Method for hydrothermal synthesis of nickel hydroxide hierarchical structure microspheres assembled by nano-sheets

A nickel hydroxide, hierarchical structure technology, applied in nickel oxide/nickel hydroxide, nanotechnology and other directions, can solve the problems of complex process flow, high reaction temperature, large energy consumption, etc., achieve good application prospects, good repeatability, The effect of a large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Dissolve 0.11 g of nickel acetate in 25 ml of distilled water;

[0030] (2) Add 0.11 g of sodium polystyrene sulfonate aqueous solution (20 wt%) to the nickel acetate solution obtained in (1), and stir evenly to obtain a homogeneous system;

[0031] (3) Transfer the mixed system obtained in (2) to a polytetrafluoroethylene-lined autoclave, keep the temperature at 170 °C for 24 h, and then cool to room temperature;

[0032] (4) Centrifuge the reaction mixture with a high-speed centrifuge, remove the supernatant, wash the precipitate repeatedly with distilled water, and then wash with 95% ethanol or absolute ethanol until the clear liquid is colorless, and collect the product after drying.

Embodiment 2

[0034] (1) Dissolve 0.11g of nickel acetate in 25mL of distilled water;

[0035] (2) Add 0.11 g of sodium polystyrene sulfonate aqueous solution (20 wt%) to the nickel acetate solution obtained in (1), and stir evenly to obtain a homogeneous system;

[0036] (3) Transfer the mixed system obtained in (2) to a polytetrafluoroethylene-lined autoclave, keep the temperature at 140 °C for 24 h, and then cool to room temperature;

[0037] (4) Centrifuge the reaction mixture with a high-speed centrifuge, remove the supernatant, wash the precipitate repeatedly with distilled water, and then wash with 95% ethanol or absolute ethanol until the clear liquid is colorless, and collect the product after drying.

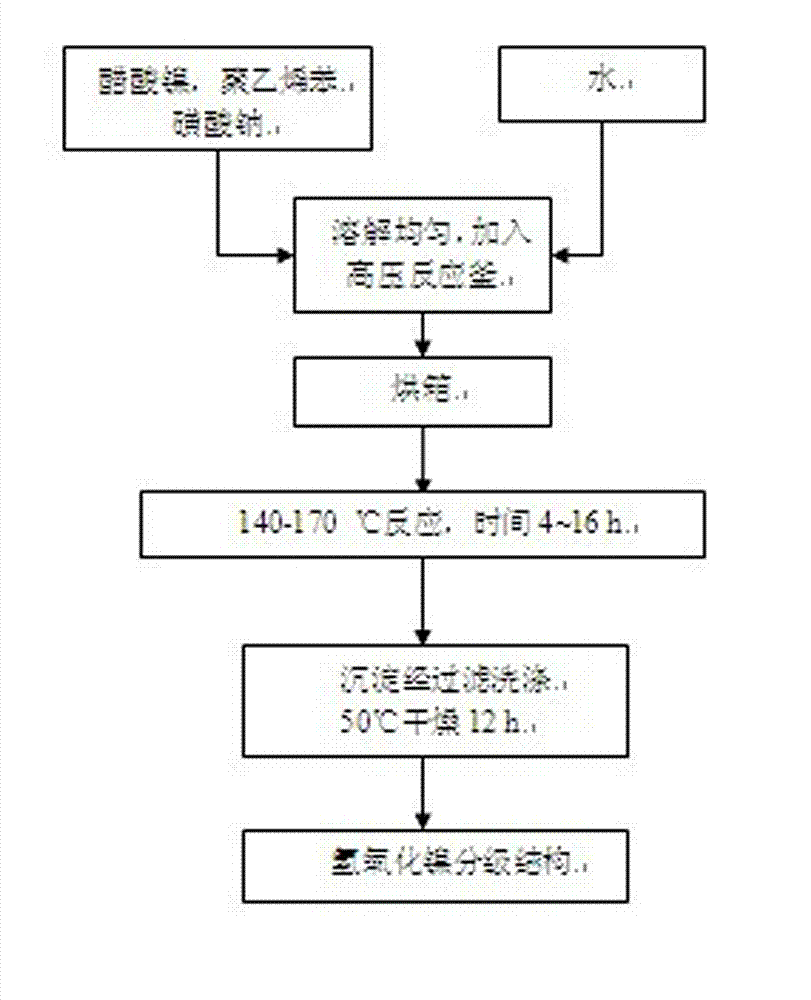

[0038] figure 1 It is a schematic diagram of the process flow of the present invention.

