2-(4 -methoxyphenoxy)-propionic acid;

[0038] (3) The reaction solution after the reaction was treated with 15% H 2 SO 4The solution is adjusted to be acidic, and the aqueous phase and the organic phase n-hexane are separated by standing, and the 2-(4-methoxyphenoxy)-sodium propionate in the aqueous phase is converted into 2-(4-methoxyphenoxy )-propionic acid enters the organic phase, and separates ...

Embodiment 3

[0041] (1) Add 10kg of p-hydroxyanisole, 25kg of sodium hydroxide, 0.8kg of phase transfer catalyst cyclodextrin, and 150L of water into the reaction kettle respectively, stir and mix at normal temperature and pressure, the stirring speed is 200r / min, and react for 10min, Convert p-hydroxyanisole to sodium p-methoxyphenate to obtain mixed material liquid A;

[0042] (2) In the mixture liquid A, add 20 kg of 2-chloropropionic acid and 160 L of petroleum ether, raise the reaction temperature to 40 ° C, the pressure is 2 MPa, the stirring speed is 200 r / min, and react for 1 h to obtain the product 2-(4 -methoxyphenoxy)-propionic acid;

[0043] (3) The reaction solution after the reaction was treated with 10% H 2 SO 4 The solution is adjusted to be acidic, and the aqueous phase is separated from the organic phase petroleum ether, and the 2-(4-methoxyphenoxy)-sodium propionate in the aqueous phase is converted into 2-(4-methoxyphenoxy )-propionic acid enters the organic phase, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com