Coating liquid, organic-inorganic hybrid cation exchange membrane and preparation method thereof

A technology of cation exchange membrane and coating liquid, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of membrane inhomogeneity, inorganic phase separation, poor experimental repeatability, etc., and achieve excellent mechanical properties. , The effect of excellent uniformity and high diffusion dialysis performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (1) Preparation of polysilicon crosslinking agent:

[0040] In molar ratio, it is monomer A containing sodium benzenesulfonate group: monomer B containing alkoxy silicon group: solvent C: initiator D=1: (1-2.34): (38.5-87.7): ( 0.020-0.036), preferably, by molar ratio, it is monomer A containing sodium benzenesulfonate group: monomer B containing alkoxy silicon group: solvent C: initiator D=1: (1-1.5) : (46-58): (0.021-0.027) ratio relationship, monomer A, monomer B, solvent C and initiator D are mixed and reacted, and then 60-75% of solvent C is removed to prepare polysilicon Crosslinker solution. Wherein monomer A, monomer B, solvent C and initiator D have the definitions as above.

[0041] Wherein, the reaction temperature and reaction time of monomer A, monomer B, solvent C and initiator D are determined by conditions such as the selected monomer and initiator. For example, in the case that monomer A is sodium styrene sulfonate, the reaction can be carried out at...

Embodiment 1

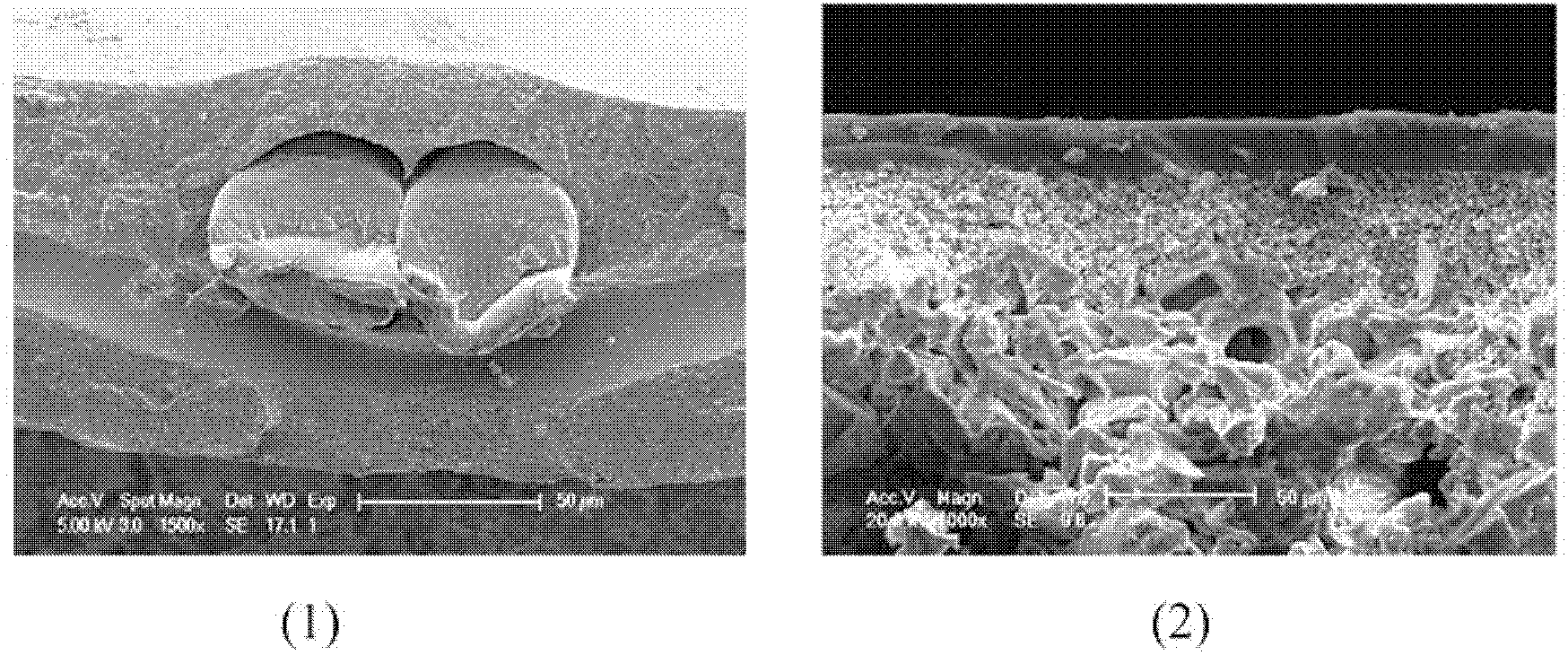

[0052] Example 1: Preparation of hybrid cation exchange membrane based on polysilicon crosslinking agent with high sodium styrene sulfonate content

[0053] Preparation of raw materials: (1) Polyvinyl alcohol (PVA, Shanghai Sinopharm Chemical Reagent Co., Ltd., polymerization degree is 1750±50) detection of raw materials: in order to test the amount of residual solvent (water and ethanol, etc.) in the PVA raw material, first take 2g PVA samples were dried at 60°C until constant weight, and the calculated weight loss ratio was 5.7%; (2) PVA dissolution: Take 42.4g of PVA raw materials, soak them in 760mL water for one day, and then dissolve them at 8°C / h under stirring conditions. The heating rate is raised to about 102°C, and kept at 102°C for 2.5 hours (h), to obtain a uniform and transparent solution, which is cooled to about 60°C for later use, and the mass concentration of the solution is 5%; (3) azobisiso Recrystallization of butyronitrile (AIBN, produced by Shanghai Sino...

Embodiment 2

[0074] Example 2: Preparation of hybrid cation exchange membrane based on polysilicon crosslinking agent with low sodium styrene sulfonate content

[0075] The preparation process of raw material is with embodiment 1, then carries out the following steps:

[0076] (1) Preparation of polysilicon crosslinking agent: Add 385mL DMF to a round-bottomed flask equipped with a reflux condenser and a drying tube, add 12.36g of sodium styrene sulfonate under stirring conditions, continue stirring for 2 hours, and heat up to 70°C , add 33.2mL KH-570 and 0.175g AIBN in turn, react for 12h, then add 0.175g AIBN, continue to react for 12h, remove 255mL of solvent (DMF) by rotary evaporation, and obtain a polysilicon cross-linked polysilicon with a concentration of 0.26g / mL agent solution. In this example, the molar ratio is sodium styrene sulfonate:KH-570:DMF:AIBN=1:2.3:82.5:0.035.

[0077] (2) Preparation of coating solution: Take 76.9mL (20g) polysilicon crosslinking agent solution, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com