Ultra-thin electrolytic copper foil and preparation method thereof

An electrolytic copper foil and ultra-thin technology, applied in the field of electrolytic copper foil, can solve problems such as difficulty in preparing ultra-thin copper foil, and achieve the effects of being beneficial to industrial large-scale production, good tensile strength and flatness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

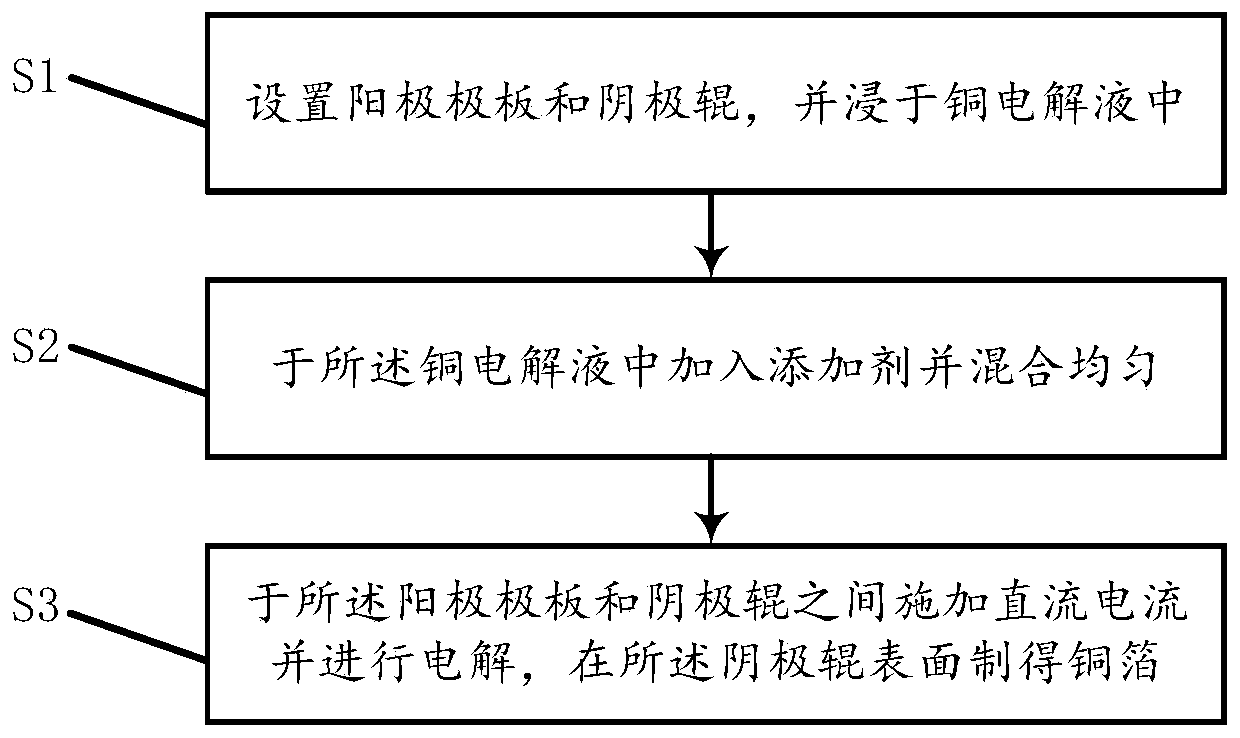

[0016] see figure 1 , figure 1 It is a process flow chart of an embodiment of the method for preparing ultra-thin electrolytic copper foil in the present invention. The preparation method of ultra-thin electrolytic copper foil in the present invention, its steps comprise:

[0017] S1: Set the anode plate and the cathode roll, and immerse in the copper electrolyte. Specifically, the preferred materials and proportions of the anode plate, cathode roll and copper electrolyte in this step are described in detail respectively.

[0018] In this embodiment, the anode plate is an active coating plate, and the active coating plate includes an active coating and a substrate, wherein: the active coating includes noble metals such as palladium, iridium, ruthenium, cobalt, lead, manganese, etc., and the active coating The total amount of precious metal in the layer is not less than 2g / m 2 , and the density of iridium is 0.5~5g / m 2 , the purpose of setting the above-mentioned various p...

Embodiment 1

[0026] S1: choose to contain 2g / m 2 The active coating of iridium and the titanium plate form the anode plate, and the stainless steel roller plated with chrome on the surface is used as the cathode roller. Copper electrolyte is prepared by mixing copper sulfate, sulfuric acid and hydrochloric acid. The copper ion concentration in the copper electrolyte is 60g / L, sulfuric acid 100g / L, the chloride ion concentration is 25mg / L, and the anode plate and the cathode roll are immersed in the copper electrolyte.

[0027] S2: Take an appropriate amount of sodium polydithiodiphenyl sulfonate, sodium N,N-dimethyldithioformamide propane sulfonate, hydroxyethyl cellulose and collagen to make an additive, and the additive is polydithiodiphenyl The concentration of sodium sulfonate is 25 mg / L, the concentration of N,N-dimethyldithioformamide propane sulfonate is 30 mg / L, the concentration of hydroxyethyl cellulose is 25 mg / L, and the concentration of collagen is 120mg / L and a molecular we...

Embodiment 2

[0030] S1: choose to contain 2g / m 2 The active coating of iridium and the titanium plate form the anode plate, and the stainless steel roller plated with chrome on the surface is used as the cathode roller. Copper electrolyte is prepared by mixing copper sulfate, sulfuric acid and hydrochloric acid. The copper ion concentration in the copper electrolyte is 75g / L, sulfuric acid is 120g / L L, chloride ion concentration 35mg / L, immerse the anode plate and the cathode roll in the copper electrolyte.

[0031]S2: Take an appropriate amount of sodium polydithiodiphenyl sulfonate, sodium N,N-dimethyldithioformamide propane sulfonate, hydroxyethyl cellulose and collagen to make an additive, and the additive is polydithiodiphenyl The concentration of sodium sulfonate is 25 mg / L, the concentration of N,N-dimethyldithioformamide propane sulfonate is 45 mg / L, the concentration of hydroxyethyl cellulose is 35 mg / L, and the concentration of collagen is 150mg / L and a molecular weight of 2500,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com