Method for preparing high phase ratio electric leakage resistant tracking index leadless compatible CEM-3 copper-clad laminate

A tracking index, CEM-3 technology, applied in the field of electronics, can solve the problems of low heat resistance, resin greasy dirt, large thermal expansion coefficient, etc., to achieve good CAF resistance, high heat resistance, high heat resistance and electrical The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

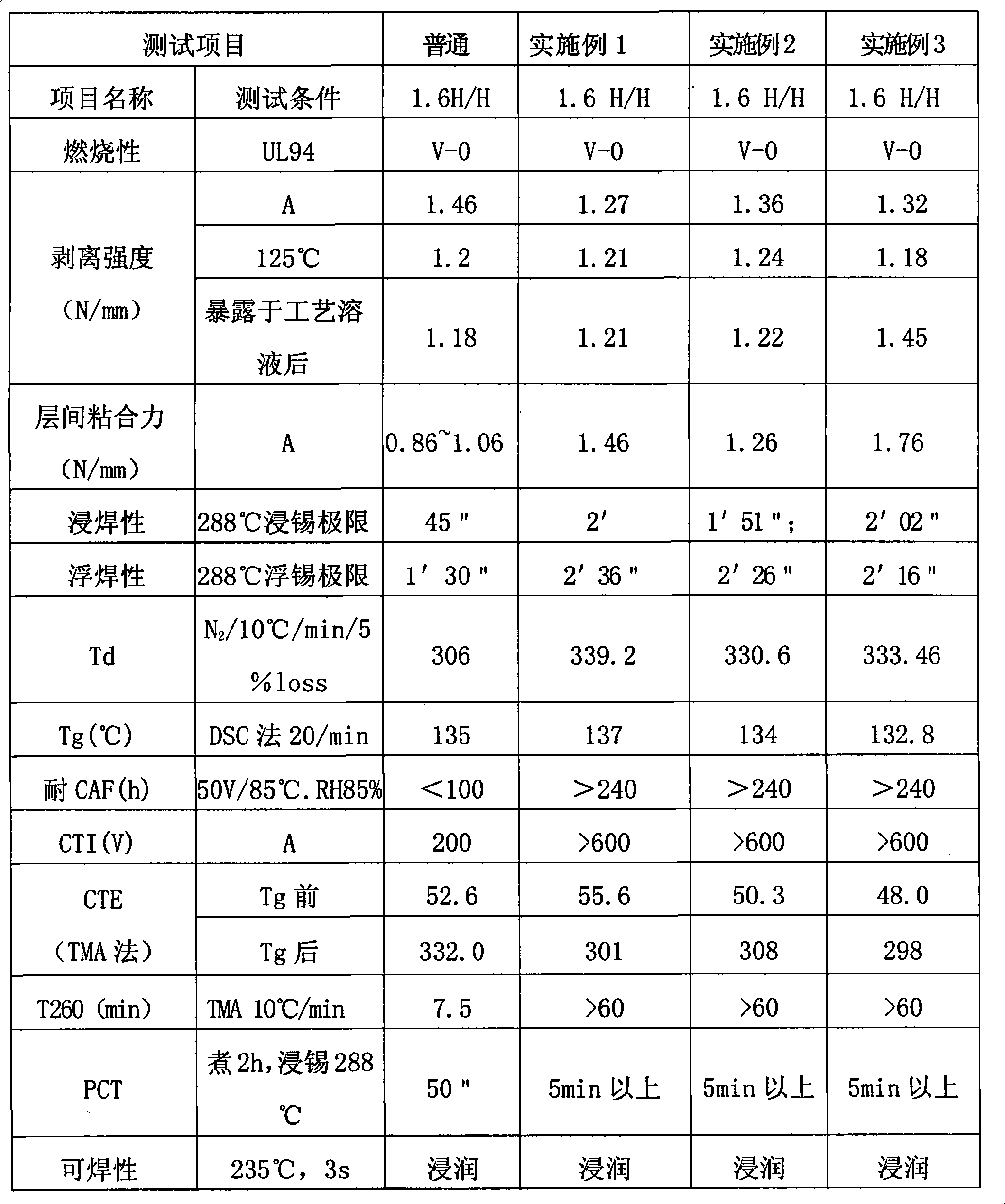

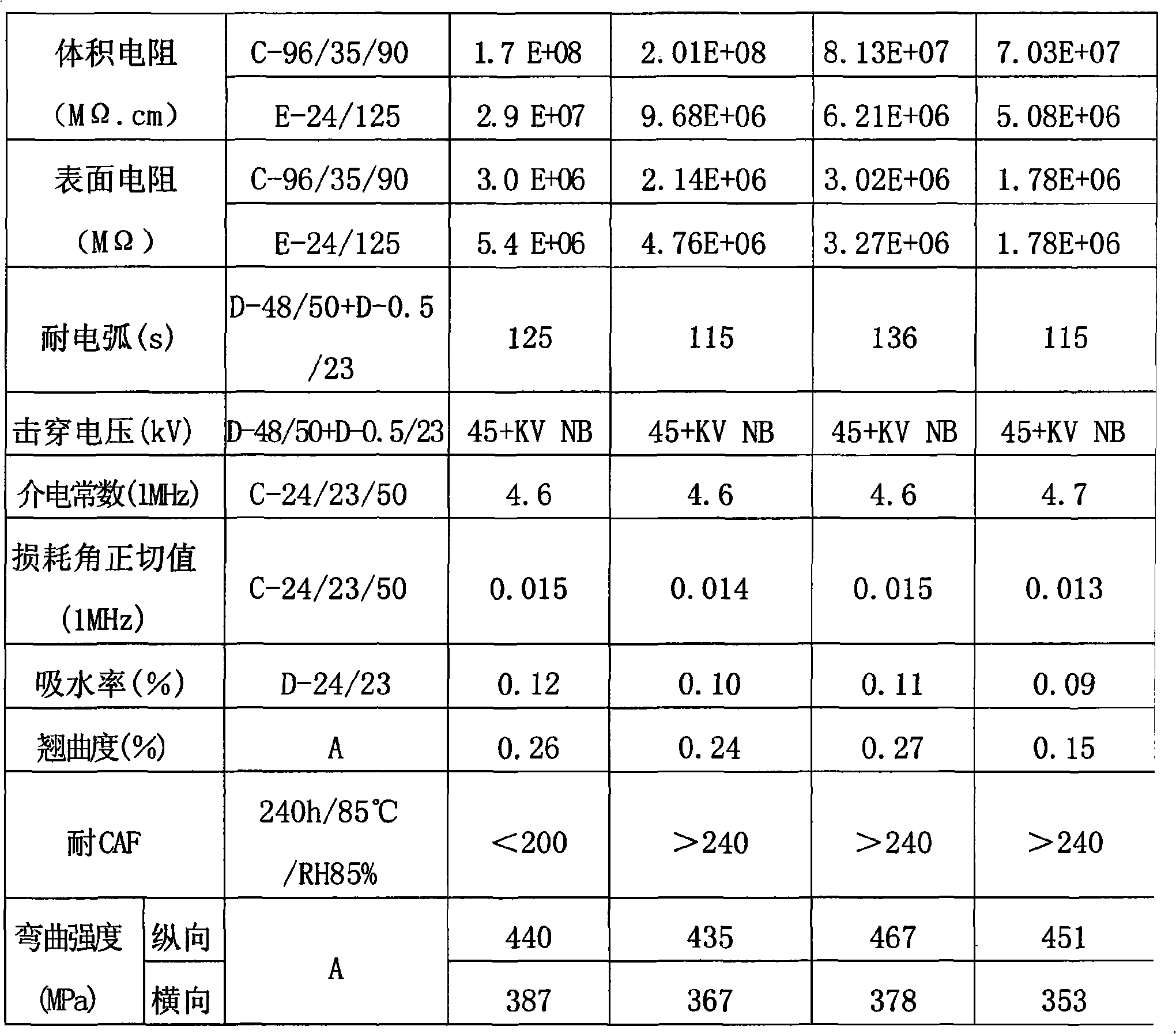

Examples

Embodiment 1

[0014] a. prepare core material resin, its component parts by weight are:

[0015] 100 parts of bisphenol A type epoxy resin, 10 parts of novolak type bisphenol A epoxy resin,

[0016] 25 parts of phenolic resin, Al(OH) 3 40 copies,

[0017] 60 parts of silica powder, 0.1 part of 2-ethyl-4-methylimidazole,

[0018] Modulate the above materials with methyl ethyl ketone to make a resin solution for the core material;

[0019] b. Impregnate glass fiber paper with the above resin solution, and make core material after drying at 175°C;

[0020] c. prepare fabric resin, its component (weight part) is:

[0021] 70 parts of bisphenol A type epoxy resin, 15 parts of nitrogen-containing novolak type phenolic resin

[0022] 30 parts of brominated epoxy resin, Al(OH) 3 30 parts, 0.2 parts of 2-ethyl-4-methylimidazole

[0023] Modulate the above materials into a resin solution for fabrics with methyl ethyl ketone;

[0024] d. Impregnate 7628 fiberglass cloth with the above resin so...

Embodiment 2

[0027] a. prepare core material resin, its component parts by weight are:

[0028] 100 parts of bisphenol A type epoxy resin, 10 parts of novolak type bisphenol A epoxy resin,

[0029] 25 parts of phenolic resin, Al(OH) 3 40 copies,

