Method and equipment for preparing material with multi-color oxide film on surface

A technology of oxide film and anodic oxide film, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of complicated preparation process, achieve the effect of being environmentally friendly and avoiding alkali corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

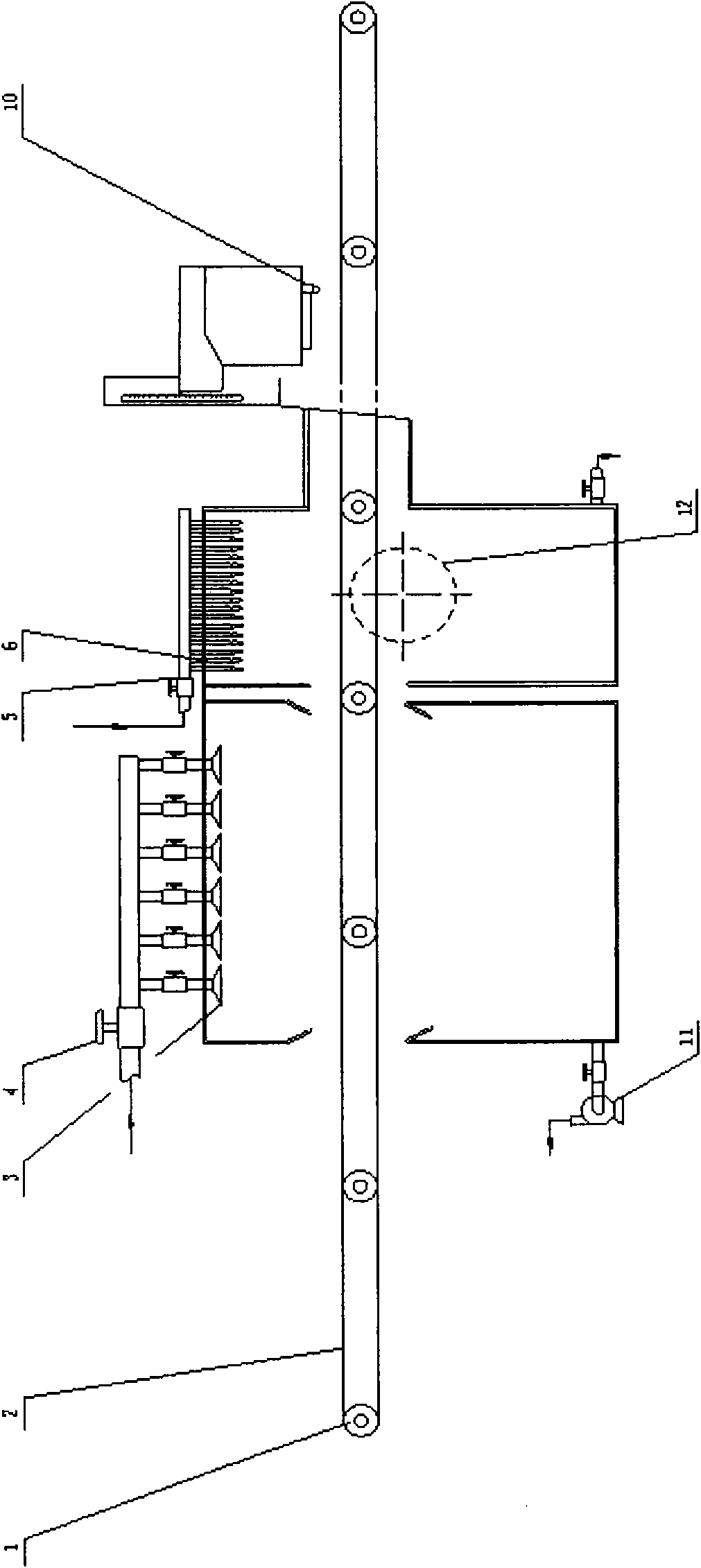

Image

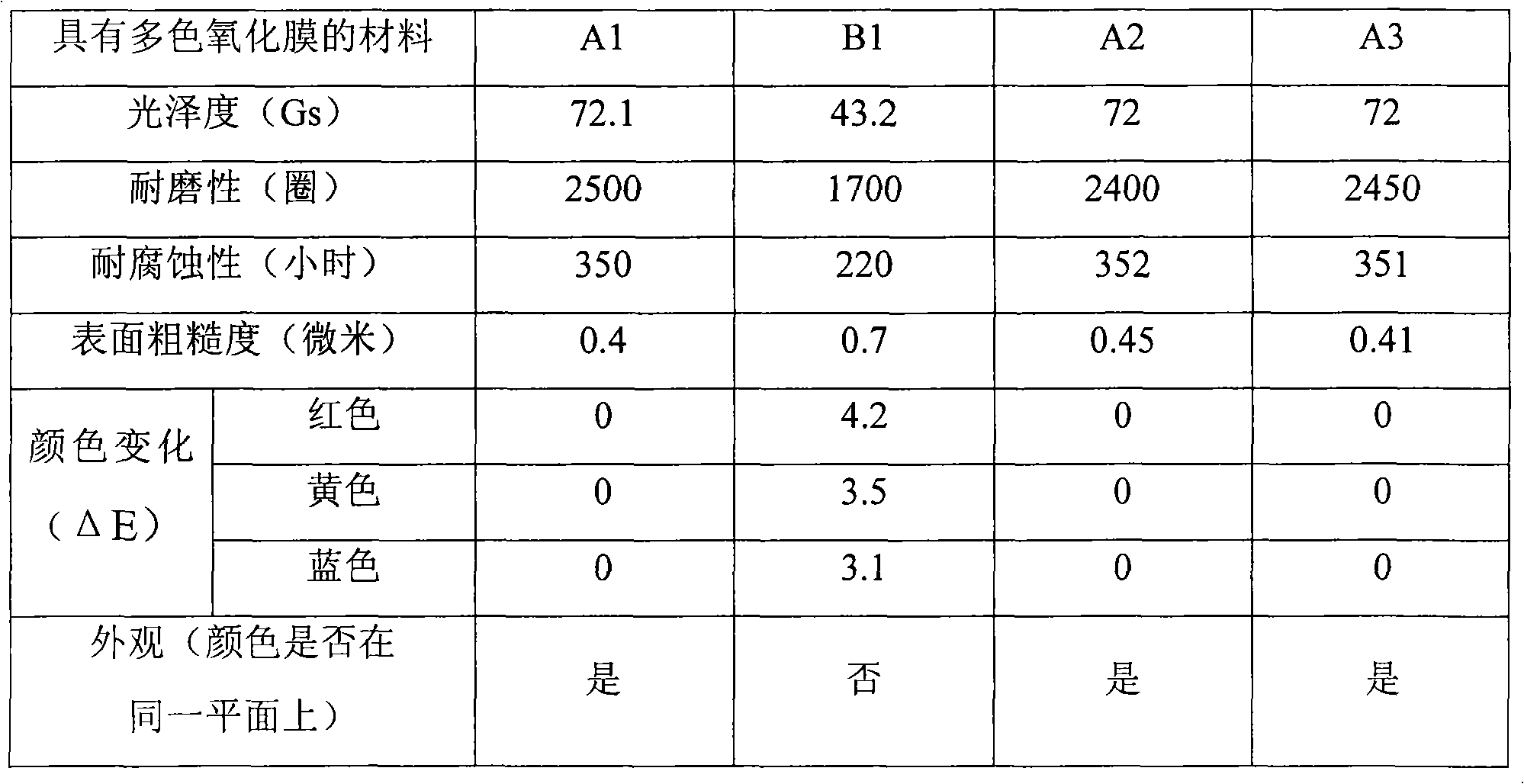

Examples

Embodiment 1

[0043] 1. Pretreatment

[0044] (1) Degreasing and wax removal

[0045] Immerse the aluminum alloy base material of model 6061 in a solution of 40 g / L and a temperature of 60 °C for 5 minutes and then take it out , Wash the alloy degreasing powder on the surface of the substrate with water.

[0046] (2) Alkali etching and neutralization

[0047] The base material after degreasing and wax removal was immersed in a sodium hydroxide solution with a concentration of 60 g / L at 70°C for 20 seconds, and then immediately immersed in water to clean the residual alkali on the surface of the base material. Then the substrate is immersed in the Top Desmut N-20 (Hangzhou Aoye Technology Industrial Co., Ltd.) solution with a pH of 100 g / liter at 25° C. for 10 minutes, and immediately immersed in water to clean the residual TopDesmut N-20 on the surface of the substrate. 20 solution.

[0048] (3) chemical polishing

[0049] The base material after alkali etching and neutralization is im...

Embodiment 2

[0062] According to the method described in Example 1, after pretreatment, anodic oxidation, and dyeing pretreatment were carried out on the aluminum alloy substrate of model 6061, the material A2 with a multicolor oxide film was prepared. The difference was that the preparation had a multicolor oxide film (1) In water washing, drying and coloring, when washing, the pressure of spraying is 0.3MPa, and the time of spraying and washing is 40 seconds; when drying, the temperature of air flow is 30°C, and the speed of air flow is 5 m / s, the drying time is 10 minutes.

Embodiment 3

[0064]According to the method described in Example 1, after pretreatment, anodic oxidation, and dyeing pretreatment were carried out on the aluminum alloy substrate of model 6061, the material A3 with a multicolor oxide film was prepared. The difference was that the preparation had a multicolor oxide film (1) During washing, drying and coloring, when washing, the spray pressure is 0.4MPa, and the spray washing time is 20 seconds; when drying, the temperature of the air stream is 40°C, and the speed of the air stream is 10 m / s, the drying time is 3 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com