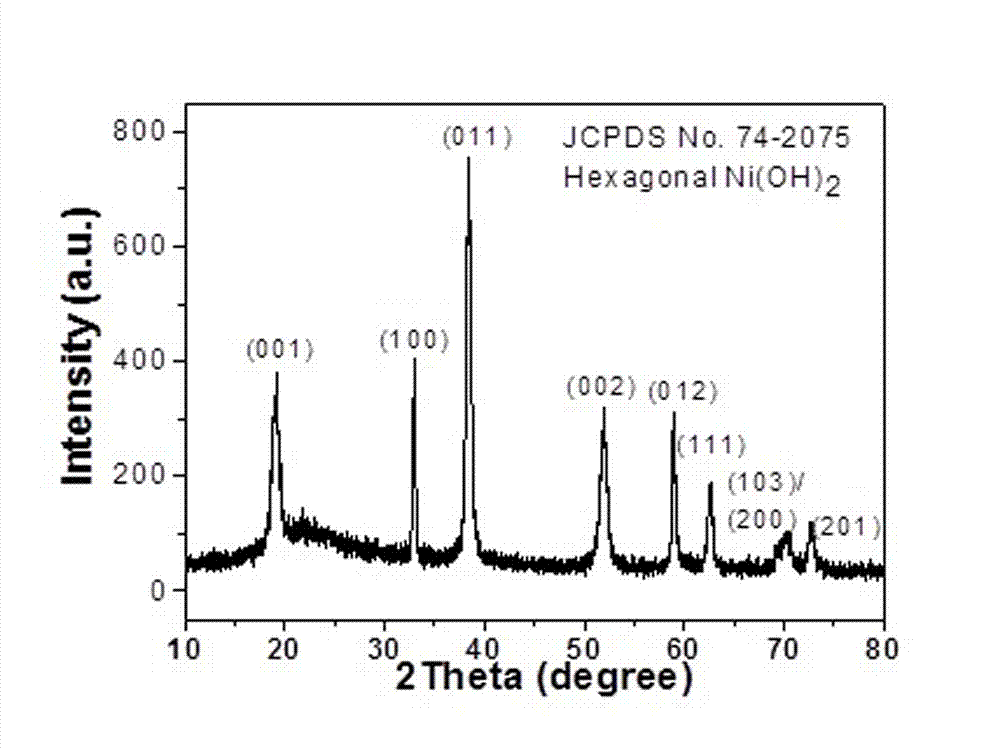

[0039] figure 2 Ni(OH) prepared for Example 1 2 The X-ray diffraction (XRD) pattern of the hierarchical structure material, where the abscissa is the diffraction angle (2 θ ), in degre...

Embodiment 3

[0043] (1) Dissolve 0.11g nickel acetate in 25 ml distilled water;

[0044] (2) Add 0.22 g of sodium polystyrene sulfonate aqueous solution (20 wt%) to the nickel acetate solution obtained in (1), and stir evenly to obtain a homogeneous system;

[0045] (3) Transfer the mixed system obtained in (2) to a polytetrafluoroethylene-lined autoclave, keep the temperature at 170°C for 24 h, and then cool to room temperature;

[0046] (4) Centrifuge the reaction mixture with a high-speed centrifuge, remove the supernatant, wash the precipitate repeatedly with distilled water, and then wash with 95% ethanol or absolute ethanol until the clear liquid is colorless, and collect the product after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com