Process for directly electrolyzing waste etching solution to extract copper

A technology for etching waste liquid and waste liquid, which is applied in the field of copper recovery, can solve the problems of high cost, mixing into regeneration liquid, and the problem of acid etching waste liquid regeneration, etc., and achieves the effects of stable performance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

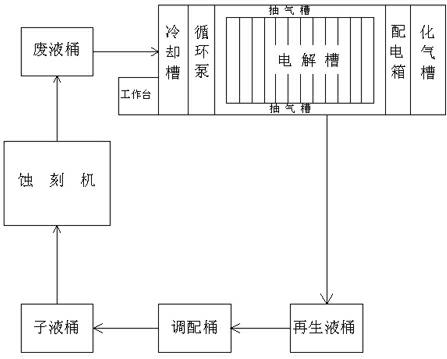

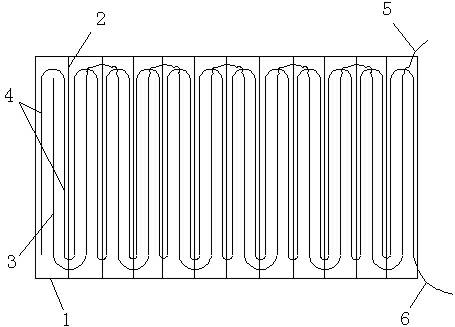

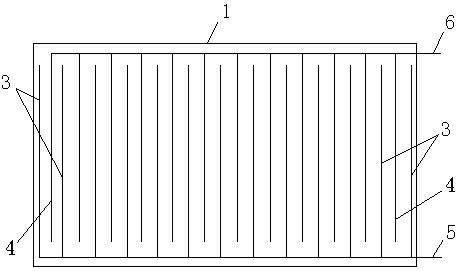

[0015] In this example, refer to figure 1 , figure 2 , image 3 and Figure 4 , the direct electrolytic copper extraction process of the etching waste liquid, the etching waste liquid is the etching waste liquid produced in the PCB board manufacturing process, including alkaline etching waste liquid and acidic etching waste liquid, and the etching waste obtained after etching in the etching machine The alkaline etching waste liquid is stored in the waste liquid barrel, and the copper extraction process of the alkaline etching waste liquid is as follows: the etching waste liquid is transferred from the waste liquid barrel to the cooling tank, and after cooling, it is pumped into the electrolytic cell by the circulating pump for electrolytic copper extraction; The rectifier provides electrolysis power to the electrodes, in which the voltage is 48V and the current is 2500A; the entire electrolytic cell 1 is divided into twelve mutually independent tank chambers by a partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com