[0030] 60 parts of Kaolin, 0.1 part of 2-ethyl-4-methylimidazole,

[0031] Modulate the above materials with methyl ethyl ketone to make a resin solution for the core material;

[0032] b. Impregnate glass fiber paper with the above resin solution, and make core material after drying at 175°C;

[0033] c. prepare fabric resin, its component (weight part) is:

[0034] 70 parts of bisphenol A type epoxy resin, 15 parts of nitrogen-containing novolak type phenolic resin

[0035] 30 parts of brominated epoxy resin, Al(OH) 3 30 parts, 0.2 parts of 2-ethyl-4-methylimidazole

[0036] Modulate the above materials into a resin solution for fabrics with methyl ethyl ketone;

[0037] d. Impregnate 7628 fiberglass cloth with the above resin solution ...

Embodiment 3

[0040] A. prepare core material resin, its component (weight part) is:

[0041] 100 parts of bisphenol A type epoxy resin, 10 parts of novolak type bisphenol A epoxy resin,

[0042] 25 parts of phenolic resin, Al(OH) 3 40 copies,

[0043] 60 parts of magnesium hydroxide, 0.1 part of 2-ethyl-4-methylimidazole,

[0044] Modulate the above materials with methyl ethyl ketone to make a resin solution for the core material;

[0045] b. Impregnate glass fiber paper with the above resin solution, and make core material after drying at 175°C;

[0046] c. prepare fabric resin, its component is:

[0047] 70 parts of bisphenol A type epoxy resin, 15 parts of nitrogen-containing novolak type phenolic resin

[0048] 30 parts of brominated epoxy resin, Al(OH) 3 30 parts, 0.2 parts of 2-ethyl-4-methylimidazole

[0049] Modulate the above materials into a resin solution for fabrics with methyl ethyl ketone;

[0050] d. Impregnate 7628 fiberglass cloth with the above resin solution and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com