Texturing and cleaning medium for the surface treatment of wafers and use thereof

A surface treatment and texturing technology, applied in the directions of non-surface-active detergent compositions, inorganic non-surface-active detergent compositions, organic non-surface-active detergent compositions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

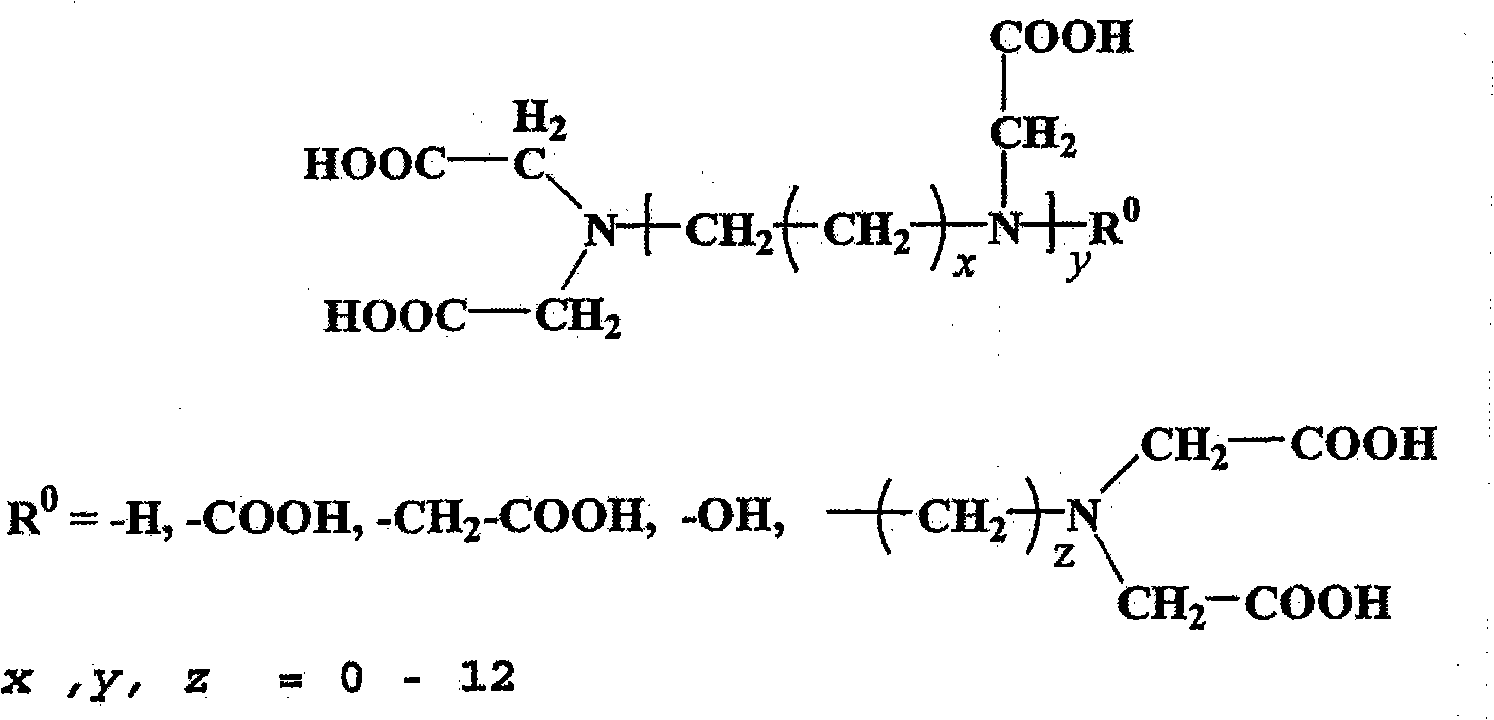

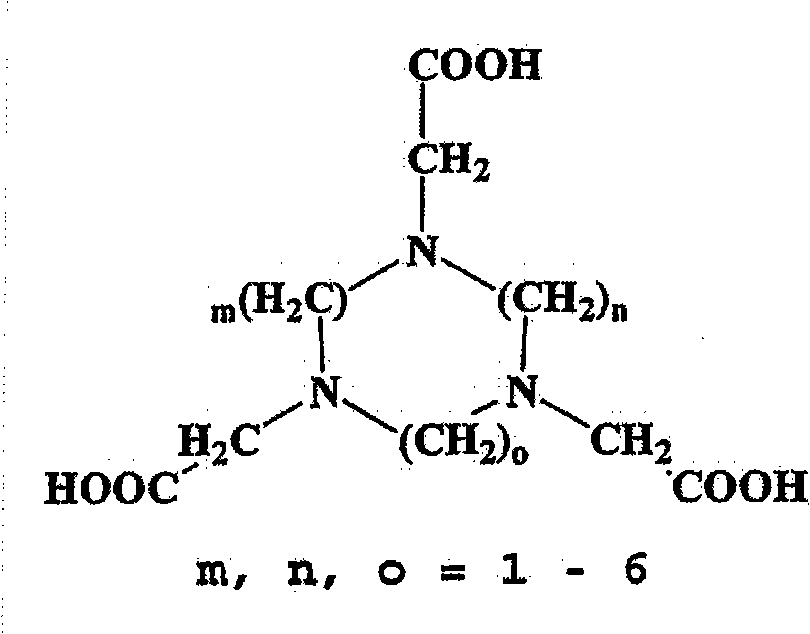

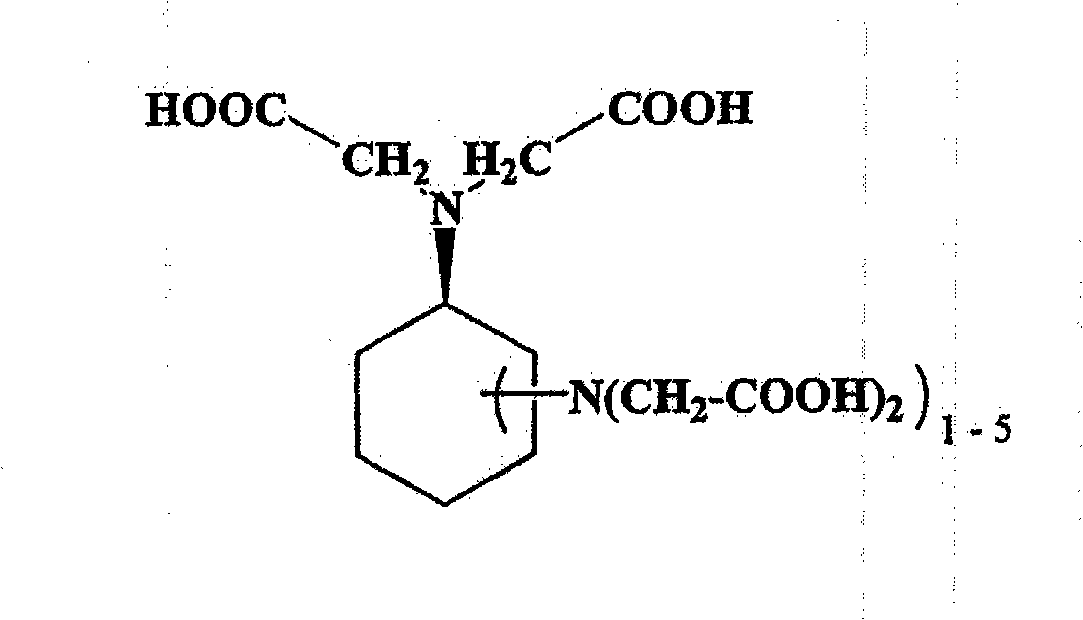

Method used

Image

Examples

Embodiment 1

[0094] Cleaning, damage etching and texturing in one step of a batch process

[0095] An embodiment according to the present invention for cleaning, damage etching, and texturing in one etching step relates to a batch method in which a unit includes four modules, each of which is air-locked in space with each other On separate. Depending on the number of wafers to be processed at the same time, each module contains an externally sealed chamber of different lengths. The chamber is temporarily opened for loading and unloading, which takes up to 10 seconds for each module, and the chamber has the smallest gas space, so that the thermal and chemical equilibrium between liquid and gas phase can be quickly performed.

[0096] In each chamber, there are processing tanks in which the rails can be immersed. At the beginning of the cleaning process, the wafers are fixed on the rails and they move from one processing chamber to another on the rails.

