Medium temperature curing high temperature resistant phenolic adhesive

A curing type, high temperature resistant technology, used in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of poor temperature resistance, high curing temperature of phenolic adhesives, and achieve good bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

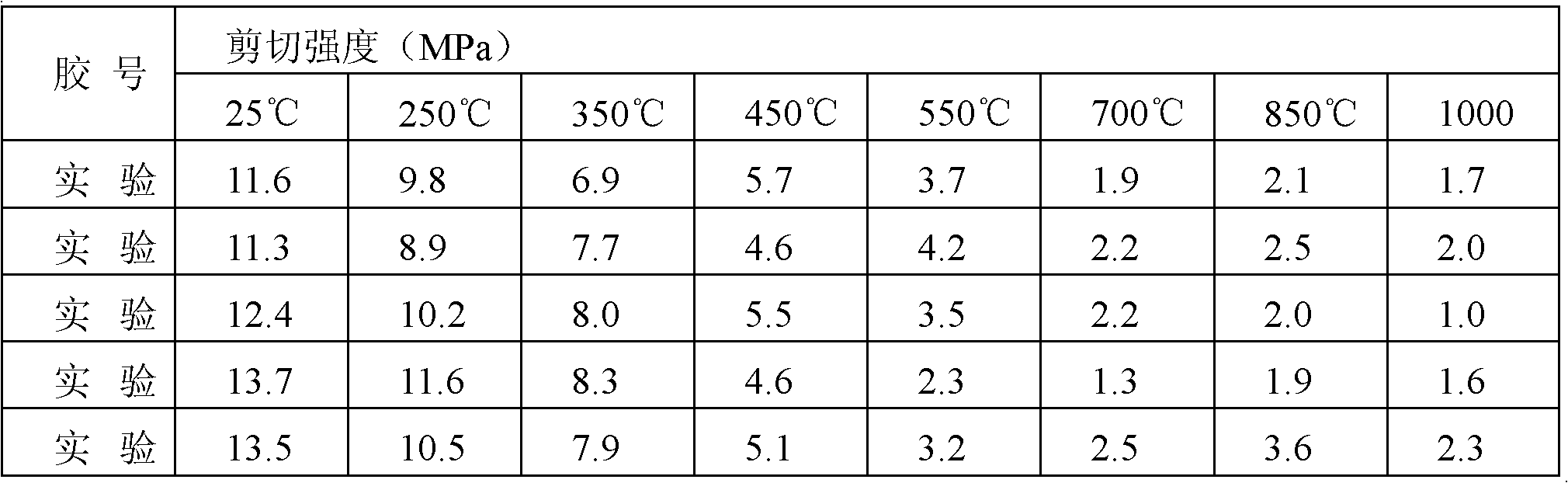

[0015] Specific embodiment one: In this embodiment, the medium-temperature curing type high-temperature-resistant phenolic adhesive is composed of 100 parts by mass of modified phenolic resin solution, 5-40 parts of toughening agent, 10-55 parts of curing agent, 20-100 parts It is made of heat-resistant reinforced resin and 50-400 parts of filler.

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the toughening agent is nitrile rubber, polyvinyl alcohol, polyvinyl furfural, polyvinyl butyral and polyvinyl furfural One or a mixture of several aldehydes. Others are the same as in the first embodiment.

[0017] When the toughening agent described in this embodiment is a mixture, the ratio of each component is arbitrary.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the curing agent is hexamethylenetetramine or paraformaldehyde. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com