Optical fiber coloring ink capable of being solidified by LED and preparing method thereof

A technology for coloring inks and LED lamps, applied in inks, applications, household appliances, etc., can solve the problems of high noise and short life of curing lamps, and achieve the effects of low coloring noise, saving coloring power, and fast coloring speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

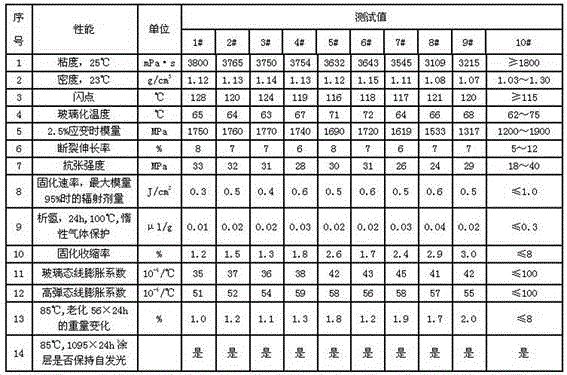

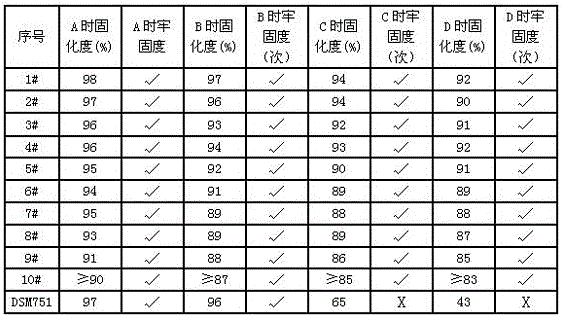

Examples

Embodiment 1

[0051] An optical fiber coloring ink that can be cured by an LED lamp is characterized in that the ink is made of the following raw materials in parts by weight:

[0052] Epoxy acrylic resin: 60 parts;

[0053] Isopropyl tris (dioctyl pyrophosphate acyloxy) titanate: 20 parts;

[0054] Commercially available polyacrylic acid model 845: 7 parts;

[0055] 3-Aminopropyltriethoxysilane: 8 parts;

[0056] Nitrocellulose: 6 parts;

[0057] Isopropanol: 16 parts;

[0058] 2-isopropylthioxanthone: 1.5 parts;

[0059] Sodium benzenesulfonate: 1.5 parts;

[0060] Benzophenone: 1.5 parts;

[0061] Oleic acid: 1 part;

[0062] Composite photosensitizer: 7.5 parts;

[0063] P-methoxyphenol: 1.5 parts;

[0064] Defoamer of commercially available model BYK088: 0.75 parts;

[0065] Commercially available leveling agent BYK344: 0.75 parts;

[0066] Wherein, the composite photosensitizer is obtained by uniformly mixing the commercially available photosensitizer model 184, the commercia...

Embodiment 2

[0068] An optical fiber coloring ink that can be cured by an LED lamp is characterized in that the ink is made of the following raw materials in parts by weight:

[0069] Epoxy acrylic resin: 60 parts;

[0070] Isopropyl tris (dioctyl pyrophosphate acyloxy) titanate: 20 parts;

[0071] Commercially available polyacrylic acid model is 820: 7 parts;

[0072] 3-Aminopropyltriethoxysilane: 8 parts;

[0073] Nitrocellulose: 6 parts;

[0074] Isopropanol: 16 parts;

[0075] 2-isopropylthioxanthone: 1.5 parts;

[0076] Sodium benzenesulfonate: 1.5 parts;

[0077] Benzophenone: 1.5 parts;

[0078] Oleic acid: 1 part;

[0079] Composite photosensitizer: 7.5 parts;

[0080] P-methoxyphenol: 1.5 parts;

[0081] Defoamer of commercially available model BYK088: 0.75 parts;

[0082] Commercially available leveling agent BYK344: 0.75 parts;

[0083] Wherein, the composite photosensitizer is obtained by uniformly mixing the commercially available photosensitizer model 184, the comm...

Embodiment 3

[0085] An optical fiber coloring ink that can be cured by an LED lamp is characterized in that the ink is made of the following raw materials in parts by weight:

[0086] Epoxy acrylic resin: 60 parts;

[0087] Isopropyl tris (dioctyl pyrophosphate acyloxy) titanate: 20 parts;

[0088] Commercially available polyacrylic acid model 805: 7 parts;

[0089] 3-Aminopropyltriethoxysilane: 8 parts;

[0090] Nitrocellulose: 6 parts;

[0091] Isopropanol: 16 parts;

[0092] 2-isopropylthioxanthone: 1.5 parts;

[0093] Sodium benzenesulfonate: 1.5 parts;

[0094] Benzophenone: 1.5 parts;

[0095] Oleic acid: 1 part;

[0096] Composite photosensitizer: 7.5 parts;

[0097] P-methoxyphenol: 1.5 parts;

[0098] Defoamer of commercially available model BYK088: 0.75 parts;

[0099] Commercially available leveling agent BYK344: 0.75 parts;

[0100] Wherein, the composite photosensitizer is obtained by uniformly mixing the commercially available photosensitizer model 184, the commerc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com