[0097] In each module, perform the follow...

Embodiment 2

[0117] Cleaning and texturing of wafers cut by wire saw

[0118] Another embodiment according to the present invention for cutting a wafer with a textured wire saw and cleaning at the same time relates to a batch method in which an etchant is used in the module 2 which contains at most 3.5 relative to the total amount of the solution. Weight% potassium tosylate (potassium salt of p-toluenesulfonic acid), 1 weight% potassium tartrate (potassium salt of tartaric acid), 4 weight% potassium hydroxide, and 2 weight% 2-propanol. The processing time in module 2 is 21-25 minutes, and the solution temperature is about 80-85°C.

Embodiment 3

[0120] Cleaning and texturing of wafers cut by wire saw

[0121] Another embodiment according to the present invention for cleaning and texturing wire saw cutting wafers relates to a batch method in which an etching medium is used in module 2 which contains up to 3.5% by weight relative to the total amount of the solution Of potassium tosylate, 1% by weight of ammonium citrate, 5% by weight of potassium hydroxide, 3.5% by weight of 2-propanol and 0.5% by weight of The processing time in module 2 is 21-25 minutes, and the solution temperature is 82-85°C.

[0122] In module 4, the first tank is filled with 5 wt% HCl solution, and the tank temperature is 35°C. The immersion time is 2 minutes.

[0123] The remaining test parameters are similar to those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com